Hella India Automotive plots a slew of tech-laden new products

The Dhankot-based supplier is now offering complete solutions to OEMs and its future growth strategy involves developing a host of technology-integrated products designed to improve efficiency, comfort and handling in vehicles.

With OEMs increasingly scouting for integrated solutions, component suppliers like the Dhankot-based Hella India Automotive are doing just that. The company has, since the past four years, been gradually shifting its focus towards a systems approach by integrating electronics into the vehicle instead of simply making electronic components.

Simply put, this means it is now offering a complete solution to OE manufacturers wherein the electronics device cannot be sold as a separate product in the aftermarket but more as an integrated solution like the body control module, remote keys and keyless entry at the OE’s end.

With new emission regulations coming into force in India by 2020 and electric vehicles along with eco-friendly automobiles set to get a boost, Hella India has drawn a roadmap for the next three years. This future growth map encompasses developing technology products that offer an edge in fuel efficiency, besides integrated electronics and e-mobility solutions.

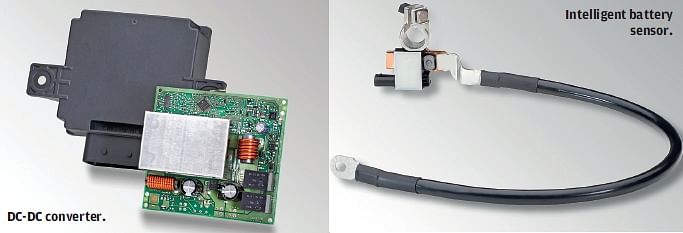

A visit to the company’s Dhankot plant, near Gurgaon, is an eye-opener. Hella is currently developing a DC-DC converter which will be rolled out not only for domestic applications but also for global markets and will ride on the back of the government’s Make-in-India mantra. Daimler Trucks has already awarded business for the DC-DC converter to Hella and production is to commence by the year-end. The electronic product will be exported to Daimler globally as well after being supplied in the local market.

In fact, the company’s growth strategy involves rolling out 2-3 new products this year that it is currently developing at its global R&D centre for electronics in Pune. When completed, these will be manufactured at the Dhankot facility.

“The DC-DC converter order will be close to euro 30 million and will be a fitment for all Daimler trucks. Starting with an India order worth euro 20 million, exports will kick off to Russia and other countries after 5-6 months of local consumption,” Karan Kumar Anand, deputy managing director and in charge of plant management at Hella India Automotive, told Autocar Professional in an exclusive interaction recently.

Usually product design that runs over 8-9 months commences after the nomination by the customer and is followed by product and process validation. As part of this shift from the component approach to the systems approach, next in line is the development of smart mood lighting which is integrated with the vehicle through a smartphone and can change the interior lighting colour based on the occupant’s mood and speed zone. It is being developed for a passenger car OEM and will be a comfort product; it is also slated for a rollout this year.

Betting big on Electronics

Also in the pipeline is an advanced technical electronic steering unit with an electronic controller for which Hella is in talks with various vehicle manufacturers and expects to launch it within a year. The product senses the driver’s intention electronically through sensors and accordingly converts the mechanical force into the turning angle.

The electronic steering unit is already available globally and Hella is working to localise it for some OEMs with production to kick off by mid-2017, initially for an off-road vehicle. Plans are underway to slowly move its use to passenger cars as well. But for now the electronic steering unit will be developed in India for the export market for the off-roader.

In addition, among other electronics offerings will be an intelligent battery sensor which is currently under use by OEMs in Asia. The sensor senses the health of the battery and will be a useful addition to vehicle manufacturers’ portfolio in the shift towards e-mobility and electric vehicles. A small device, the intelligent battery sensor is ready and waiting for market demand for its unveiling. To be imported, it will see some additional customisation work after which it will be indigenously manufactured at Dhankot where the company’s horn and electronics facility is located.

At present, Hella has one facility for manufacturing electronics products and is exploring an alternative manufacturing location which could probably be a toss between a site at Pune in close proximity to its R&D centre or in neighbouring Gujarat.

Anand says the new plant will be finalised within two years as the existing factory has adequate capacity of 1.2 million units per annum for the body control module and remote keys. Hella will be adding smart mood lighting and the DC-DC converter shortly to the plant’s production in addition to which it has a production capacity of 10 million horns annually with capacities varying according to the product stream.

For instance, the headlamp actuator produces four million units annually. In horns also, Hella is looking to graduate from electro-mechanical horns to electronic horns which will have a printed circuit board within. It has already bagged an order for the e-horn that kicks off production this October and will ensure an unlimited lifespan and no wear and tear for the electronic horn compared to the electro-mechanical horn which has a 2-3 year timeframe.

There is a major market in Asia and India for this product with many OEMs already importing it. Hella, which is very strong in its 10 percent of its revenue annually on R&D globally as well as in India. About 250 of its manpower strength is engaged in lighting R&D at Chennai in addition to 250 who are deployed at Pune for electronics development work. Besides, 60-70 people are involved in component R&D at Gurgaon.

In terms of its manufacturing strength in electronics and horns, Hella’s Dhankot facility currently has two assembly lines for making electronics products. The earlier surface mounted technology (SMT) assembly line was of the older version. About three years ago, the new state-of-the-art SMT line was installed at the plant which the company claims is the best in the country and comparable with any of Hella’s global locations.

Globally, the German component maker is an electronics giant holding a 55 percent market share in a key product like the accelerator pedal sensor which in India commands a 80-85 percent share due to its high technology.

It started manufacturing the accelerator pedal sensor around seven years ago and is a single source for many carmakers like Maruti Suzuki and Tata Motors.

The component supplier is also tweaking its fuel control module product line that betters fuel efficiency by 2-3 percent in a vehicle to be able to meet upcoming BS-VI emission norms. Providing fuel on demand, the module helps burn less fuel at stops or red lights and forms an integral part of the fuel injection system. It has been developed globally and some OEMs in India are trying out some of the Hella samples at present with rollout expected over the next two years to meet the new regulations.

Hella’s advanced engineering team in Pune has also developed a tyre pressure monitoring system as also the throttle position sensor that forms part of the fuel delivery system. The device controls the air in the engine cylinder and the fuel injection system which controls the supply of fuel. Another product is the emission control wastegate actuator that uses gases which are wasted in recirculation. Once Euro-VI regulations come into force, the global platform will be adopted to meet local needs.

The next couple of years will see a lot of customisation work on electronics systems for meeting BS-VI emission norms as well as safety regulations and will all be manufactured locally. Anand admits that the company will look at localisation of these electronics systems once volumes reach critical mass of around half a million and start getting accessed for different vehicle platforms.

In India, Hella has been investing a capex of euro 5 million yearly for the past three years. This is expected to be stepped up to euro 7 million over the next three years on rising electronic development at Pune as well as on local manufacturing.

Most of the new electronics products that are imported will undergo modifications in India for example the electronic steering unit that is moving from hydraulics to electronics.

Maruti Suzuki is a key customer with Hella supplying about 85 percent of their demand for the accelerator pedal sensor (APS). Tata Motors is another client for remote keys and the body control module as are many others. Recently, Hella has bagged an order from Honda Cars India as well for the APS for the new Brio hatchback to be supplied in Thailand and in India. Earlier, it was a supplier of horns to Honda.

Safety kit

On the automotive safety front, some interest has been generated by OEMs in advanced driver assistance systems but these products are currently not being considered for India but are more popular globally. The past six months have seen a lot of movement in terms of sensors and Hella is in an advanced stage of developing the 360deg sensing device as well as radar products globally.

Autonomous vehicles are an upcoming trend where vehicles can sense the distance of oncoming vehicles or people through cameras and 360deg sensors that are placed on the outside rear mirrors.

Driver drowsiness systems that beep alarms is another trend overseas but are still some time away in India. Cost pressures of such electronics systems necessitate high volumes and local development to tap economies of scale.

Interestingly, due to its tilt towards technology, Hella India has been nominated for the ACMA gold award for technological excellence at the annual ACMA convention this year. Despite the subdued growth in the industry, Hella India grew 30 percent last year and is eyeing a CAGR of 30 percent over the next three years.

With its product innovations, Hella India is currently worth Euro 45 million in India in electronics and horns and has an ambitious target of reaching euro 100 million over the next three years with the fillip given to its electronics domain. From the earlier 35-40 percent of revenue contribution from the horn division, today the equation has shifted to 25 percent and may tilt further to 20 percent in favour of horns with the balance coming from electronics as cars get more sophisticated and technology-laden going forward.

You may like: Hella India Lighting invests big in plant modernisation

RELATED ARTICLES

A Breather for Hero

A combination of policy tailwinds, new products and Honda’s cautious approach on EVs put a stop to the constant encroach...

Renault India's Quiet Fixer

As the head of Renault India, Francisco Hidalgo Marques faces his biggest challenge yet.

Tesla’s Test

Unlike in other markets, Tesla has taken a long-game approach in India, focusing on creating the infrastructure first.

By Shobha Mathur

By Shobha Mathur

24 Sep 2016

24 Sep 2016

16865 Views

16865 Views