Toshiba’s new SCiBTM battery promises 320km vehicle range on 6-min charge

Toshiba's new SCiBTM battery delivers 320km range with just six-minutes of charging time, promises new-generation of EVs to benefit from the development.

Toshiba Corporation has been working on its ‘SCiBTM’ lithium-ion battery since 2008, termed by it as a safe, long-life, fast charging battery. The battery has been constantly refined and improved to keep up with real-world needs. The company recently announced that the new generation of SCiBTM can deliver driving range of 320km for EVs in just a six-minute charge.

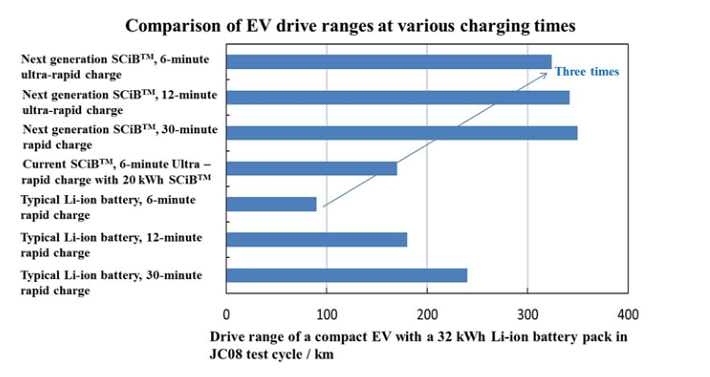

The new generation of SCiBTM uses new anode material, titanium niobium oxide that achieves double the capacity of the anode of current lithium-ion batteries. This offers high- energy density for the ultra-rapid recharging required in automotive applications, providing compact electric vehicle (EV) with a drive range of around 320km after only six minutes of ultra-rapid recharging—three times the distance possible with current lithium-ion batteries.

The new battery uses titanium niobium oxide anode material developed by Toshiba that doubles the lithium storage capacity in terms of volume of the graphite-based anodes generally used in lithium-ion batteries. This also helps in offering higher energy density and ultra-rapid recharging characteristics, and its titanium niobium oxide anode is less likely to experience lithium metal deposition during ultra-rapid recharging or recharging in cold conditions—a cause of battery degradation and internal short circuiting.

Toshiba’s current SCiBTM is used in vehicles and industrial and infrastructure applications, including automobiles, buses, railroad cars, elevators and power plants. Building on this heritage, it has developed new proprietary method for synthesising and disarranging crystals of titanium niobium oxide and storing lithium ions more efficiently in the crystal structure.

“We are very excited by the potential of the new titanium niobium oxide anode and the next-generation SCiBTM. Rather than an incremental improvement, this is a game changing advance that will make a significant difference to the range and performance of EV. We will continue to improve the battery’s performance and aim to put the next-generation SCiBTM into practical application in fiscal year 2019,” said Dr. Osamu Hori, director, Corporate Research & Development Centre, Toshiba.

Rigorous testing of a 50Ah prototype of the new battery has confirmed that it retains the long life cycle, low-temperature operation, excellent safety and rapid recharging characteristics of the current SCiBTM. The energy density by volume of battery is twice that of the current SCiBTM. The next-generation SCiBTM maintains over 90 percent of its initial capacity after being put through 5,000 charge/discharge cycles, and ultra-rapid recharging can be done in cold conditions, with temperatures as low as minus 10°C, in only ten minutes.

Suzuki too gains

In a move that could benefit Maruti-Suzuki India (MSIL) the country’s largest passenger vehicle manufacturer in terms of market share, accelerate its EV plans. Earlier this year, Suzuki Motor Corporation, Toshiba Corporation and Denso Corporation had laid foundation stone for the country’s first lithium-ion battery manufacturing plant.

The manufacturing plant is being set up with an investment totalling $180 million (Rs 1,137 crore) between Toshiba, Denso and Suzuki slated to be ready by 2020. The manufacturing operation will utilise cell modules from Toshiba, while Denso will contribute its expertise by sharing the technology platform. The battery joint venture sees the equity stake split between Suzuki (50%), Toshiba (40%) and Denso (10%). Suzuki Motor Corporation, which is the main driver for the JV, will be aiming to drive home the advantage of manufacturing lithium-ion batteries in its key global market – India – where the government is keen there is greater adoption of electric vehicles (EVs).

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

25 Oct 2017

25 Oct 2017

7393 Views

7393 Views

Autocar Professional Bureau

Autocar Professional Bureau