Freudenberg Group targets speedier growth in India

Armed with a varied product range from Freudenberg Filtration, Vibracoustic and Kluber Lubrication India, this well-diversified German supplier is bullish on the Indian market.

Any company which has multiple products catering to different needs is well positioned for growth. Germany’s Freudenberg Group is one of them.

This Tier 1 supplier makes everything from lubricant oil to grease, vibration control components to cabin air filters and has been introducing new products at regular intervals for the Indian automotive sector.

While its global revenues from the auto sector hover around 26 percent, in India they have touched 40 percent. What’s helping the company is the growing awareness of prospective car buyers about safety, emission and quality norms and the government’s stricter regulations which has increased demand for some of Freudenberg’s special products. For instance, its cabin air filter is one product which is sought after by almost all carmakers in India.

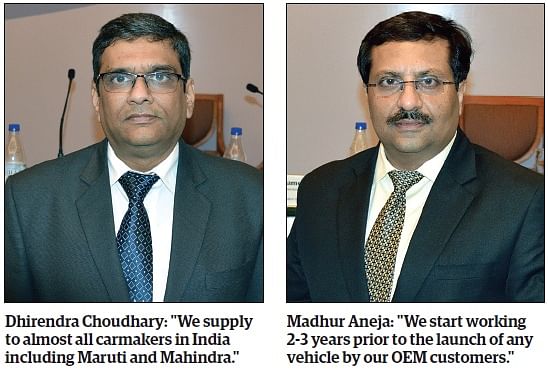

Talking to Autocar Professional, Dhirendra Choudhary, MD and CEO, Freudenberg Filtration, says, “When highly polluted air enters a car through the air-conditioner, it also brings micro dust with it and circulates inside the car for a long time, harming the respiratory system. Without cabin air filters, dust particles as well as unpleasant odours reach the interior of the vehicle directly.”

In vehicles without a cabin air filter, concentration levels may be as much as six times higher than values at the roadside. Besides allergic reactions, they can also lead to breathing tract diseases, cardiovascular problems and asthma.

The Pune-based Freudenberg Filtration makes filters for both automotive and industrial purposes. In the past five years, the sale of cabin air filters has increased manifold. From a level of 150,000 units in 2011, production is likely to touch 3.6 million units this year, say Chaudhary.

At present, around 70 percent of cars manufactured in India are fitted with cabin air filters and 60 percent of them are supplied by Freudenberg. “For each car, we produce different types of filters. We supply to almost all carmakers in India including Maruti, Skoda, Ford and Mahindra,” says Chaudhary.

Keeping engine vibration at bay

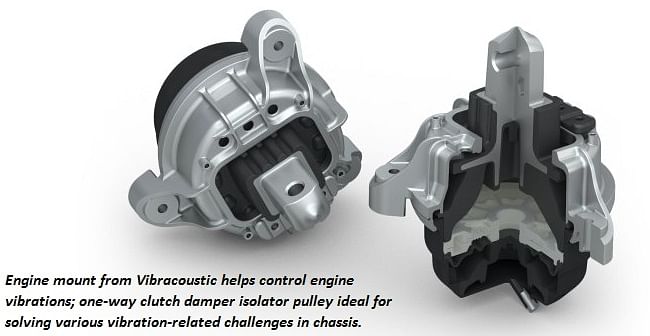

Another Freudenberg division, Vibracoustic makes automotive anti-vibration and noise control systems for the domestic and overseas markets. Modern engines are designed to consume less fuel. This goal can be achieved with smaller, higher-charged engines. However, many of these efficiency drives lead to high vibration levels.

To ensure maximum interior comfort, vibrations must be isolated and road excitations damped as effectively as possible. Powertrain mounts developed and manufactured by Vibracoustic are used with engines or gearboxes in order to achieve this. They consist of an engine or gearbox support arm, an isolation element, and a body-side connecting element. The spring that dampens vibrations and supports the drive torques and isolates noise during start-up is most important. While driving, it prevents booming noises and load change shocks. Vibrations of the body and drive are improved by a hydraulic damping system. With 50 million powertrain mounts built each year, Vibracoustic is the global market leader.

Sharing details, Madhur Aneja, president - Region India, Vibracoustic, says that Vibracoustic in India has been manufacturing anti-vibration systems for both passenger cars and commercial vehicles at its plants in Mohali, near Chandigarh, and in Noida.

Anti-vibration products prevent noise and vibration from being transmitted and the company’s engine mount helps absorb engine vibration. Similarly, the chassis plays a key role in driving comfort, safety and dynamics. It has to transfer power to the road at any time, support and cushion the vehicle as well as to keep it on track and bring it to a safe stop. Precisely tuned suspension springs and chassis mounts from Vibracoustic isolate and reduce unwanted noise and vibrations.

“A majority of our products are made out of rubber and metal. We start working 2-3 years prior to the launch of any vehicle by our OEM customers and design the product accordingly,” Aneja adds.

In India, its clientele includes Maruti Suzuki, Ashok Leyland, Tata Motors, Mahindra, Honda, Hyundai, Daimler, IVECO, General Motors, Volvo, Nissan, Mercedes-Benz and Audi. On the export front, its products are shipped to the US, Europe and China. Around 35 of its Indian revenue comes from exports and its major overseas OEM customers include Volkswagen, GM and Ford. Soon the company will be supplying its anti-vibration systems to Jaguar Land Rover in the UK too, says Aneja.

Lube products

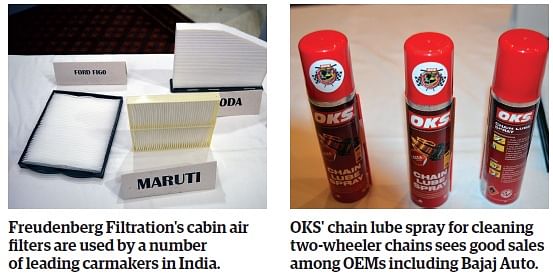

In 2015, Freudenberg invested Rs 290 crore in India, the majority in expanding its production and R&D centre at Kluber Lubrication India in Mysore, which makes specialty lubricating oils, greases, pastes, aerosols and release agents under the Chem-Trend, OKS and Klüber brands.

According to Viju Parameshwar, president, Kluber Lubrication India, the specialty chemical division contributes Rs 300 crore of Freudenberg’s total revenues with around 35 percent of it coming from the auto. The OKS chain lube spray is one of the company's fast-selling aftermarket products. Earlier garage mechanics cleaned two-wheeler chains with used oil. Now the chain lube spray from OKS is the product of choice of several OEMs including Bajaj Auto, for their dealers.

INTERVIEW: Dr Jorg Matthias Grossmann, MD & CFO, Freudenberg India

RELATED ARTICLES

Beyond Cars: VinFast's Full-spectrum EV Push in India

With $2 billion committed, VinFast is constructing an integrated play spanning cars, scooters, buses, ride-hailing and c...

A Breather for Hero

A combination of policy tailwinds, new products and Honda’s cautious approach on EVs put a stop to the constant encroach...

Renault India's Quiet Fixer

As the head of Renault India, Francisco Hidalgo Marques faces his biggest challenge yet.

By Jaishankar Jayaramiah

By Jaishankar Jayaramiah

13 Jul 2016

13 Jul 2016

11686 Views

11686 Views