Universal Robots bullish on India's auto sector and SMEs

The 11-year-old Danish company, with its Indian arm in Bangalore, sees high potential for small robotic applications in India’s fast-evolving automotive manufacturing sector.

Rapidly growing robot-making company Universal Robots is eyeing the evolving manufacturing practices across industries including automotive.

With a focus on increasing productivity and efficiencies on the assembly lines in manufacturing plants that operate 24x7, the company looks to bank upon the next-generation environment of robots and workers working together.

Universal Robots, which was officially founded in 2005 (see company history panel alongside), works towards making robotic technologies accessible to small and medium enterprises (SMEs). It is also the first mover in the small robot space.

Explaining the concept to Autocar Professional, Daniel Friis, CCO, Universal Robots, said: “Our robots are for small and medium businesses and not for large plants with heavy machinery. Conventionally, when you talk robotics, you talk about the automotive industry and large and heavy, complex robotic arms. Of course, our business is going in that direction because that’s where they use the robotics, and they can add another dimension to their activities with our products (small robots). We foresee that roughly one-third of our business in going into the automotive sector including the suppliers around this industry.”

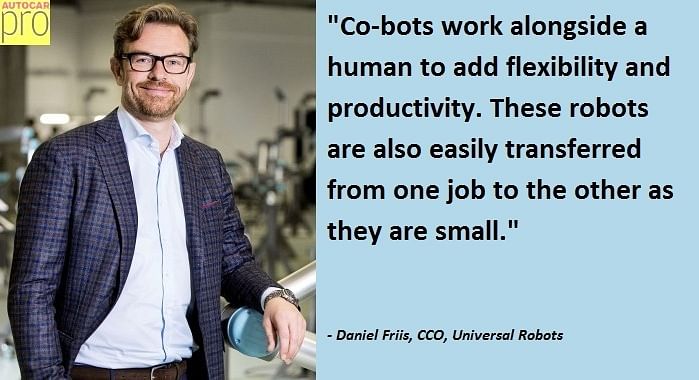

“We do not promote replacing employees with industrial robots. What our products do is very different to that notion. Our robots can be used as tools that can work collaboratively with the manpower in the small and medium enterprises. They are easy to use and easy to program. One of the biggest advantages is that there is no need for safety measures around these small robots, unlike the large ones. So it’s essentially a robot that works alongside a human to add flexibility and productivity. These robots can also be easily transferred from one job to the other as they are small."

"It is a huge opportunity for small businesses to change the way they work and get more efficiency out of their production. These products can take up boring, laborious tasks while the manpower can move to more complicated and crucial jobs,” Friis added, throwing light on the collaborative nature of robots with a light payload.

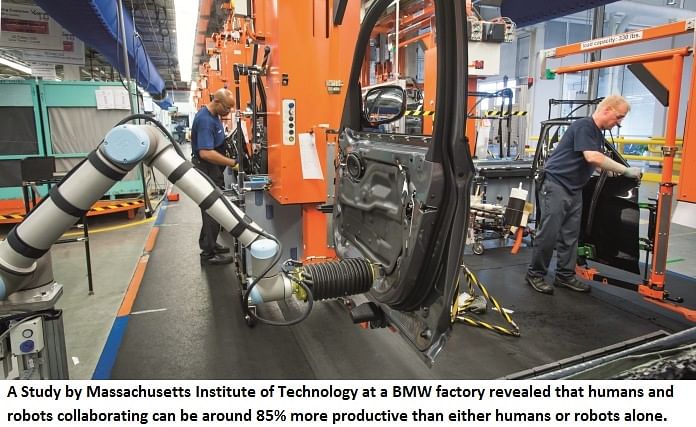

What an MIT Cobot study revealed

According to Pradeep David, general manager, India operations, Universal Robots, in a human-machine study conducted by MIT researchers at a BMW factory, it was shown that teams made of humans and robots collaborating efficiently can be around 85 percent more productive than teams made of either humans or robots alone.

Also, the cooperative process reduced human idle time by virtue of its pace-setting ability.

“That’s how the manufacturing of the next generation will look like. We are talking about collaborative robots, which we call co-bots. These are designed ground-up to be extremely light. We can put it on our shoulder and can carry a 5kg payload unit for different jobs. You can plug it into the wall and have it work like just another consumer appliance. Unlike traditional robots, these don’t kill you. The new paradigm is to have a worker and a co-bot work hand-in-hand,” he said.

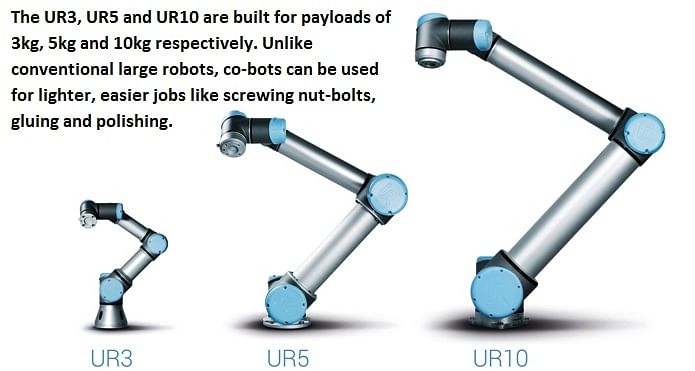

On the operational side within an automotive plant, while large conventional robots are deployed with heavy applications which are not suitable for manual work such as moving chassis units or hot forged parts or welding and painting applications, small robots can be used for lighter, easier jobs including screwing the nut-bolts, gluing, polishing and other tasks. The senior company officials see high potential for their products in the auto ancillary space.

An interesting example here is Lear Corporation, which has optimised just-in-time assembly by introducing the small robotic applications from Universal Robots on its production line. The small, UR5 unit works within the space constraints and helps the company prevent crucial errors.

“The robotic arm is responsible for screwing together automotive seat and rest frames with an end-of-arm screwdriver, completing around 8,500 drilling actions every day. The seats are equipped with a transponder containing individual identification data. As soon as the seat arrives underneath the robot, the transponder is read and the robot tightens several screws on both sides of the seat. If screws are missing on a seat, the robot picks this product out and issues a warning signal, thus preventing faulty seats from continuing on the conveyor belt. The result is an increase in both production speed and product reliability,” quotes an official source.

Rapid regional growth

The company, which first entered the Asian market by establishing a local office in China in 2011, now has a global footprint across all major markets. It is looking to open up nine new offices this year.

“We have done business in India for the past two-and-a-half years. But since we have grown real rapidly, we decided to set up a local office here. But this isn’t the case only for India. We are setting up around nine new offices around the globe, a lot of them in Asia. We have one in Shanghai, we will add one in Shenzhen (China), one in Korea, Japan, Taiwan each and one in Bangalore,” Friis told Autocar Professional.

The company aims to set up branch offices recruiting people for technical support, sales and marketing profiles to further support the network of local partners to boost its regional business units.

“So I need Pradeep to tell me that the way we do business in India is different than the way we do the same in, say, Germany, US, China and other markets. So we will adjust accordingly for maximum impact in the local market. Our model is 100 percent indirect. We will have an office in India, which is going to support the partner network that we are about to build up,” stated Friis.

In June 2016, the company partnered with the Chennai-based specialist distributor of robotics, automation and material handling solutions, Alstrut India.

“This partnership is in line with Universal Robots’ plans to scale up their business and expand their network in India. As they are customer facing and have direct access to the SME manufacturers and also a better understanding of customer requirements, they can facilitate co-bots as tools to manufacturing facility or factory units,” quotes a company release. With that, Universal Robots India’s local partner network included 10 distributors.

The company management is now looking to actively facilitate manufacturing activities across industries in India aligning its vision with the government’s Make-in-India initiative.

HOW UNIVERSAL ROBOTS WAS BORN

In 2003, Universal Robots' three founders, EsbenØstergaard, Kasper Støy and Kristian Kassow, met at the University of Southern Denmark in Odense. Together, they came up with the idea of creating a light robot that is easy to install and program. They saw that heavy, expensive and unwieldy robots dominated robotics and that there was a market for a more user-friendly option.

Universal Robots was officially founded in 2005, with the goal of making robot technology accessible to small and medium-sized enterprises. The establishment of the company was made possible by an investment by Syddansk Innovation.

In 2008, the Danish State Investment Fund was convinced of Universal Robots’ potential and joined the management team and Syddansk Innovation in investing in the company.

In 2009, the first robotic arms were sold by distributors in Denmark and Germany. Universal Robots’ first product was the UR5, a six-jointed articulated arm robot that weighs 18kg, has a lifting capacity of up to 5kg and a working radius of 85cm.

In 2010, Universal Robots expanded its business to cover European markets entirely. In 2011, the company entered the Asian market and set up a local office in China.

In 2012, the company launched UR10, which has a lifting ability of 10kg and a reach of 130cm. The company also established an American subsidiary, based in New York. By this time, it had installed around 1,600 UR robots worldwide.

In 2013, Universal Robots formed a new subsidiary in Shanghai, and also set up a distributor network in South America and Oceania.

In 2014, the company expanded its production plant to 12,000 square metres. The third generation of the lightweight robot arms — UR5 and UR10 — were introduced at Automatica in Munich, Germany. The company also established a subsidiary in Barcelona, Spain. By this time, it installed more than 3,500 UR robots worldwide.

In 2015, the company was acquired by Teradyne, a leading supplier of automated test equipment, for US$ 285 million (Rs 1,800 crore). A new subsidiary was opened in Singapore to cover the Asia-Pacific region. It then went on to launch the UR3, the world’s most flexible, lightweight table-top robot with a payload of 3kg. The UR3's applications span manufacturing industries from medical devices to circuit boards and electronic components.

The company, which currently employs 3,800 people worldwide, continues operations under the same management while its headquarters, R&D, and production facilities remain in Denmark. Universal Robots has three-model co-bot range which includes the UR3, UR5 and UR10, which are built for respective payloads of 3kg, 5kg and 10kg.

The company's unit in India is headquartered in Bangalore and has a fully equipped and robust local technical support team to facilitate adequate training sessions and create awareness about co-bot technology.

Also read:

- Universal Robots sees India as key growth market for its 'co-bots'

- Bajaj Auto uses collaborative robots to enhance productivity

RELATED ARTICLES

Renault India's Quiet Fixer

As the head of Renault India, Francisco Hidalgo Marques faces his biggest challenge yet.

Tesla’s Test

Unlike in other markets, Tesla has taken a long-game approach in India, focusing on creating the infrastructure first.

‘India’s E20 Strategy Is the Template Europe Now Needs’

Mahle CEO Arnd Franz believes India’s flex-fuel shift is proving more resilient and market-aligned than the EU’s all-ele...

By Amit Panday

By Amit Panday

16 Aug 2016

16 Aug 2016

12867 Views

12867 Views