Michelin, Canada’s Pyrowave to industrialise innovative plastic waste recycling technology

The scientific breakthrough behind Pyrowave technology helps recycle plastics using microwaves.

Canada-based Pyrowave has announced a joint development agreement with American-tyre major Michelin Group. The partners says through the Pyrowave‑developed technology, it is possible to generate recycled styrene from plastics found in packaging, insulation panels and/or household appliances.

This recycled styrene is an important monomer – (a molecule with natural or synthetic origins. By successive sequences with identical or different molecules, it generates a polymer structure) – it is used in the production of polystyrene and synthetic rubber for tyres and a large number of consumer products.

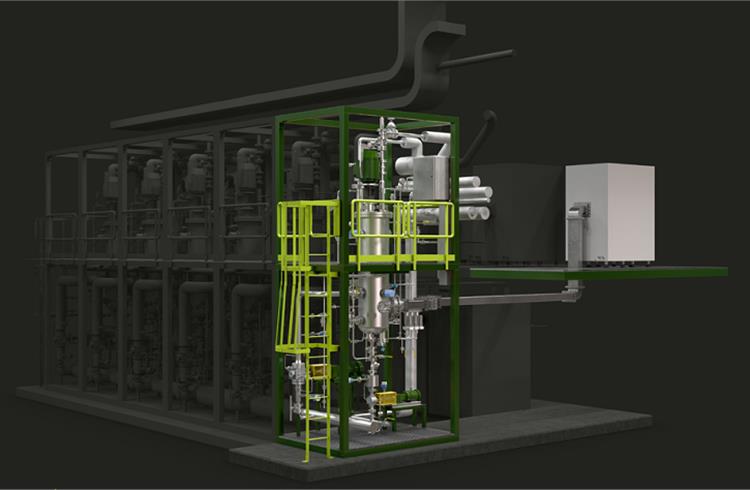

The scientific breakthrough behind Pyrowave technology helps recycle plastics using microwaves. Unlike current thermal processes, the unique technology enables the recycling of plastic waste into high-quality raw materials using electricity – the energy form currently providing the highest decarbonation potential. It also provides higher yields, while being more accurate than conventional technologies, to replace virgin raw materials from oil and gas.

The joint development agreement between Pyrowave and Michelin will result in the implementation of new value chains in the circular plastics economy. Redesigning new packaging or manufacturing new products from recycled plastics in the automotive, electronics or tyre sectors will become possible.

Industrial demonstration by 2023

The partners will work together in the coming months to fast‑track the industrialisation of Pyrowave technology with a view to a certification and commercial roll-out in international markets. The joint development agreement, which will ultimately account for an investment of more than €20 million (Rs 165 crore), will combine Pyrowave's expertise with Michelin's industrial know-how.

In order to fast‑track the validation of the technology and the certification of its products, Michelin's technical teams will work with their Pyrowave's counterparts to develop an industrial demonstrator, funded and operated by Michelin, by 2023. The technology will meet the highest standards in place within the Group in terms of safety, operation and performance.

After a year of evaluation, Michelin says it has been able to see the process in operation and test samples of recycled styrene in the composition of its tyres. This polymer regeneration process is fully in line with Michelin Group's strategic vision and its product sustainability objectives.

Sonia Artinian-Fredou, executive VP, Services & Solutions, High Tech Materials at the Michelin Group said: "This partnership is an ultimate illustration of the Group's sustainable strategy. The purpose is to manufacture tyres made of increasingly sustainable materials and to make these technologies available to innovative recycling channels. We believe in the potential of Pyrowave technology and share their vision for a more sustainable future through innovation."

Jocelyn Doucet, co-founder and CEO, Pyrowave said: "Our partnership marks the beginning of the industrialisation phase, drawing on the expertise and technical soundness of the Michelin Group. This strategic partnership reflects the attractiveness and potential of chemical process electrification, both environmentally and commercially, for world-scale players in the chain value. Through this partnership with Michelin, we will be in a position to develop a breakthrough technology with a view to transforming future materials in a sustainable way."

Pyrowave is a leading player in the field of electrification of chemical processes using microwaves with low‑carbon footprint. The company has expertise in the circular economy of plastics and microwave chemical recycling, to enable post-consumer and post-industrial plastics to be restored to new plastics, reinstating these resources to their full value. Its patented high-power microwave catalytic depolymerisation technology platform is the most advanced worldwide and is now at the forefront of the new generation of plastics. In restoring plastics to their molecular state identical to virgin materials, Pyrowave technology enables infinite recycling of plastics and provides a circular economy solution to meet the global challenge of plastic recycling.

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

19 Nov 2020

19 Nov 2020

6004 Views

6004 Views