Sujan CooperStandard chalks out aggressive mid-term growth plan

Mumbai-based supplier targets Rs 400 crore turnover by 2022. Their products claim to achieve 50 percent weight reduction versus metal-based AVS solutions.

Mumbai-based Sujan Cooper Standard (SCS), a joint venture between India’s Sujan Group and the US-based CooperStandard, has chalked out an aggressive growth strategy for the mid-term. The 10-year-old company, which specialises in the manufacture of anti-vibration systems (AVS), aims to double its current turnover of Rs 190 crore over the next five years.

Revealing his company’s plans in an exclusive interaction with Autocar Professional, Vijay Sujan, CEO of Sujan CooperStandard, disclosed, “At present, we are at Rs 190 crore in our turnover and looking at a turnover of Rs 230 crore in FY2019. We plan to double this over the next five years. Over the mid-term, we plan to diversify into the commercial vehicle sector as well as exports in a major way, leveraging our own strengths and connect with CooperStandard, our joint venture partner.”

CooperStandard is a US$ 3.47 billion (Rs 25,152 crore) (CY2016) auto component major specialising in four product groups that include anti-vibration, sealing, fuel and brake delivery and fluid transfer. The company has two joint ventures with the Sujan Group of India to locally manufacture and supply anti-vibration systems and fluid transfer systems. The latter is known as Polyrub CooperStandard.

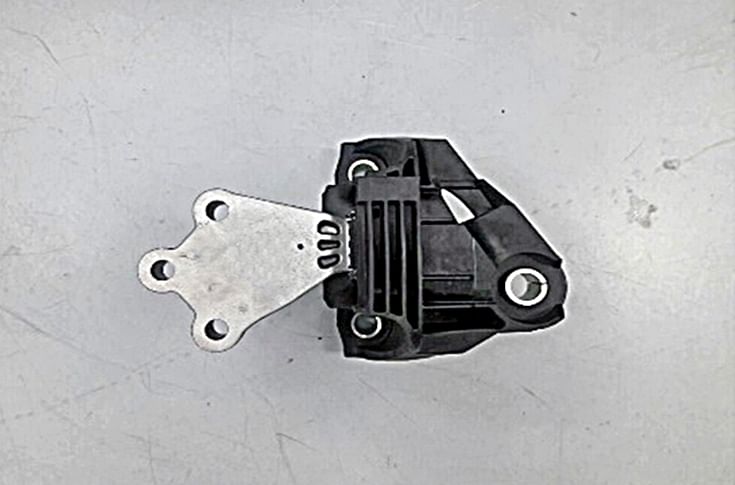

Hydro engine mount with plastic housing weighs 10 percent less than conventional part. SCS supplies it to Ford India.

What's interesting is that both firms (Sujan Group and CooperStandard), under their new revised strategy, have a unified approach of one company, one brand while reaching out to their new and existing customers in India.

Under its anti-vibration systems portfolio, SCS manufactures and supplies right and left engine mounts, body mounts, multi-link axle bushes, twist beam bushes, and several other components. SCS is a Tier 1-cum-Tier 2 supplier across the different automotive components it manufactures currently.

Notably, SCS is the only supplier of hydro engine mounts with plastic housing in India. The uniqueness of this product is the plastic housing, which replaces steel or aluminium and thereby reduces the overall weight of this component by about 10 percent. The company currently supplies this product to Ford India.

Sujan CooperStandard AVS has two manufacturing plants in India at Chakan and Chennai. While the Chakan facility is the mother plant for the JV, the Chennai plant was set up for Renault-Nissan. Other major customers for SCS include Mahindra & Mahindra, Tata Motors, Maruti Suzuki, FCA and others.

Daily review meeting with cross-functional team on shopfloor.

Under its aggressive mid-term plan, the company has planned several new product introductions, which it will roll out over the next three years. Talking about the potential growth drivers, the CEO added, “India’s growing B segment and the SUV/UV business are driving growth. Moreover, customers are now shifting from conventional to hydraulic mounts for mid- and high-end segment cars. There is also a shift from natural to synthetic rubber for

weight and space reduction. We are well positioned to take on these challenges. At SCS, we have been able to reduce the time-to-market introduction in bringing products to India and wish to do the same for our future portfolio.”

Chakan plant: R&D & production unit

Spread across more than 100,000 square feet, SCS’ Chakan facility is located close to its key customers. According to the company, the plant uses 175 tonnes of rubber compound, despatching about 1.5 million parts every month across 162 basic product categories under AVS. The plant employs about 550 people in different roles including engineers involved in R&D activity.

SCS sole vendor of hydro engine mounts with plastic housing.

"At SCS, you will see 4M (Man, Machine, Material and Methods) in equilibrium, aiming to make the best anti-vibration products in the auto sector with the latest technology,” says Dinesh Pawar, COO at Sujan CooperStandard AVS.

The R&D division, which currently has a team of 36 engineers (under AVS), is scheduled to expand to 48 engineers by 2020 and 56 engineers by 2021, points out Pawar, who is responsible for streamlining the operations at the Chakan unit following global manufacturing processes and standards.

The degreasing and phosphating line at SCS' modern facility.

Carrying out the core manufacturing operations at the Chakan plant are the injection rubber moulding press machines – 250-tonne, 400-tonne and 110-tonne presses – which are used for prototyping, design and validation of initial products.

One of the most interesting sections on the shop floor is an automated robotic line, set up in June last year exclusively for Ford India. The line can roll out about 1,300-1,400 units of the lightweight hydro engine mounts with plastic housing in 24 hours, operating at 100 percent capacity. “The automated robotic line brings consistency in our products, which is the hydro mount in this case. It ensures precision and quality while assembling different parts into one unit within the given time,” underlines Pawar.

“Currently with three shifts, we are working at 80 percent capacity at Chakan. We can add more machines to increase the production capacity further when required. Our focus is to maintain good productivity and efficiency in our plant operations,” he adds.

With India's passenger vehicle industry currently firing on all cylinders, Sujan CooperStandard AVS is bullish on future growth. While it plans to also cater to the commercial vehicle sector, which is logging handsome growth, and enhance exports too, the company is now eyeing business from the nascent electric mobility industry in the country. Its JV partner, CooperStandard is a leader in providing motor mounts for EVs and SCS is well positioned to introduce them in the Indian market after localising them.

(This article was first featured in the 1 July 2018 issue of Autocar Professional)

RELATED ARTICLES

Beyond Cars: VinFast's Full-spectrum EV Push in India

With $2 billion committed, VinFast is constructing an integrated play spanning cars, scooters, buses, ride-hailing and c...

A Breather for Hero

A combination of policy tailwinds, new products and Honda’s cautious approach on EVs put a stop to the constant encroach...

Renault India's Quiet Fixer

As the head of Renault India, Francisco Hidalgo Marques faces his biggest challenge yet.

10 Sep 2018

10 Sep 2018

44773 Views

44773 Views

Kiran Murali

Kiran Murali