Universal Robots sees India as key growth market for its 'co-bots'

The Danish manufacturer sees the Indian automotive industry as a ‘sweet spot” and is targeting sales of over 100 collaborative robots.

Denmark’s Universal Robots, which pioneered ‘co-bots’ or collaborative robots which work in sync with humans, foresees good business coming its way from India and, more specifically, the Indian automotive industry.

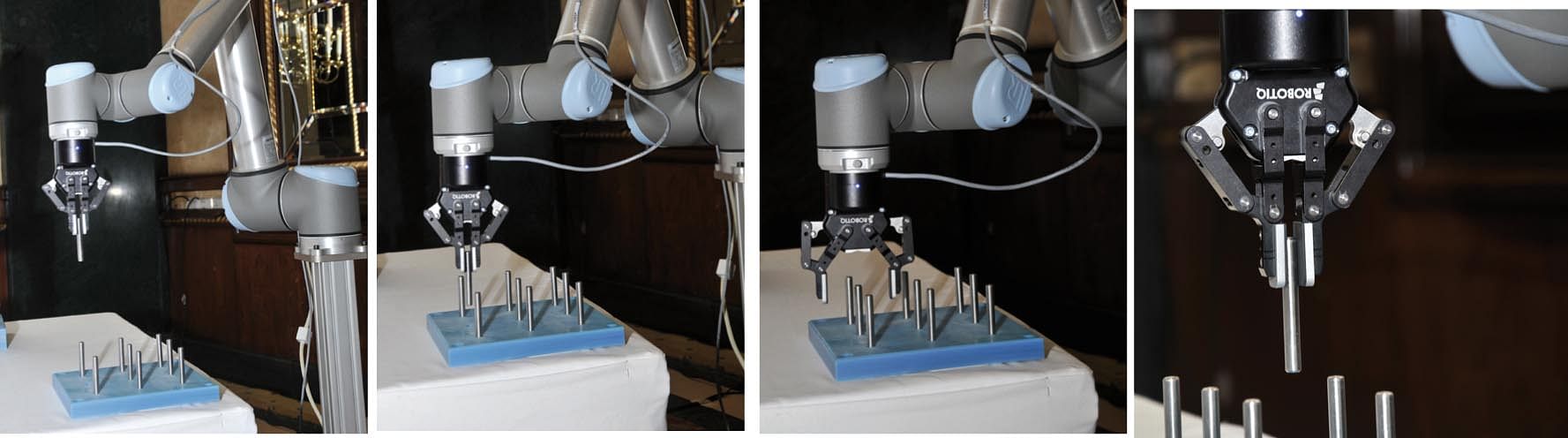

Co-bots are designed to work with humans and assist them in a variety of tasks which help to automate and streamline repetitive and potential unsafe processes, thereby ensuring a safe work environment while increasing productivity and efficiency.

The gains, the company says, can be many. A study by MIT researchers at a BMW manufacturing plant revealed that teams comprising of humans and robots collaborating efficiently can be around 85 percent more productive than teams made of either humans or robots alone. Also, the cooperative process reduced human idle team by virtue of its pace-setting ability.

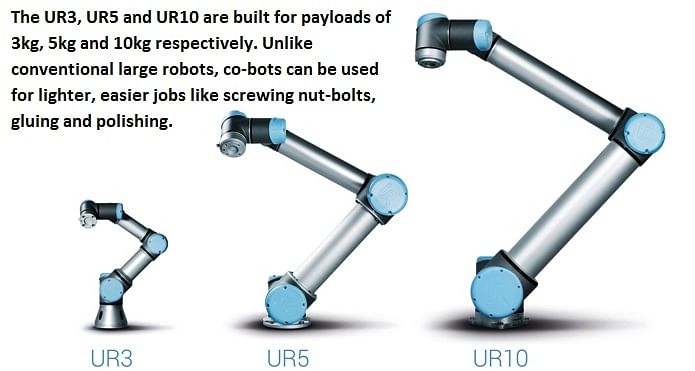

Universal Robots has a three-model co-bot range which comprises the UR3, UR5 and UR10, which are built for payloads of 3kg, 5kg and 10kg respectively. Pricing for the model range in India starts from an estimated Rs 800,000 and goes up to Rs 18-20 lakh.

The ultra-flexible UR3 delivers high-precision accuracy for smaller production environments and is claimed to be ideal for electronics, technology, scientific, pharmaceutical and agricultural facilities. The lightweight UR5 is good for automation of repetitive and dangerous tasks and is meant for low-weight collaborative processes such as picking, placing and testing.

With a working radius of up to 850mm, the UR5 helps put everything within reach, freeing a worker’s time to add value to other stage of production. The UR10 is the company’s largest industrial robot designed for bigger tasks where precision and reliability are of key importance. Heavier-weight collaborative processes such as packaging, palletising, assembly and pick and place are all well suited to the UR10.

Billed as providing the competitive edge

The company says that being lightweight, small and compact, co-bots allow users immense flexibility and can be easily moved around in a production facility. As mounting, setup and programming can be done speedily in less than half a day, Universal Robots says co-bots are “ideal for today’s high-mix, low-volume manufacturing environment or the running of small batch and seasonal productions”.

Importantly, they are safe to work with in close proximity with workers. It may be recollected that in July 2015, a worker at a German car manufacturer died after a robot grabbed him and then crushed him against a metal plate. In India too, in June 2015, a worker at an auto parts manufacturer in North India was killed by a robot. It is understood that the worker was in the process of adjusting a metal sheet being welded by the robot when he was stabbed by one of its arms.

This will not happen with the TUV-approved co-bots, says Universal Robots. The co-bots, which are compliant with the ISO standard for collaborative robots (TS 15066), will stop automatically when subjected to a resisting force of at least 50 Newton.

Fast payback period

Esben Ostergaard: "Our robot arms are advanced tools that can be used by all levels of production staff to help increase productivity, quality and market competitiveness."

Speaking at a media meet in Mumbai today, Esben Ostergaard, chief technology officer, Universal Robots, said: “Collaborative robotic technology can be used to benefit all aspects of task-based businesses irrespective of their size. Our robot arms are advanced tools that can be used by all levels of production staff to help increase productivity, quality and market competitiveness. They help ease out processes in task-driven industries like manufacturing and assembly.”

Pradeep S David, general manager, Universal Robots (India), commented: “Our three different collaborative robots are easily integrated into existing production environments. With six articulation points and a wide scope of flexibility, the cobot arms are designed to mimic the range of motion of a human arm. The nominal investment cost is quickly recovered as our robotic arms have an average payback period of just six months. The need for advanced robotics is required for accessibility to anybody who wants to increase productivity while maintaining high safety standards.”

Pradeep S David: "With 6 articulation points and a wide scope of flexibility, the cobot arms are designed to mimic the range of motion of a human arm."

200 cobots sold in India since 2010, Bajaj Auto main buyer

Universal Robots has, since the past five years, sold around 200 co-bots in India with around 125 of them operational at Bajaj Auto’s Chakan and other plants. This year, the company is targeting sales of 100 co-bots in the Indian market, which it believes offers good potential for growth, particularly at two-wheeler manufacturers and small and medium enterprises (SMEs) which manufacture auto components and also electronic parts.

Two-wheeler major Bajaj Auto, which employed a co-bot first in 2010, uses co-bots for material handling, decal application and some other processes. Interestingly, one of the production lines is manned by 50 percent women who say they find working with co-bots “a happy experience’. Aakash Prabhakar of the Robotics Department at Bajaj Auto says, “The physically challenging part has been taken over by co-bots.”

According to Universal Robots (India) Pradeep David, “The ease of use of co-bots is unparalleled. We feel this product has an incredible fit in the Indian market. They are not meant to fully replace labour but collaborate with workers.”

"Co-bots are a huge paradigm shift and they are designed from grounds-up to be safe," he added.

Europe and China continue to be Universal Robots' main growth markets. Demand in China, which saw sales of 75,000 co-bots, is set to double by the year 2018.

While it is still early days yet for the company in India, it is aggressively driving a co-bot awareness drive and is aiming for increased sales in the Indian automotive industry, at both OEMs and SMEs.

The company's unit in India is headquartered in Bangalore and has a fully equipped and robust local technical support team to facilitate adequate training sessions on co-bot technology.

You may like:

- Why Universal Robots is bullish on India's auto sector and SMEs

- Bajaj Auto uses collaborative robots to enhance productivity

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

17 Aug 2016

17 Aug 2016

18895 Views

18895 Views