'If you want to control the level of quality and want to be able to monitor operations, you need to put the processes in place'

India is one of the fast growing markets in terms of the business from the automotive industry. It represents a significant share, which is more than 40 percent, of the revenues in India. I can say that automotive is our number one market in India.

Xavier Silhouette, vice-president - Sales, Transportation & Mobility Industry, Dassault Systèmes, France, is bullish on the manifold opportunities the Indian market is set to provide across the passenger vehicle, two-wheeler, commercial vehicle and component industry as a result of new and upcoming regulations on the emissions and safety front. An interview by Amit Panday.

What, in your view, are the reasons behind the increasing popularity of 3D modeling from vehicle conception to manufacturing processes globally?

3D modeling in vehicle design has been there for many years now. The world around you is three-dimensional and if you want to do virtual twin of your car, allowing it to forecast its behaviour, then you need to have a 3D model.

You need to have a 3D model if you want to do flow simulation, CAE simulation, or in any kind of simulation. 3D modeling is a must if you want to do simulation. I don’t know of any carmaker that does not use 3D modeling today in developing vehicles. This includes carmakers in India. Many of them are using Dassault’s Catia V5, which is widely used by many today in the automotive industry including OEMs and suppliers. We continue to enhance Catia V5 regularly.

Does Dassault Systemes’ 3DExperience mean all software solutions with different core functionalities (ranging from Catia and Solidworks to 3DExcite) come together in one package?

The 3DExperience platform is a business platform, which provides an environment where you can put together different applications and make them run together in an integrated manner. We have an integrated user interface for easy access, a data model that is unique to the different disciplines, and also data that integrates together between the different applications.

Let's say you have to model the B-pillar of a car. You would want to check if this B-pillar is going to resist in the right manner to different effects. You will then have to mesh it, which means you will have to create elementary elements and then check if these elements are performing the right way. If you have to change the B-pillar or its shape slightly, and if you are not working in the integrated environment, then you will have to run back to the initial design stages to re-launch the design elements and make calculations again.

However, with Dassault’s integrated 3D environment, you can perform this function or create new requirements with just a simple press of a button – it will make relative changes through to the initial designs as you modify the elements.

Instead of having a broken cycle wherein you make your changes and then request your CAE expert to re-launch the meshing, you make changes or create new elements seamlessly because it is integrated and immediately.

How big is the automotive business for Dassault in India and globally?

India is one of the fast growing markets in terms of the business from the automotive industry. It represents a significant share, which is more than 40 percent, of the revenues in India. I can say that automotive is our number one market in India.

Globally, the business from the transportation industry contributes to almost one-third of Dassault’s overall revenues. The transportation and mobility vertical covers OEMs, suppliers, trains, motorcycles, the Formula 1 industry and commercial vehicles.

How do you see the opportunities in the manufacturing sector including automotive in India? Peugeot, which is Dassault’s existing global customer, will set up shop in India soon. Do you see extension of your relationship with PSA to India under its Push-to-Pass growth strategy?

Firstly, India is a big market and this is a primary reason why many manufacturers are keen to invest here. They plan to serve the local market, which is growing bigger by the day.

The integral part of this is that when they install a new plant, they are not going to start from scratch. They are going to be reusing some of the processes they have used in their existing plants. They are going to transplant these processes to the local market and then adapt accordingly. So they need to have a system, which allows them to globalise their processes. They need to have a system which can grant good quality levels, the same as everywhere else.

If you want to control the level of quality and want to be able to monitor operations, you need to put the processes in place. Whatever we have done elsewhere we are doing in India. The engineering teams in India are willing to have more quality and enhance their productivity. These factors are mandating the seamless data integration from engineering to manufacturing.

The engineering teams in India are increasingly looking at getting the product development first-time right.

How do you view the legislation-driven opportunities in India?

We have identified challenges in two key areas in the Indian market – safety and emission regulations. They are going to see very strong changes in the industry.

This means that in terms of crash validations, the OEMs will have to invest more. This is good for us because we have ways to help them to do that. Some of the validation solutions that we have should not only help in the core validation process but also help in terms of managing the validation cycles and how you manage the data and traceability.

When it comes to emissions control, all of this is going to put pressure on the OEMs as well as their suppliers to provide new means of reducing emissions, more efficient cars that are also lighter. All this is going to stir up the engineering capabilities. I think that all these developments (new legislative mandates for the automotive industry) are good for industry because they are going to push it to be better in future.

By following new norms, vehicle manufacturers in India will be able to export more in the future. We are seeing these developments in a very positive manner.

Dassault Systemes is understood to be looking at growth in India backed by the commercial vehicle and the two-wheeler segments. Do you agree?

We are seeing growth everywhere. While the two-wheeler market surely provides good opportunities because it is a massive market in India, commercial vehicles too represent a lucrative opportunity for us.

Because of the new incoming norms, we are also seeing growth in the passenger car market in India including the Tier 1 suppliers. Faurecia is a good example of an established Tier 1 supplier of products that will gain traction very soon. There are also a number of local players in India that are quite big in terms of their businesses.

I would like to highlight here that the component suppliers (in India) as a market are equivalent to the OEMs for us. We see that a lot of engineering innovation is being carried out at the suppliers’ end. They are increasingly playing bigger roles in the new product development projects around the world.

On the global R&D front, what are the new areas that are being explored at Dassault Systemes?

We are investing heavily in the development of electric vehicles (EVs). We have some very specific abilities in the development of EVs, thanks to one of our recent acquisitions of a German company named Modelon.

Modelon has brought a lot of abilities in the domain of modeling the behaviour of electric cars including batteries. We are very serious about the capability development for EVs. We are working with all the OEMs in this domain.

We are also investing in autonomous design. You may have heard a lot about autonomous driving but autonomous design is definitely a domain where we are starting to propose solutions and it’s a new frontier.

We started with 3D design wherein we were modeling a part. We then moved to parametric knowledge-based design where we put new rules into the modeling of the part, leading to further evolution of the part. This allows you to be very quick in terms of bringing new changes while modeling the part.

Now we are working on autonomous design, which is putting in place some cobots and some loops of automatic creation of products validating it towards some specifications and extracting very new ways of designing things.

This can be done for general designs as well. You can enrich it with artificial intelligence of how you did designs before. You can enrich your model(s) with the past product developments. Given the integration of the tools you have today, you can really do very exciting things.

What is the contribution of Dassault’s R&D team based in India towards the development of these futuristic projects?

The Indian R&D team comprises over 2,100 engineers. It is the second biggest after the one in France. They play a key role in the development, coding and the testing work. So, yes, they do play a very crucial part in futuristic projects.

What are your immediate priorities going forward?

Firstly, we need to ensure that our customer deployments are successful. I think for us it is key to make sure that our customers are able to get value out of our solutions.

Secondly, we need to address the key challenges of our customers. These challenges can range from new regulations for emission control, safety norms, and autonomous driving features among other issues. All this translates into a smart, safe, and connected system approach to engineering and better design capabilities.

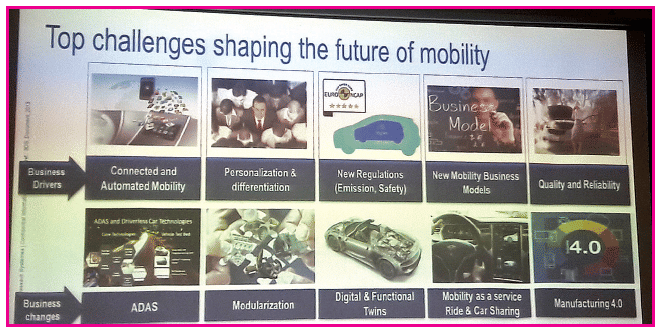

The transportation and mobility industry is facing many challenges today. These challenges are coming from autonomous driving technologies, new car sharing models, emissions control, safety and others.

RELATED ARTICLES

'India Can Become a Major Pillar for Us' - Marquardt Group

Björn Twiehaus, CEO of Marquardt Group, and Vishal Narvekar, the company's India GM, share their outlook on the Indian m...

Luxury Car Market to Slow in 2025: Mercedes-Benz Sees Flattish Numbers

In Jan to March of 2025, the market may witness its slowest growth since COVID-19, and if the weakness continues, the se...

‘We Must Have More Women Leaders in the Auto Sector:’ Anjali Rattan

The chairperson of the New Delhi-headquartered RattanIndia Enterprises believes that with their multi-tasking nature, wo...

15 Jul 2017

15 Jul 2017

10476 Views

10476 Views

Darshan Nakhwa

Darshan Nakhwa

Prerna Lidhoo

Prerna Lidhoo