New ZF SELECT e-drive platform gives EV makers a choice in 100 to 300 kW range

Modular e-drive platform optimally matches 800-volt overall system and components such as the electric motor and power electronics, enables high variance of electric drives to cover current market requirements as well as shorter development times.

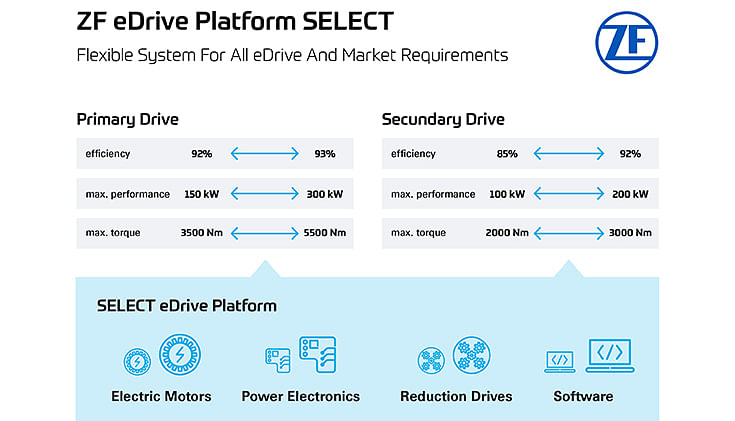

German technology company and supplier ZF chose its annual Tech Day 2025 to announce and reveal an array of innovations, particularly targeted at electric vehicles. With its new SELECT e-drive platform, ZF is positioning itself as the technology leader for all-electric passenger car drives in the 100 to 300 kW power range. With SELECT, ZF states that it “has redeveloped and harmonized an attractive and highly variable overall system as well as the underlying components.”

How the concept works

A newly developed electric drive based on the SELECT platform beats current series production technology in terms of efficiency, power density and other parameters.

In addition to innovations at system and component level, ZF has also designed all components of the SELECT platform in such a way that they are easier to industrialize. They are geared towards automated production methods and multi-sourcing concepts to be able to react appropriately to volatile demand and scale quickly.

Innovation vehicle EVselect, which can vary between different drive configurations while driving.

Innovation vehicle EVselect, which can vary between different drive configurations while driving.

With the SELECT platform, ZF is leveraging its decades of experience in passenger car e-drives – and its in-depth knowledge of the international automotive business. "The pace of innovation in many e-drive components is enormous. Our customers want to have the latest technology available quickly – and with limited integration effort," explains Dr. Otmar Scharrer, Senior Vice-President R&D, Electrified Powertrain Technology, ZF.

"This is exactly where we come in with our SELECT platform: the overall system and components are perfectly matched to each other – at the same time, the components are interchangeable depending on requirements. We will develop future innovations for series production in such a way that they can be easily integrated into the SELECT platform." Clearly defined interfaces within the SELECT platform will also significantly reduce the development time of future electric drives.

Flexible and innovative, yet faster to develop and scalable: ZF SELECT platform is the technological basis for the technology group's future e-drives. Electric drive developed on the basis of the SELECT platform e-drive outperforms a current series solution.

Flexible and innovative, yet faster to develop and scalable: ZF SELECT platform is the technological basis for the technology group's future e-drives. Electric drive developed on the basis of the SELECT platform e-drive outperforms a current series solution.

Modular componentry at work

The SELECT platform consists of several component modules that make innovative technology available and at the same time ensure the high variability of the overall system. These include:

em:SELECT for all types of e-machine technologies. This includes both the tried-and-tested PSM (permanently excited synchronous machines) and ASM (asynchronous machines) and extends to new developments such as the award-winning and sustainable ZF innovation I2SM, a separately excited electric machine that is on a par with a PSM in terms of performance data;

in:SELECT for inverter technology, which is characterized by maximum power density and extremely high efficiency in 800 volt architectures;

co:SELECT for state-of-the-art converters, which are a key component for bidirectional charging – and thus underpin the increasing importance of e-vehicles for the energy transition;

rd:SELECT for reduction gears in parallel-axis and coaxial design, essential for high torque density and thus for very efficient energy use when high-speed motor concepts are required;

sw:SELECT for a software library that covers many basic functions and makes attractive connected driving functions possible.

"SELECT allows us to strike a balance between a high degree of individualization and flexibility, while at the same time speeding up development times for a quick market launch," adds Scharrer.

Platform brings new ZF benchmark

The strong performance of ZF’s SELECT modular system is evident in a newly developed e-drive focused on efficiency: a coaxial primary drive with a PSM delivering 300 kW of power and 5,500 Nm of torque.

At speeds above 100kph, it reduces losses by more than 25 percent – even compared to an already very efficient series solution. In almost all relevant parameters – from installation space and weight to costs – developers achieve better values with the SELECT platform. In addition, the new ZF development can achieve a continuous performance of 60 percent – also a value above the current industry standard.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

04 Jun 2025

04 Jun 2025

26561 Views

26561 Views

Autocar Professional Bureau

Autocar Professional Bureau