Renault to use Continental’s innovative 48-volt hybrid drive

From end-2016, diesel variants of the Renault Scénic and Grand Scénic models will be equipped with Continental's 48-volt hybrid drive, which offers significant fuel consumption savings and reduced NoX emissions at moderate costs.

Global supplier Continental is helping electrify one diesel variant of both the new Renault Scénic and Grand Scénic models.

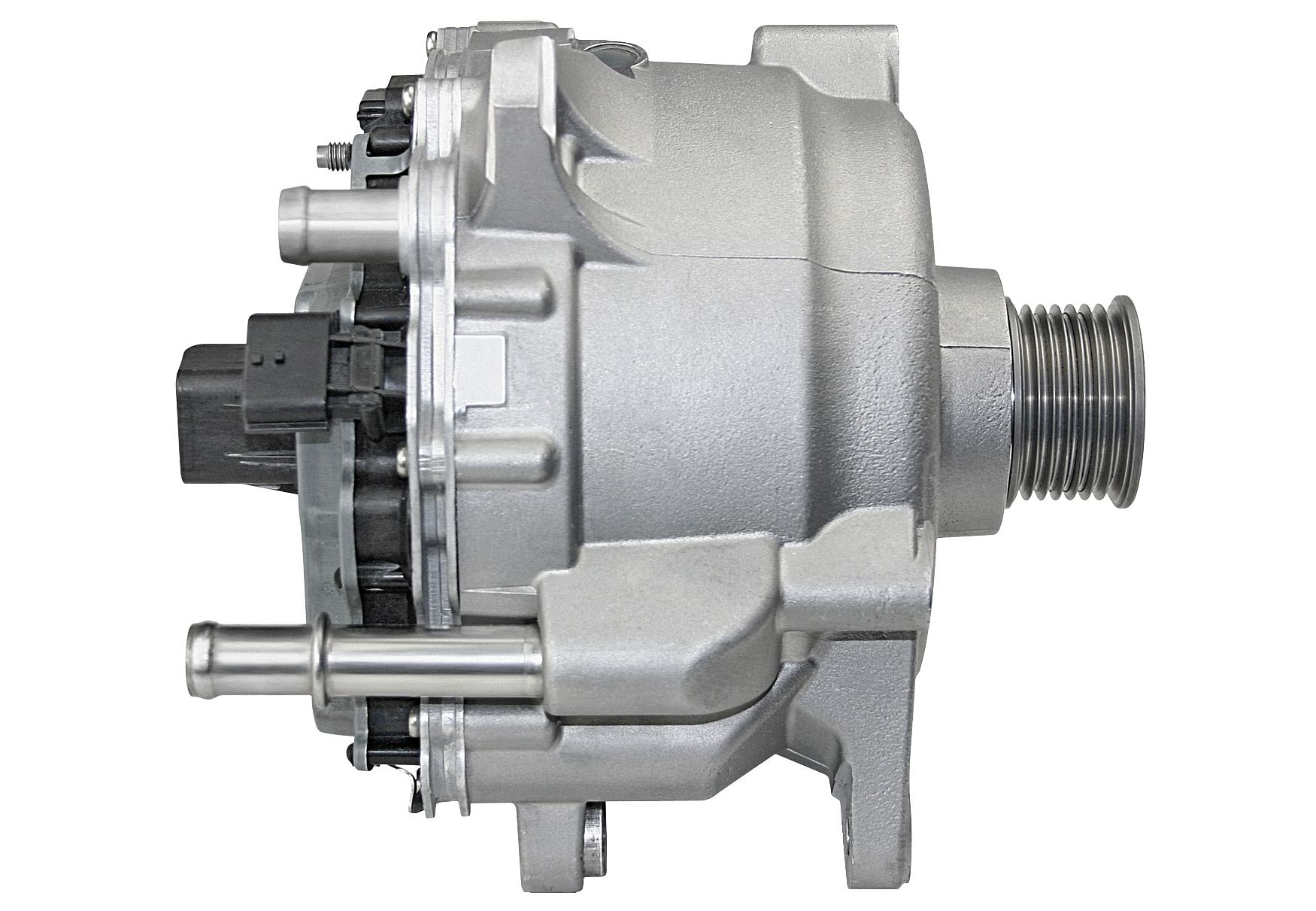

The system, offered as a ‘Hybrid Assist’ uses a 48-volt hybrid drive in production vehicles for the first time. The technology is a particularly cost-efficient solution to significantly reduce fuel consumption and exhaust emissions. Instead of the conventional starter generator, the system uses an electric motor with a continuous output of six kilowatts (10kW temporary), which drives the crankshaft of the engine via a belt. The electric motors with integrated inverter are supplied from the Continental plant in Nuremberg.

Since 2013, Continental engineers have been working together with Renault on a hybrid drive, which is so cost-efficient to produce that it becomes an appealing option for midsize vehicles. To achieve this, the development partners have used low-voltage hybrid technology, which operates at 48 volts. This is in contrast with the considerably more expensive high-voltage technology, which operates at between 300 and 400 volts and is usually used in hybrid vehicles. However, the 48-volt system facilitates significant savings.

Therefore, with the mild-hybrid system, Renault is aiming for combined fuel consumption of 3.5 litres of diesel per 100 kilometres. The French carmaker also aims to reduce the new Scénic´s CO2 emissions to 92 grams per kilometre, which is a new CO2 benchmark in this vehicle class. This is possible because the electric motor, operated as a generator, also converts a large proportion of the braking energy into electricity, which is temporarily stored in a small battery. This electricity can then be specifically used to relieve the internal combustion engine. This is also the reason why nitrogen oxide emissions and exhaust particles, especially in urban traffic, are reduced when a 48-volt drive is combined with a diesel engine.

The belt-driven starter generator (48-volt electric drive).

"We are proud that we were able to secure Renault as the first customer for our innovative 48-volt drive," said José Avila, Continental Executive Board Member responsible for the Powertrain Division. "Other production launches for both diesel and petrol vehicles are in the pipeline for Europe and other markets including China and North America." According to Continental, the market for 48-volt drives will experience significant growth in the coming years. As Rudolf Stark, Head of the Hybrid Electric Vehicle Business Unit, assumed, "in 2025, approximately one in five new vehicles across the world will be equipped with a 48-volt drive."

Continental says the 48-volt solution is relatively easy to combine with pre-existing internal combustion engines, as it does not require any more room than a conventional starter generator. This is due to the high power-to-size ratio of the electric motor, which does not contain rare earth materials. This is achieved by water cooling of the stator and the high efficiency of the induction motor.

To save space, the inverter, which is needed to convert direct current stored in the battery into alternating current required for operation, is integrated in the housing lid of the motor. The ready-to-install 48-volt drive is manufactured at the Continental plant in Nuremberg, which already specialises in complex electronic modules, such as those used for automatic transmissions.

In addition to designing the 48-volt drive for the crankshaft of the internal combustion engine in Renault vehicles, Continental is also working on other solutions. The electric motor can also be placed between the engine and transmission – allowing, for example, purely electric driving in inner city areas.

You may like: Nissan reveals new electric motor drivetrain, e-Power

RELATED ARTICLES

Volvo Cars signs recycled steel supply pact with SSAB

The recycled steel will be used in selected components of the forthcoming, fully electric EX60 SUV, as well as other car...

Schaeffler and NVIDIA ink technology collaboration to advance digital manufacturing

Using NVIDIA Omniverse, Schaeffler is expanding its production elements, which will be integrated and simulated as digit...

BMW Group to industrialise Virtual Factory, slash production planning costs

What once required several weeks of real-world modifications and testing can now be precisely simulated in the BMW Group...

By Autocar Professional Bureau

By Autocar Professional Bureau

03 Nov 2016

03 Nov 2016

10211 Views

10211 Views