New ZF thermal management system increases EV range by up to 10 percent

New TherMaS system, which uses propane as a refrigerant delivers cooling and heating capacities of at least 10 kW at outside temperatures of -25deg C to +35deg C. ZF claims it also saves space, weight and maintenance costs

Highly efficient thermal management systems can extend the range of battery-electric vehicles (BEVs) and plug-in hybrid vehicles (PHEVs) without the need for more expensive drivetrains or larger batteries. With TherMaS, which is now ready for the market, ZF is demonstrating its overall vehicle expertise in this promising development area.

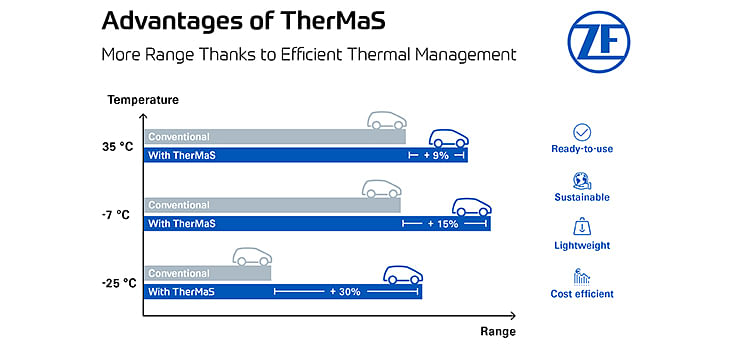

As a highly integrated system, TherMaS is lighter and smaller than comparable variants, yet more efficient and cost-effective. The use of propane as a refrigerant results in significantly better cooling performance, as well as a smaller and lighter system design. In tests, the optimized thermal management and more efficient use of waste heat from the drivetrain increased the electric range in demanding winter operation by up to 10 percent and even up to 30 percent under extreme conditions – setting new benchmarks for climate control functions.

How do you get more range out of an electric vehicle's battery charge? For many, the most obvious solution is to increase the efficiency of the electric motor or to install larger, more expensive batteries. But there are other options. After all, a large proportion of electricity consumption is generated by the heating and cooling requirements of the vehicle interior and the electric drive – depending on the weather and operating conditions. The task of thermal management systems is to manage this.

"The battery of an electric car in particular is very sensitive when it comes to its ideal operating temperature. It feels most comfortable between 15 and 25deg C," explains Dr. Otmar Scharrer, Senior Vice President R&D, Electrified Powertrain Technology, ZF. The ambient temperature therefore has a major influence on the effective range of an electric vehicle. This is because on extremely cold or extremely hot days, the thermal management system is under greater strain, which leads to higher power consumption and can almost halve the available range. "Improving thermal management is therefore of great benefit to both the manufacturer and the driver," says Scharrer. This was the motivation for ZF to develop its own thermal management system, TherMaS, to market maturity.

ZF has extensively tested TherMaS in a demonstration vehicle. There, the system provided up to 10% more electric range in demanding winter operation and even up to 30% more under extreme conditions.

ZF has extensively tested TherMaS in a demonstration vehicle. There, the system provided up to 10% more electric range in demanding winter operation and even up to 30% more under extreme conditions.

Superior performance with less complexity

ZF had already installed and presented a concept study of a central thermal management system for controlling the thermal processes for the drive, battery and interior in a vehicle in 2023. "Since then, we have made significant technological leaps. Thanks to the superior capabilities and easy-to-integrate design, our customers can expect better e-drivetrain performance and a longer electric range without compromising on comfort," summarizes Scharrer.

With cooling and heating capacities of at least 10 kW between -25deg C and +35deg C outside temperature, TherMaS has enough power to keep the battery thermally in the optimum operating range – and with less noise and vibrations than the benchmark. In addition, ZF took a more holistic approach than the alternatives currently available.

The engineers integrated all thermal management functions into a complete, independent subsystem. This included the development of the company's first in-house heat pump. These efforts have paid off: compared to market solutions, TherMaS is simpler and lighter, more efficient and more cost-effective for customers to integrate.

Using propane as a refrigerant

The highlight of TherMaS is a very compact, propane-based heat pump refrigeration circuit that integrates the individual components as required – and customized – according to temperature, heating and cooling requirements. In addition, there are two further, separately controllable cooling circuits in which frost-protected water flows as usual. One is used for the electric motor, the other for the power and charging electronics including the battery.

Because propane cools particularly well, the ZF engineers were able to keep the circuits smaller than with conventional systems while maintaining the same performance. The overall complexity of the system has also been reduced – particularly in the E/E architecture and the control of the water and glycol circuits. A lighter and smaller housing brings additional benefits for manufacturers. The compact design not only saves installation space and assembly time but also helps to reduce heat and cooling losses – because it can be mounted closer to the cabin, which enables short lines. The high degree of integration also reduces the expected maintenance effort and thus increases the cost-benefit ratio for car manufacturers.

Extensively tested and ready for the market

ZF states that it has extensively tested TherMaS in a demonstration vehicle. There, the system provided up to 10 percent more electric range in demanding winter operation and even up to 30 percent more under extreme conditions.

TherMaS was also convincing in other real driving scenarios. The new thermal management system from ZF will be available in three performance classes to cover a wide range of applications and vehicle platforms. Automotive manufacturers have already signalled great interest and confirmed the high degree of maturity of the prototype, points out the German technology and component developer and supplier.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

04 Jun 2025

04 Jun 2025

8000 Views

8000 Views

Ajit Dalvi

Ajit Dalvi