ACMA-McKinsey study shows the way forward for India’s auto component industry

To achieve the ambitious AMP 2026 targets, India's auto component industry will have to focus on quality and innovation more than ever before and to graduate from being a ‘build to print’ to one that is ‘art to part.’

At its 56th Annual Session and National Conference in Delhi today, ACMA released a detailed study on the Indian auto component industry.

ACMA mandated global management consulting agency McKinsey & Co to conduct a study of the Indian component industry and present a roadmap for the future. The findings of the study highlight the way forward for the auto component industry in India.

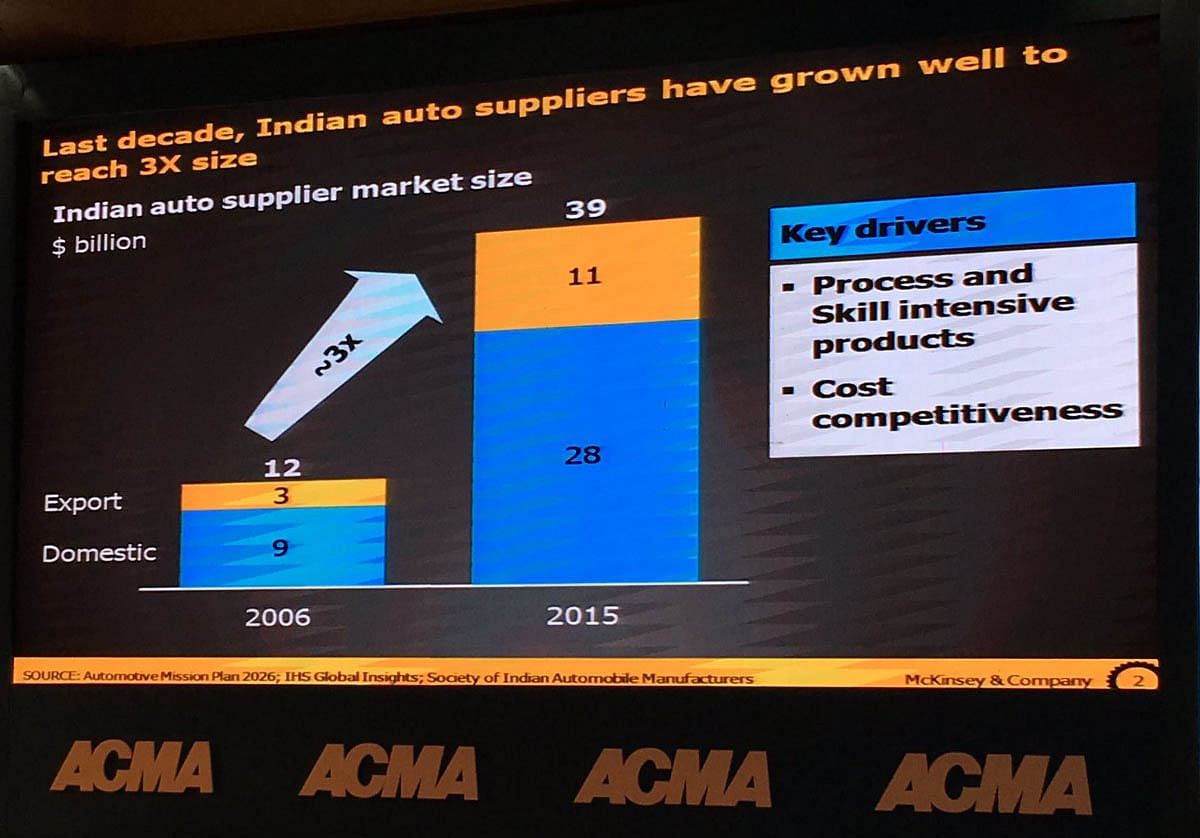

In its presentation, titled ‘Winning with Quality & Innovation’, industry statistics reveal that in 2015-16, the Indian auto component industry’s turnover was Rs 255,600 crore (approximately US$ 39 billion). Exports make up almost 30% of the Indian auto supplier revenue of Rs 70,900 crore (US$ 11 billion). The Automotive Mission Plan 2026 has set ambitious growth aspirations for the Indian auto component industry of Rs 1,211,500 (US$ 200 billion) with exports contributing Rs 462,500 crore (US$ 75 billion) which is 35-40% of its overall output for 2026.

Sharper focus on quality and zero defects needed

To achieve these numbers, Indian auto component manufacturers will be required to develop capabilities for in-house design, harness frugal engineering and create product differentiation through innovation. A move towards product and process innovation along with zero defect quality will be an integral part of this change. It will require industry to focus on quality and innovation more than ever before and to graduate from being a ‘build to print’ to one that is ‘art to part.’

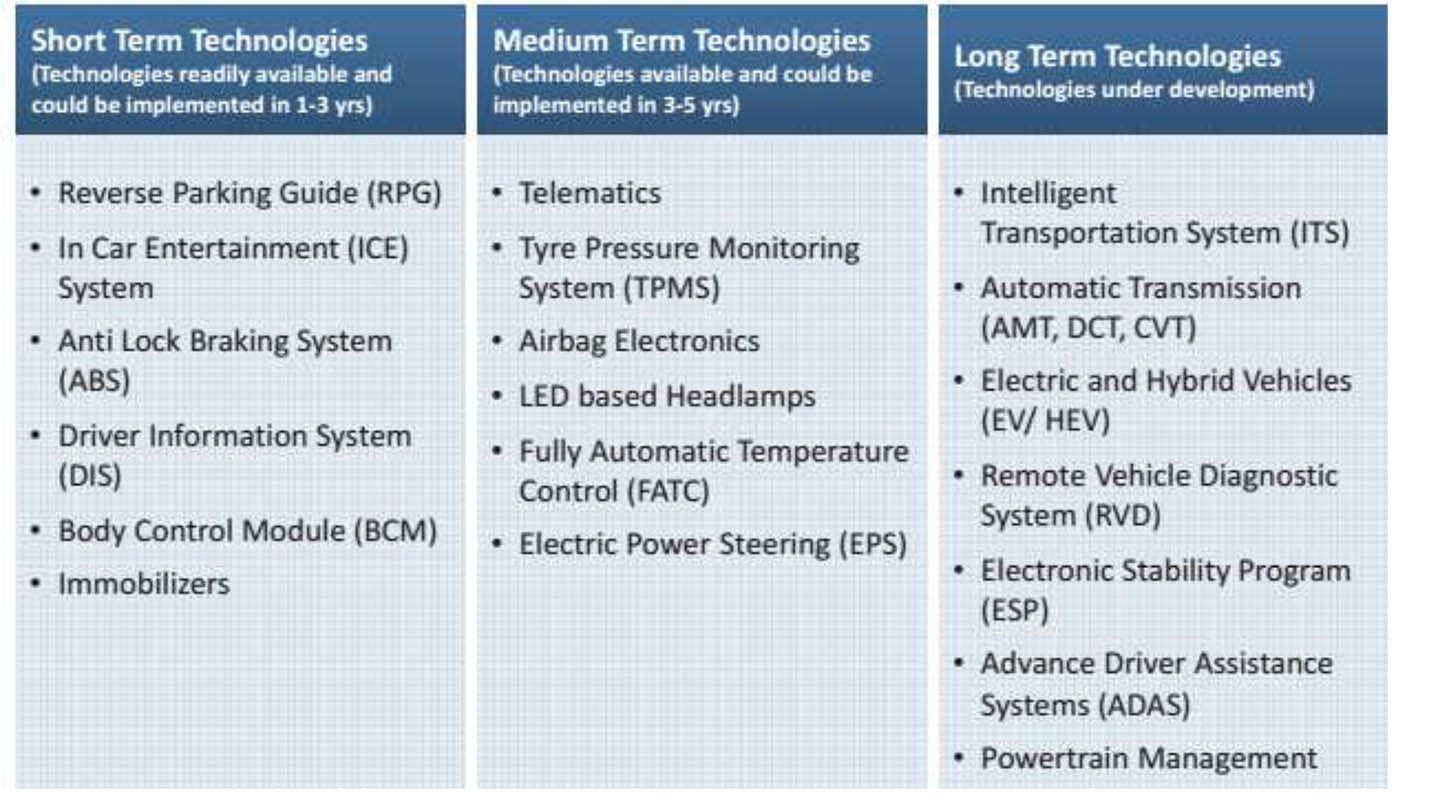

The study says that Indian auto-component manufacturers will have to integrate into global engineering development programmes and increase their R&D spends, focus on engineering and product development to participate in the next round of growth. The type of technologies (illustrative) that need to be adopted to over different periods are:

Quality has direct impact on profitability

While the Indian supplier industry has focused on improving quality over the past few years, it needs to be more proactive and focus on building holistic quality culture through investments, culture and leadership commitment. While impact of poor quality is talked about very often, the upside of good quality is often ignored.

Quality can have a direct impact on profitability. The McKinsey study cites an example. In the year 2000, Ford faced a number of quality problems resulting in recalls of multiple vehicles and a cost of $1 billion. The automaker turned around the situation through a series of quality initiatives (e.g. 6-Sigma, standard processes etc) with strong support from senior leadership improving its JD Power Initial Quality Survey ranking from 25 to 5, while also improving EBITDA margin from 6% to 12% between 2001 to 2010.

Taking disruptive technologies in its stride

New technologies and vehicle concepts have the potential to disrupt the automotive as well as the entire transportation sector. Technologies such as diverse mobility, autonomous driving, electrification and connectivity call for a completely different set of industrial skills and competencies to succeed in a digital world.

Therefore, traditional suppliers will need to develop new capabilities to remain relevant. Thus, innovation is not a choice anymore but is imperative for growth. Without innovation, companies put their businesses at greater risks against competitors and disruptive players.

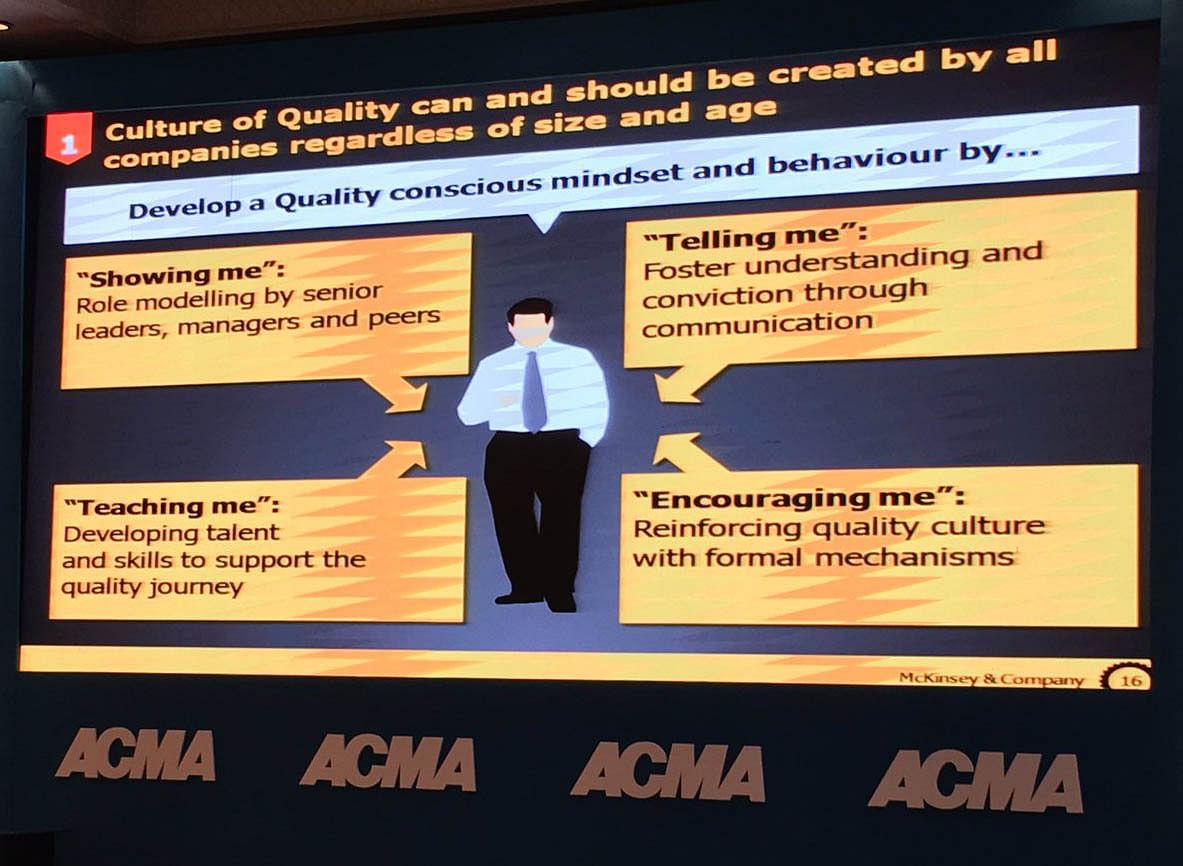

Quality's connect with culture

Culture is the most critical dimension of quality. McKinsey’s research shows that 30% of quality outcomes are linked to culture. Contrary to popular belief, culture of quality can be created in all organisations regardless of age and size. There are 4 steps to create a quality culture in an organisation: by showing (Role modelling by senior leaders, managers and peers), by telling (Fostering understanding and conviction through effective communication), by teaching (Developing talent and skills to support the quality journey) and by encouraging (Reinforcing quality culture with formal mechanisms)

None of these culture shifts are possible without the leadership’s commitment to quality. Leaders play a pivotal role in transforming an organisation’s quality perspective and in entrenching the quality culture necessary for sustainable outcomes by:

- Setting the direction and aspirations for achieving quality excellence

- Demonstrating commitment in quality-focused decision e.g., capital investment, supplier selection prioritising quality over cost

- Creating and sharing inspirational change stories

- Building a strong talent pool and allocate top talent to quality functions

- Making quality top of your agenda and holding every function accountable

Also read: Indian OEMs say good connect with suppliers key to achieving high-quality products

Leaders need to step up to this challenge and adopt a structured approach to the creation of a truly effective quality culture. Over time, this quality-driven approach can help organisations deliver high-quality outcomes consistently and successfully and earn an enviable reputation for excellence.

Speaking at the ACMA Convention, David Keeling, senior partner, McKinsey & Co, said: "Culture can be measured on 5 key parameters: leadership, awareness, capability, mindset and integrity and governance. Leaders in quality performance are leaders in cost performance."

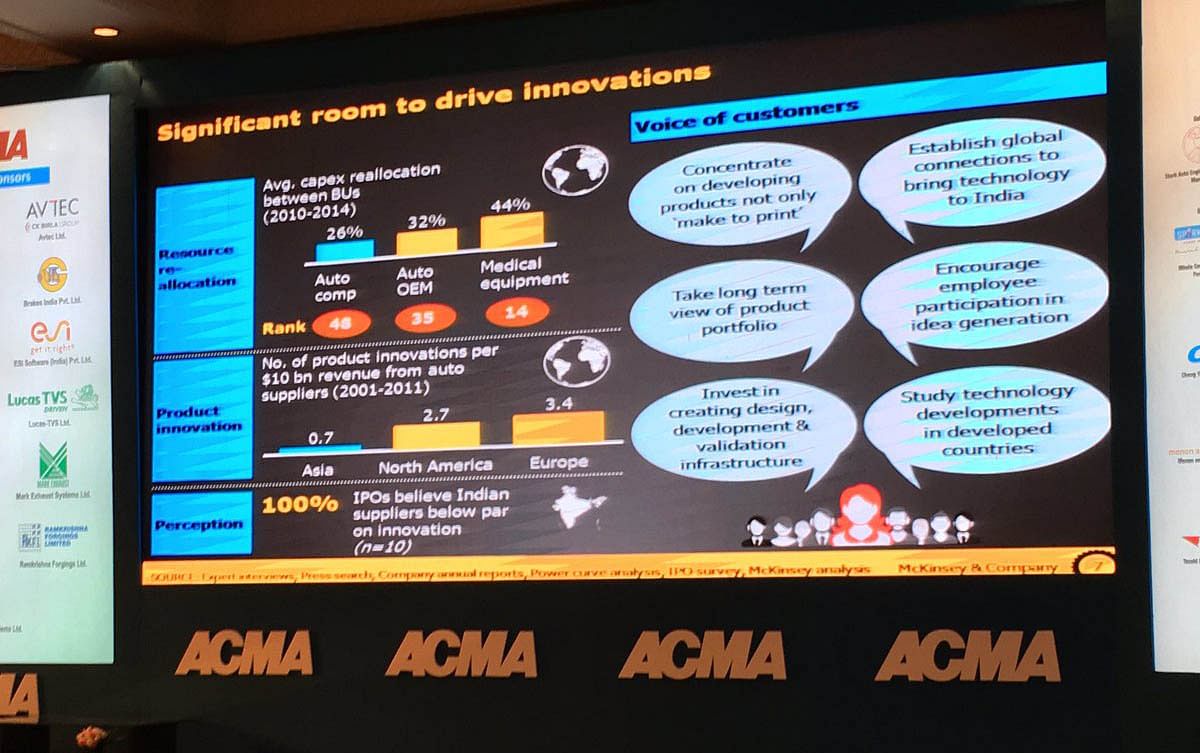

Innovation need not be limited to products

The study notes that innovators in the automotive component supplier industry have grown faster and more profitably compared to others. Historically, the innovations have been driven by European suppliers while Asian suppliers have lagged e.g., between 2001-2011, European players drove more innovations (3.4 innovations per 10 billion euro revenue) compared to North Americans (1.7), and Asians (0.7).

In the changing global marketplace, there is significant room for Indian suppliers to innovate. The innovation need not be limited to products; process, portfolio and business model innovations are equally important and value creating.

While individual companies have to ‘own’ innovation, a conducive eco-system is a critical enabler to ‘drive’ innovations. There have been many successful examples of OEM collaborations with auto suppliers for innovation in developed as well as developing markets. Such partnerships can also be formed within peers (e.g., Goodyear and Michelin jointly developed run-flat technology), universities (e.g, GE’s partnership with IIT-Madras to develop industrial internet-based applications) and startups.

Recommended for you:

- ACMA bullish on growth, targets 8-12% in FY2017

- ACMA convention sees captains of industry urge pursuit of high-quality production and innovation

RELATED ARTICLES

Bajaj Auto launches new Chetak 3503 at Rs 110,000

The Chetak 3503, with a claimed range of 155km, 63kph top speed and a slower charging time than its 35 Series siblings, ...

Hyundai walks the eco talk with biogas plant, material recovery plant in Gurugram

Operational since October 2022, the facility targets sustainable waste management in Gurugram by undertaking scientific ...

Rajiv Bajaj reappointed MD and CEO of Bajaj Auto for five-year term

Bajaj Auto’s Board of Directors has approved the re-appointment of Rajiv Bajaj as the company’s MD and CEO for another f...

By Autocar Professional Bureau

By Autocar Professional Bureau

30 Aug 2016

30 Aug 2016

11037 Views

11037 Views