New sensor tech helps reduce rare earth elements in magnets for EVs

Continental’s e-Motor Rotor Temperature Sensor (eRTS) technology offers more precise alternative to algorithm-based heat projection in permanent magnet synchronous EV motors. Reduced tolerance from 15deg C to only 3deg C enables more cost-efficient use of rare earth elements and increases potential vehicle performanceContinental has developed a new sensor technology that measures the temperature inside permanently excited synchronous motors in electric vehicles (EVs) directly on the rotor for the first time. The e-Motor Rotor Temperature Sensor (eRTS) delivers significantly more precise measu

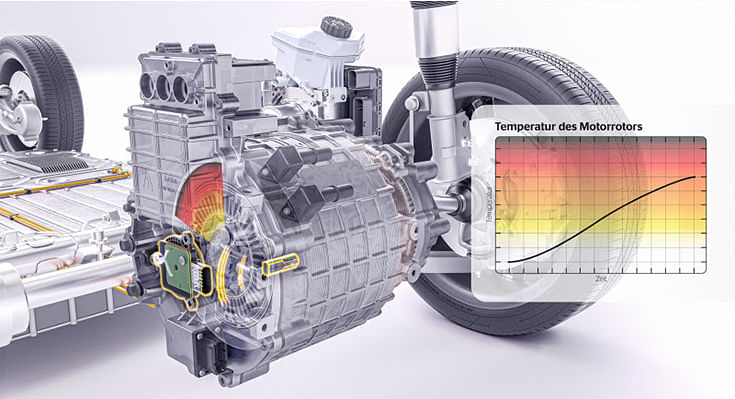

Continental has developed a new sensor technology that measures the temperature inside permanently excited synchronous motors in electric vehicles (EVs) directly on the rotor for the first time.

The e-Motor Rotor Temperature Sensor (eRTS) delivers significantly more precise measurement results than the current software-based temperature simulation – with a tolerance range reduced from 15deg C to just 3deg C. This enables vehicle manufacturers to reduce the amount of rare earth elements used to increase the magnets’ heat resistance and to improve potential motor performance, which also means greater sustainability. The eRTS is one of several sensor technologies for EVs developed by the E-Mobility Sensors (EMS) product centre in Continental Automotive.

“With less resource consumption and lower costs, eRTS sensor technology is advantageous to current solutions,” says Bin Huo, head of the Passive Safety and Sensorics (PSS) segment in Continental Automotive. “This innovation shows that investing resources and focusing expertise in our product centre were the right decision. We will continue to successively expand our EV sensor portfolio.”

eRTS contains two separate components: the wireless mote temperature sensor unit located close to the magnet in the EV motor and the wired transducer element located outside the EV motor. It is connected to the inverter control.

eRTS contains two separate components: the wireless mote temperature sensor unit located close to the magnet in the EV motor and the wired transducer element located outside the EV motor. It is connected to the inverter control.

Higher measuring accuracy helps to reduce use of rare earths

Rotors operate under extreme conditions, for example in temperatures of up to 150deg C. For this reason, monitoring and controlling temperature development in EV motors is crucial. Currently, heat development is not measured directly but calculated based on the information from the stator temperature sensor, phase current measurements and environmental variables. This comes with a tolerance range of up to 15deg C.

The eRTS sensor technology offers a much more precise alternative to algorithm-based temperature projection in permanent magnet synchronous EV motors.

The eRTS sensor technology offers a much more precise alternative to algorithm-based temperature projection in permanent magnet synchronous EV motors.

To protect the magnet from demagnetization due to excessive temperature, expensive rare earth elements are used to cover the entire tolerance range and ensure the magnet is heat-resistant. With greater measuring accuracy reducing the tolerance range to 3deg C, car manufacturers profit from new possibilities and freedom of choice in permanent magnet synchronous EV motor design: a significant portion of costly rare earth materials, which would normally have to exceed the higher tolerance range for safety reasons, can be saved. Another interesting variable is the possibility to improve motor performance by pushing the limits of the tolerance range.

“Our E-Mobility Sensors product center aims to increase efficiency and sustainability in electric vehicles,” says Christoph Busch, who heads the product center. “The eRTS technology is a good example of this: reducing the use of rare earths contributes to a more sustainable supply chain, especially given that the number of EVs is expected to greatly increase in the coming years and decades. In combination with other sensor technologies, such as the e-Motor Rotor Position Sensor, it can even act as a system solution to create synergies that can save car manufacturers money and effort.”

Ultrasound technology for energy supply and communication

eRTS contains two separate components, the mote element and the transducer element. The mote temperature sensor unit measures the temperature directly at the target area, as close as possible to the magnet. The wireless mote draws its energy only from the wired transducer that is connected to the ECU, providing the transducer with its measuring data. The transducer is located outside the EV motor on the chassis. It is connected to the inverter control, transmitting temperature information through a communication interface. Mote and transducer communicate via Piezo ultrasound, which also provides for the energy supply.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

05 Jun 2025

05 Jun 2025

7508 Views

7508 Views

Ajit Dalvi

Ajit Dalvi