Yamaha to display latest factory automation tech at Hannover Messe 2019

The Yamaha booth will showcase demonstrations such as the ‘Linear Conveyor Module LCM 100’, a linear motor-based transport robot, and a SCARA robot which boasts high speed and high accuracy.

Yamaha Motor Co has announced today that it will exhibit a booth based on the theme of ‘Yamaha Robot Best Solution – Improved Production Line Performance’, at the Hannover Messe 2019, a B2B industrial technology trade show to be held in Hannover, Germany, from April 1 to April 5.

The Hannover Messe is the world's leading industrial trade fair, at which leading-edge industrial technology and products are gathered in one place. The 2018 event saw exhibits from approximately 6,500 companies attracting around 220,000 visitors.

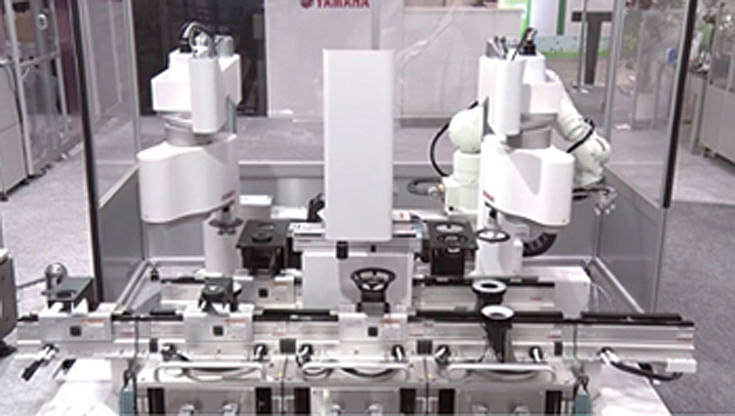

The Yamaha booth will showcase demonstrations such as the ‘Linear Conveyor Module LCM 100’, a linear motor-based transport robot, and a SCARA robot which boasts high speed and high accuracy. These exhibits work toward greater productivity and improved variability on production lines, providing best solutions for factory automation.

Linear Conveyor Module LCM100: The LCM 100 can transport workpieces at high speed and can be assembled directly on the slider, so that the transfer time is shortened considerably. In addition, with linear motor control, it is possible to change the stop position and process similar operations, bringing greater production line designs with higher levels of variability.

On-the-fly Function Demonstration (non-stop recognition camera): Robot Integrated Vision System iVY 2 and Multi-Axis Controller RCX 340 is a function that can shorten pick-and-place takt times with position correction after test piece handling. With the robot-integrated vision system iVY2, through the multi-axis controller RCX 340 capable of synchronous operation with multiple stand robots, recognition, correction and mounting can be performed without stopping robot operation, working to help improving throughput significantly.

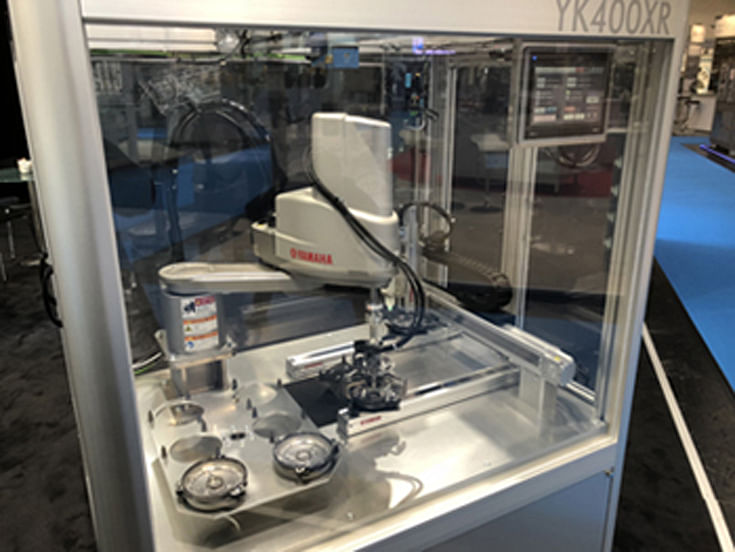

Auto parts sealing demonstration – SCARA robot YK 400 XR and Cartesian robots: With the SCARA robot ‘YK 400 XR’ boasting a standard cycle time of 0.45 seconds, the dual lane-assembled Cartesian robot greatly shortens the cycle time of the coating process. For test pieces on Cartesian robots with two lanes, one carries out coating, while the other replaces the test piece using a SCARA robot. As a result, the work ratio of the dispenser is improved which significantly increases productivity.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

04 Mar 2019

04 Mar 2019

8197 Views

8197 Views

Ajit Dalvi

Ajit Dalvi