Bajaj Auto uses collaborative robots to enhance productivity

Bajaj Auto has installed close to 120 co-bots in its three plants where perform tasks such as deburring, decal applications, vision applications, machine tending, welding, sealant applications, and bolt tightening.

Bajaj Auto, India’s leading motorcycle maker, has teamed up with Danish company, Universal Robots (UR) to drive operational efficiencies across the Chakan (Pune), Waluj (Aurangabad) and Pantnagar (Uttarakhand) plants.

The Pune-based company has installed close to 120 robotic arms, which are termed collaborative robots or co-bots by Universal Robots, across its three plants. These co-bots are deployed to perform tasks such as deburring, decal applications, vision applications, machine tending, welding, sealant applications and bolt tightening among others.

In a joint demonstration with Bajaj Auto, Universal Robots highlighted the utility of its co-bots in a two-wheeler manufacturing plant.

Pradeep David, general manager, India operations, Universal Robots, told Autocar Professional that these co-bots, with their 3kg to 10kg payload capabilities, are suitable for two-wheeler manufacturing operations and their component suppliers, thanks to the small and medium size and weight of the assembly parts.

“Bajaj Auto was a visionary in terms of realising the utility of our co-bots on their shopfloor operations to enhance and drive their productivity. They were the first automotive company to implement the concept of collaborative robots on their assembly lines in India,” said David.

The two companies' links go back to 2010 when Bajaj Auto had first contacted Universal Robots. “We were looking for multi-modelling and automation in critical tasks such as welding, painting, assembly and skilled operations like fettling, decal and others when we spotted Universal Robots. A two-wheeler assembly line has a typical pitch dimension of one metre, which meant that we needed compact and lightweight robots that should fit into the given setup. We first procured 30 co-bots to study their impact in terms of productivity and output,” disclosed Vikas Sawhney, general manager, engineering (robotics & automation), Bajaj Auto.

Later, to keep costs in check, Bajaj Auto, following an agreement with Universal Robots, ordered more co-bots (in knocked down form) and began assembling them at its Akurdi facility. “We began assembling these co-bots around November 2011 at Akurdi with help from Universal Robots. This helped us bring down the costs of these industrial robotic arms (including the software and hardware setup) by 35-40 percent,” said Sawhney.

According to David, the 3kg to 10kg payload co-bots range anywhere between Rs 12 lakh to 20 lakh per unit including their entire setup.

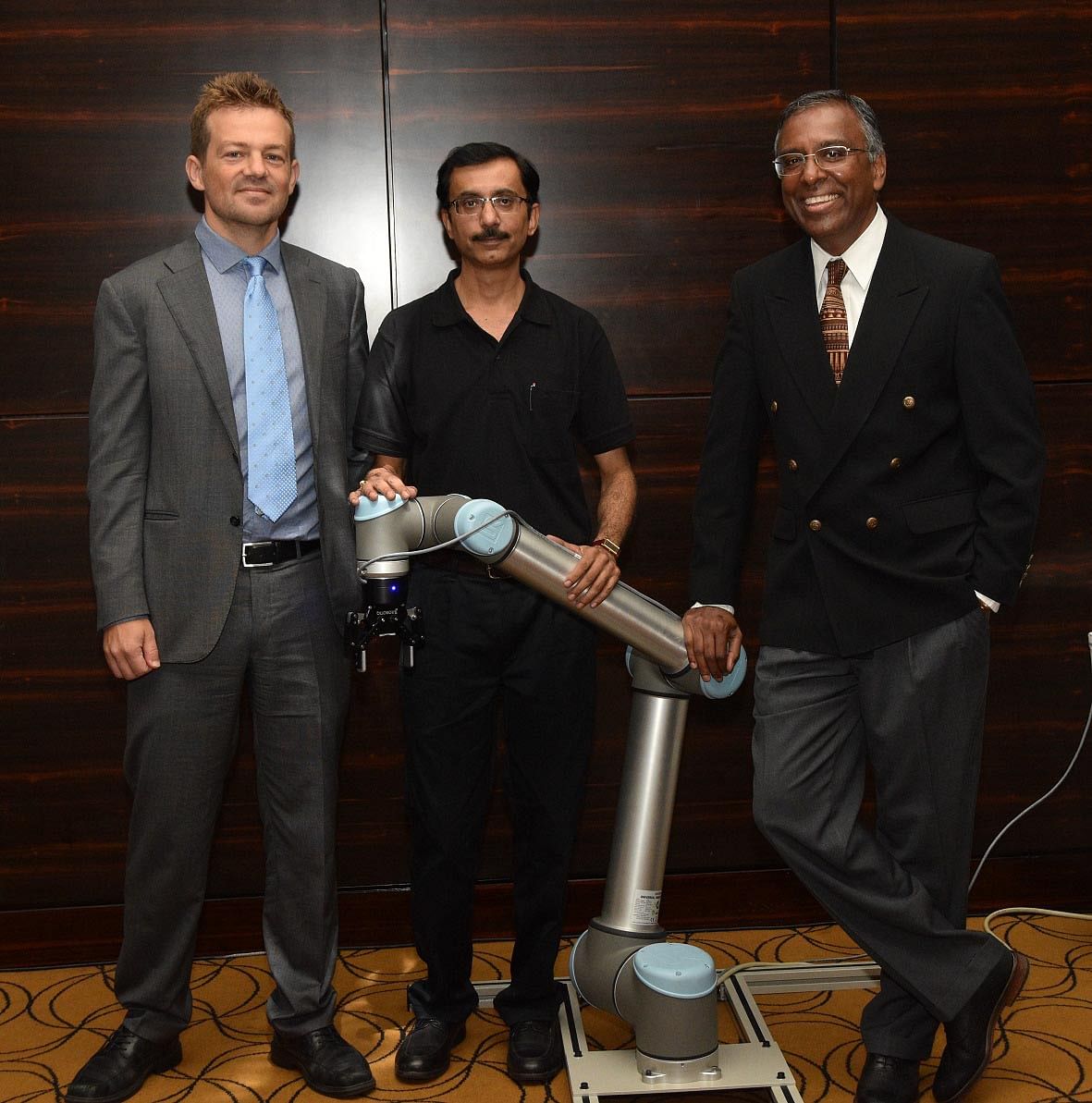

L-R: Dr Esben H. Østergaard, founder and CTO of Universal Robots with Vikas Sawhney, GM - Engineering (Robotics and Automation), Bajaj Auto, and Pradeep David, GM, Universal Robots India.

Helping augment productivity

Crediting overall automation including UR’s co-bots, Sawhney claims that personnel productivity at Bajaj Auto over the past year has grown from 507 vehicles per person per year (V/P/Y) to 804 vehicles per person per year, which is a 58.5 percent increase YoY.

Interestingly, all UR co-bots that Bajaj Auto assembles and has installed so far are of 5kg payload category. The company (BAL) has also given access to these co-bots to some of its key suppliers to improve the processes at the suppliers end too.

Commenting on this example, Esben Ostergaard, founder and CTO, Universal Robots said: “Our co-bots were chosen by Bajaj Auto for their compactness, safety and cost effectiveness. This is a sustainable and suitable option for companies such as Bajaj Auto were employees now possess the right tools to carry out repetitive tasks with faultless precision. We realise that our co-bots can be used for many more applications than what we had earlier imagined while creating UR years ago.”

The company set up its first official footprint in India in October last year. It has installed more than 200 co-bots in India so far. Besides Bajaj Auto, UR’s automotive customers in India now include TVS Motor Company, Mahindra & Mahindra, Royal Enfield, Valeo, Bosch, John Deere, Sonalika, Bharat Forge, Renault and others.

Recommended:

- Universal Robots sees India as key growth market for its 'co-bots'

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Amit Panday

By Amit Panday

19 Aug 2016

19 Aug 2016

26710 Views

26710 Views

Autocar Professional Bureau

Autocar Professional Bureau