Continental Automotive Systems eyes operational expansion at Chakan unit

Continental Automotive Systems’ Chakan facility, which makes & supplies fuel delivery modules and fuel rail assemblies, to see operational expansion via new orders in domestic & export markets, and venturing into fuel delivery units for 2W.

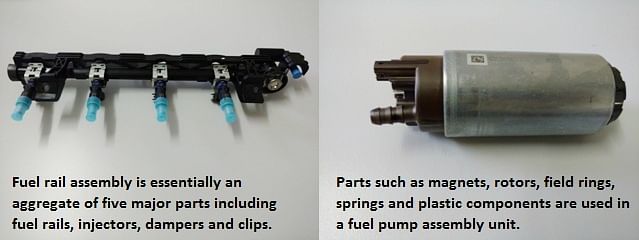

Continental Automotive Systems’ production plant in Chakan assembles and supplies only two product assemblies currently. These are fuel delivery modules (FDMs) and fuel rail assemblies. The two product lines are positioned in Continental’s large umbrella of powertrain division and fuel and exhaust management business unit (FEM - BU) within the former’s domain.

Both these crucial parts are used on the scale of one unit per passenger car. This clearly translates into the market size equivalent to that of the passenger car industry.

While the FDMs that are currently assembled at the plant are for diesel cars, the fuel rail assembly unit is for petrol vehicles. The company, along with its customers, designs, develops and validates these products at its Bangalore-based facility. The Chakan unit, on the other hand, is engaged in the manufacturing operations and currently employs around 170 people.

In an exclusive interaction with Autocar Professional, Anurag Garg, head – BU FEM, India & ASEAN, Continental Automotive Components India, says, “Given our existing production capacity of the FDMs, we can easily cover the majority of the existing passenger car market from this plant. While currently we are running one shift a day, it can be increased up to three shifts per day in order to cater to the increase in demand.”

This business unit of Continental Corporation competes primarily with some of the multinational powertrain component suppliers present in India such as Bosch, Denso, Delphi and others. Continental, according to the senior official, was a late entrant in this domain and inaugurated its production plant in Chakan in 2012.

According to a dated official company release, Continental has invested approximately two million euros bringing this project on stream.

“The company has already delivered the first batch of fuel pumps to a customer and is currently in the process of expanding the scope of this localisation program to other customer lines including both gasoline and diesel gerotor pumps,” quotes the official release from May 2013.

Elaborating on the operations at this facility, Garg says: “We began with localising the pump assembly unit with vertical integration on the pump side. So localising that part, which is the heart of an FDM unit, gave a strong lead in the industry. With a focus on developing the products, we developed competencies, which have also helped our other production units. Teams from our OEM customers frequently visit the facility to oversee our capabilities.”

Three pillars of growth

Garg, along with his team, has chalked out a three-pillar growth strategy that will not only expand the production operations at the Chakan plant but will also boost the business prospects in the coming years.

“We have a three-pillar strategy in place that will drive growth for us in the near future. Firstly, we plan to increase our business in the domestic market by bagging more orders for FDMs from the domestic OEMs for petrol cars. While we are frontrunners in FDMs, we aim to step into the petrol FDM space. Secondly, we are planning to start exporting one of these products very soon. We are aggressive with our exports to the ASEAN locations,” mentions Garg, disclosing his plans.

“Thirdly, we are looking to venture into the two-wheeler segment. With BS VI emission norms coming by 2020, we believe two-wheelers will need engine systems which will create the requirement for fuel pumps. As we know that this market is primarily dominated by 150cc or smaller models, we are looking at the potential of two-wheeler fuel pumps for models above 150cc. We are working on developing these pumps and our target is that by 2019 we should be able to give the products to our customers for their trial exercises.”

Exports to ASEAN markets

Garg and his team are planning to begin exports of fuel pumps from the Chakan plant as early as in the next 3-4 months. “We are also working with our ASEAN customers. In six years, we have turned around our competencies from scratch to supporting our own foreign plants. While we can now support other locations, this capability can also help us attract additional export business. Within three months, we will begin our exports for FDMs and the pump assembly line will run three shifts,” adds Garg.

On the two-wheeler front, the company is likely to make further investments at the Chakan plant. These fuel delivery units are expected to be designed and developed locally. “The plan is in its elementary stage as of now,” he says.

According to Garg, who estimates that the production capacity at Chakan plant will suffice until 2018-19 as planned, there are possibilities of further backward integration to boost the scale of localisation within the existing product lines.

“Almost 70 percent of child parts are currently imported from essentially the same suppliers who supply Continental on a worldwide scale. For example, we are importing crucial parts such as the armature, which is being imported from Mexico. It takes about 12-15 weeks in transit. Further, we see the technology evolving in the mature markets of USA and Europe while India might continue to use the same for another decade. We could also see an internal shifting of production lines from one of those markets to the Chakan facility in the foreseeable future,” he sums up.

RELATED ARTICLES

Hyundai: Going Beyond Business

Hyundai Motor India sets an example for manufacturing companies across the country with its extensive and impactful soci...

Pawan Goenka: From Rural Madhya Pradesh To India's Space Corridors

The story of Pawan Goenka's life mirrors that of India's ascent—humble beginnings, bold bets, and a mission to make Indi...

M&M and SML Isuzu: Strategy, Synergy, and Game Plan

Mahindra & Mahindra has acquired SML Isuzu, a key player in the small and medium sized CV market in India. But can this ...

By Amit Panday

By Amit Panday

18 Jun 2016

18 Jun 2016

30638 Views

30638 Views

Shahkar Abidi

Shahkar Abidi