Continental begins production of tyre pressure monitoring system in India

Becomes first Tier 1 supplier to manufacture TPMS for cars in India; current production will cater to the local market and will expand to export markets over the next couple of years.

Technology company Continental has launched the production of its Tyre Pressure Monitoring System (TPMS) for passenger cars, at its Bangalore plant.

With the localisation of TPMS, Continental is enhancing its commitment to support local OEMs in India. In the next three years, Continental aims to rapidly scale up the TPMS production capacity. At present, the company is the first Tier 1 supplier to manufacture TPMS in India, providing safer, more sustainable, and inclusive mobility. The current production will cater to the local market and in the next two years the scope will be expanded to the export markets as well.

Ramnath Sivaraman, Head of Motion Technologies and Services, Continental Automotive India said, “At Continental, we are committed to India and its growing market needs. At present, safe mobility is a high-interest topic among consumers who are consistent in their expectations for the latest safety technologies in vehicles. The launch of TPMS will complement the overall vision for safe mobility in India. In addition, TPMS will also aid the cause of clean mobility by indicating the driver on maintaining optimal tyre pressure. We are in a good position to support local OEMs with respect to growing demands for advanced technologies at an affordable cost.”

Phanindra Karody, Head of Bangalore Plant, Continental Automotive India added, “Continental has a determined focus for localisation. The newly launched TPMS line features state-of-the-art smart manufacturing processes. This includes a fully automated assembly line with collaborative robots (Cobots) and a system that enables digital traceability. In our localisation efforts, we will continue to expand the production of the TPMS line based on market demand. In the next three years, we aim to rapidly scale up the production capacity and advance our export scope. Our smart manufacturing system at the plant will help us achieve our expansion goals in line with yearly targets.”

TPMS and its many benefits

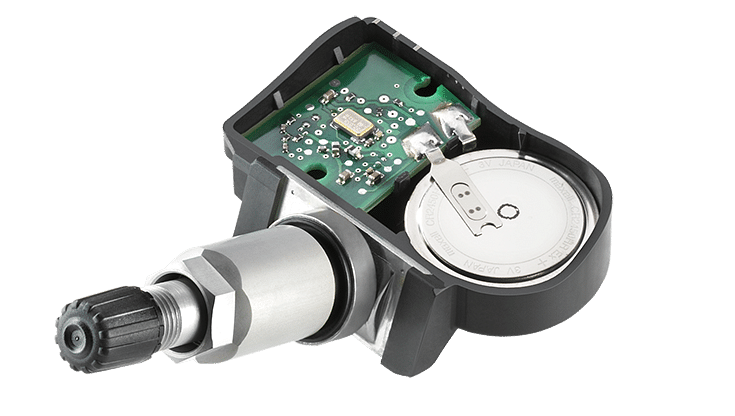

TPMS measures the pressure, temperature, and detects the motion of the tyre from the inside, and transmits the information through radio frequency and the vehicle communication network to a display in the instrument cluster. Providing accurate and timely information to the driver about the status of the tyres, for example, the tyre pressure and temperature for each wheel position. This information is crucial for the driver to maintain optimal air pressure to maintain vehicle safety and also efficiency.

Data, software, and AI are transforming the future of mobility. With vehicles entering the era of being software-driven, they become computers on wheels. To enhance TPMS usability and benefits for the end user, Continental, in its unique position, offers innovative add-on TPMS features, such as advanced 'problem tyre' localisation functions and ultraconvenient Smartphone Apps such as Filling Assistant and Tire Data.

With a reliable and absolute measured tyre pressure and temperature, TPMS offers cost savings due to optimised tyre usage due to driving at recommended tyre pressure for optimal rolling resistance, enhanced driving safety, reduced fuel consumption, less CO₂ emission, and an extended battery range for electric vehicles. Additionally, TPMS boasts of increased mobility safety by early leakage detection and it can be implemented as a stand-alone or integrated system solution. TPMS has a lifetime of up to 10 years, its operating temperature is -40 to 120deg C, and it weighs 37 g.

Industry 4.0 enables smart localisation

In its quest of establishing a sustainable manufacturing ecosystem, Continental has adopted digitisation and automation of various processes. The Bangalore plant is the largest electronics manufacturing plant of Continental in India and is symbolic of a smart factory.

Technologies such as Cobots, Augmented Reality, Artificial Intelligence for face recognition, automated replenishment systems, automated optical inspection, automated guided vehicles, and Big Data applications are implemented on the shop floor, help in operational efficiency, meeting quality standards, staying consistent in precision and maintain a high level of transparency. Smart manufacturing processes offer a strategic advantage in swift localisation and faster product-to-market solution.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

24 Apr 2023

24 Apr 2023

6056 Views

6056 Views