Toyota uses tech from Mirai FCEV to accelerate factory decarbonisation

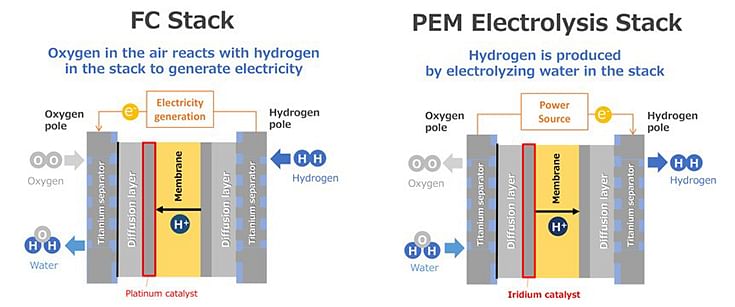

Toyota has developed new electrolysing equipment that produces hydrogen from water, using the fuel cell stack and other technologies from the Mirai fuel cell electric sedan.

Toyota is working with industry partners to use hydrogen and renewable energy to decarbonise factories. It has recently developed new electrolysing equipment that produces hydrogen from water, using the fuel cell stack and other technologies from the Mirai fuel cell electric sedan.

This equipment will be put into operation this month (March 2023) in a Denso plant in Japan and will serve as a working demonstration designed to help promote its wider uptake in the future. Toyota is accelerating its work with Japan’s Fukushima prefecture to develop future cities, building a model for local hydrogen production and consumption. Using electrolysis equipment produces clean hydrogen that can be burned in one of the Denso plant’s gas furnaces.

Toyota has positioned hydrogen as a critical fuel for initiatives aimed at reducing CO2 emissions and contributing to the drive towards carbon neutrality. It is promoting hydrogen use not only through fuel cell electric vehicles (FCEVs), including passenger cars, trucks and buses, but also through the use of fuel cell (FC) products, such as stationary generators. To this end, it is working with industry partners in areas of hydrogen production, transportation, storage and usage.

Stack usage – FC and electrolysis

Stack usage – FC and electrolysis

Pushing the hydrogen tech envelope

Toyota itself is using hydrogen for FCEVs, stationary generators and production purposes. It has also promoted other activities such as the development and manufacture of FC trucks to transport hydrogen. In the future, it hopes to contribute to expanding the options for hydrogen production, using biogas generated from livestock manure, in addition to developing electrolysis equipment.

The electrolysis equipment has been newly developed, using the FC stack featured in Toyota’s Mirai sedan and Sora FC bus. It benefits from both the technology Toyota has cultivated over many years of FCEV development and the knowledge and expertise it has accumulated from the technology’s use in different working environments worldwide.

Its key features are:

- The cells in the Proton Exchange Membrane (PEM) electrolysis stack are highly reliable, backed by the mass production and usage results from more than seven million (enough for approximately 20,000 FCEVs) produced since the launch of the first Mirai in December 2014.

- Toyota uses titanium for the stack separator, developed to improve the durability required of electrolysis equipment. Titanium is highly resistant to corrosion, maintaining almost the same level of performance after 80,000 hours of operation.

- More than 90% of the FC stack components used for FCEVs and FC stack production facilities can be used or shared in the production process for PEM electrolysis stacks. This allows mass production at a cost level that can enable widespread use. Furthermore, it significantly reduces the development period, using technology, knowledge and experience gained through many years of FCEV development.

ALSO READ:

Denso’s new silicon carbide power semiconductors used in Toyota Mirai

Toyota Mirai sets Guinness world record with 845-mile zero emission drive

Toyota to supply hydrogen fuel cell modules to European truck company Hyliko

RELATED ARTICLES

Dongfeng Nissan secures 17,215 bookings for N7 electric sedan in first month

Sleek zero-emission sedan attracts new buyers to the brand in China with 70% of orders being first-time Nissan owners.

New sensor tech helps reduce rare earth elements in magnets for EVs

Continental’s e-Motor Rotor Temperature Sensor (eRTS) technology offers more precise alternative to algorithm-based heat...

New ZF thermal management system increases EV range by up to 10 percent

New TherMaS system, which uses propane as a refrigerant delivers cooling and heating capacities of at least 10 kW at out...

10 Mar 2023

10 Mar 2023

6683 Views

6683 Views

Autocar Professional Bureau

Autocar Professional Bureau