‘India is a key part of our global engineering footprint’: SKF Group global CTO

Annika Ölme, Chief Technology Officer of the Swedish and global bearings major, affirms India’s strong role in technology development as well as strengthening the SKF Group’s regional competencies in the sub-continent and South-East Asia.

Swedish bearings manufacturing major SKF Group, a leading Tier-1 player across industries such as automotive and aerospace, is witnessing a heightened level of developmental work originating out of India. Its Global Technical Centre India (GTCI), located in Bengaluru, is conducting advanced engineering and product adaptation activities for local and global markets. The GTCI is also intensifying its collaboration with the Group’s other technical centres around the world.

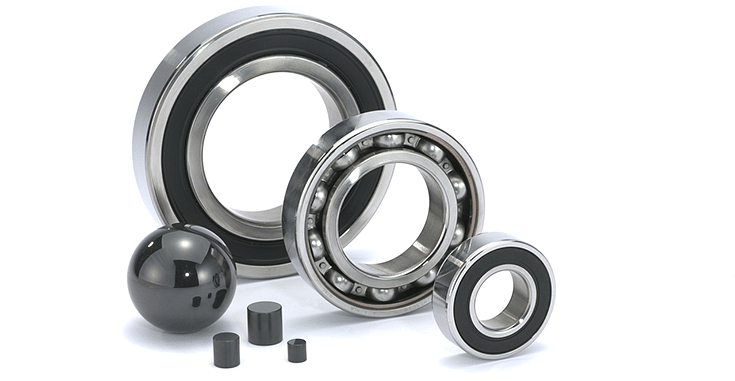

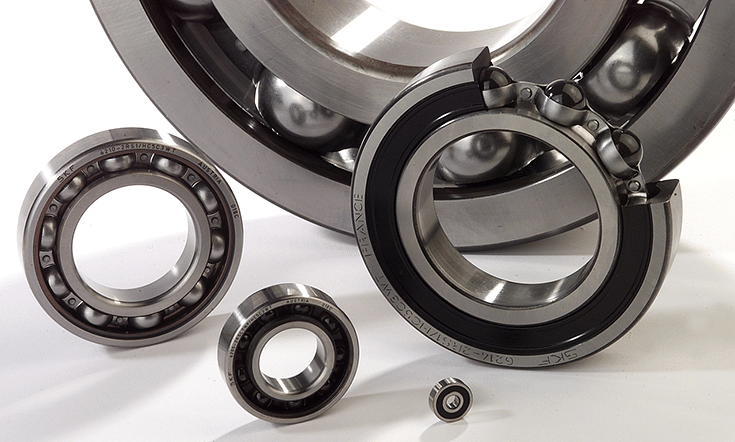

The company says that the global EV megatrend is pushing players like SKF to work more closely with its automotive customers to design systems which are focused on sustainability, and produce lesser carbon emissions. As a result, the company is witnessing strong offtake for hybrid bearings in markets like China and Europe, where EV penetration is already at a reasonable level compared to other emerging markets like India.

SKF's EV-focused hybrid bearings see a strong offtake in Europe and China where EV penetration is reasonably higher than emerging markets like India.

SKF's EV-focused hybrid bearings see a strong offtake in Europe and China where EV penetration is reasonably higher than emerging markets like India.

Designing India-specific solutions

“Since most of these electric vehicles for India are currently being designed, it will bring a very positive impact on our business by the end of this decade,” Annika Ölme, Global CTO and SVP, Technology Development, SKF Group, told Autocar Professional.

In terms of technology development, the SKF Group has deep collaborations among its global technology centres, and its team in India is focused on developing solutions, particularly for the India and South-East Asia markets. “India is a key part of our global engineering footprint, and is also a key pillar to support our regional markets – India – as well as South-East Asia, Australia, and New Zealand. We do product adaptations, as well as product engineering to suit customer and industry needs,” said Ölme.

The company says having local competency in proximity to its customers, enables SKF to work more closely with its clients, including the likes of Maruti Suzuki India, Tata Motors, Bajaj Auto, and Mahindra & Mahindra, among others, across the two- and three-wheeler, as well as passenger and commercial vehicle segments in the country.

“We see a higher growth potential in the India and South-East Asia market over other regions in the coming years, and therefore, it is a very important market for us. The GTCI is expanding for that reason, and we are increasing our collaboration globally. We see a huge strength in the development team that we have built in India over the last 20 years,” she added.

While the bearings major’s 300-member-strong engineering workforce in India across Bengaluru and Pune is driving projects for global markets, the company has also set up an innovation lab to keep up with the rapid pace of change in technology.

“There are players coming from different fields into automotive, and AI and digitisation are taking big strides, and emerging as the key pillars driving sustainability in the present day. Geopolitical factors are also influencing business, and that is why we are strengthening our regions to have a sustainable, full-value-chain business in India and South-East Asia. And therefore, we are doubling down upon on innovation, and taking new steps,” Ölme pointed out.

The GTCI is also working on the localisation of SKF’s products in India. In this regard, supplier discussions, new material innovation, as well as customer support are some of the key operations being undertaken at the GTCI, which is also developing products for the aftermarket.

“Given that the two- and three-wheeler markets are highly dominant in India, we also have Centres of Excellence for two- and three-wheelers at the GTCI. We see some unique competencies coming out from our the GTCI in these areas,” remarked Ölme.

SKF's hybrid bearings use a combination of traditional steel rings precision matched with silicon nitride (ceramic) balls that prevent current from passing through the bearing and prevent failure of mechanical parts of an EV.

SKF's hybrid bearings use a combination of traditional steel rings precision matched with silicon nitride (ceramic) balls that prevent current from passing through the bearing and prevent failure of mechanical parts of an EV.

Eyeing material innovation, driving sustainability

With sustainability being a key driver for the company, SKF is constantly undertaking material innovation, wherein green steel, and bio-based lubricants, are some of the prime examples of alternative materials being increasingly brought into applications in its products.

With its rich heritage in aerospace, SKF is also deploying its lightweighting learnings into the development of EVs that demand weight optimisation to extract the maximum battery range. “While there are some material technologies that help us lower weight, downsizing of the bearing hub itself is another way of achieving weight reduction in a system,” explained Ölme.

Sustainability-target-driven OEMs are also pushing SKF to switch to alternative materials such as green steel. “Today, automakers are ready to pay for greener materials; that was not the case five years ago. Therefore, it is a demand from our customers, and they are willing to pay more,” she said.

While SKF is collaborating with its steel suppliers to increasingly use scrap steel into its bearings, “Scrap steel can only cater to about 30 percent of the steel needs of the world, and therefore, we cannot fully rely on that. Therefore, there is a need for hydrogen-reduction-based green steel generation, which requires extensive investments,” Ölme pointed out.

To manage rising costs, especially with the use of alternative materials, the company is implementing several measures to drive cost reduction related to innovation. “We are looking at material innovation, heat treatments, as well as how to design for cost. There are a lot of things going on across different fronts,” said the SKG Group CTO.

While the company is switching to green steel in global markets, it is yet to do so in India but will follow in the OEMs’ footsteps. SKF is also realising a strong focus on industry-academia collaborations to drive innovation in material technologies. The company collaborates with the academia in markets like Europe, China, and the US, and wants to replicate the same in India.

SKF has five shared PHD programs with the Imperial College, London, wherein researchers are doing extensive work in the fields of tribology – the mechanism of lubrication around a bearing – and how that works on a nano level. “We are looking not only at long-term PHD work, but the industry trend now is for companies to work together with academia on a short-term basis, and bring the knowledge to the market quicker,” Ölme said.

Leveraging alternative manufacturing technologies

According to Ölme, additive manufacturing is another technology that promises to be a long-term solution to slash weight of components. “Additive manufacturing allows us to do lattice structures and use alternative materials. Of course, today the cost of additive manufacturing is a bit too high, but we have made 3D-printed bearings for racing,” she cited.

“We have used electron-beam powder-bed fusion technology and used bearing steel which is a coal-alloyed steel material with extremely high hardness. While the technology is there, it is the industrialisation, scalability, and the cost that needs to improve,” she said.

“If we look 10 years ahead, a redesigned bearing with lattice structures produced by additive manufacturing is going to be a big thing. While the scalability of additive manufacturing is already there in the areas of aerospace, and healthcare, the technology needs to mature further. It is going to be a very interesting technology in the future,” Ölme prophesized.

The company says the higher rotating speeds in EVs as well as the risk of passage of current through the mechanical system is emerging as a key factor driving the need for more reliability, insulation, as well as better lubrication in these products. “Therefore, the bearing, as a component, becomes even more critical. For us, the EV megatrend is playing an important role in driving innovation and technological advancement,” she signed off.

Clearly, the India market, which is witnessing a growing shift to electric mobility across vehicle segments, will continue to have a strong bearing on the SKF Group’s global growth plans.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

09 Feb 2024

09 Feb 2024

11493 Views

11493 Views

Autocar Professional Bureau

Autocar Professional Bureau