Nissan tests cool paint technology that can beat the heat

Embedded metamaterial can lower cabin temperatures and reduce energy usage, taking the heat out of summer; trials confirm up to 12-deg Celsius reduction in exterior temperatures and up to a 5-degree Celsius cooler interior.

Nissan has been trialling an innovative automotive paint aimed at helping lower a vehicle’s ambient cabin temperature in summer and reduce the energy usage of the air-conditioning system.

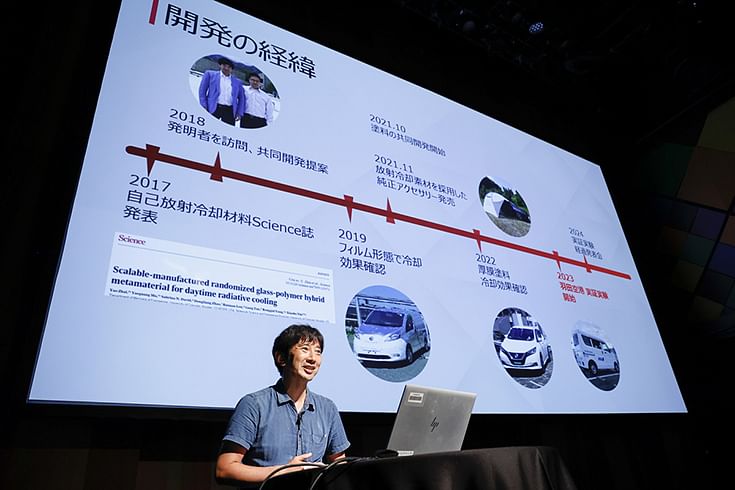

Developed in partnership with Radi-Cool, a specialist in radiative cooling products, the paint incorporates metamaterial, synthetic composite materials with structures that exhibit properties not usually found in nature.

In November 2023, Nissan commenced a 12-month feasibility trial at Tokyo International Air Terminal at Haneda. In collaboration with Japan Airport Terminal Co., Ltd., Radi-Cool Japan, and All Nippon Airways (ANA) airport service, Nissan’s cool paint has been applied to a Nissan NV100 service vehicle operated by All Nippon Airways (ANA) airport services.

A vehicle treated in Nissan’s cool paint has shown yields of up to a 12-deg C reduction in exterior surface temperatures and up to 5-deg C cooler interior, compared to a vehicle featuring traditional automotive paint.

A vehicle treated in Nissan’s cool paint has shown yields of up to a 12-deg C reduction in exterior surface temperatures and up to 5-deg C cooler interior, compared to a vehicle featuring traditional automotive paint.

Impressive initial results

With its large, open tarmac, Haneda airport provided the perfect environment to conduct real-world evaluation of the paint’s performance under an exposed high-temperature environment.

Although still in testing phase, the results to date have been impressive. Parked side-by-side under the sun, a vehicle treated in Nissan’s cool paint has shown yields of up to a 12-degree Celsius reduction in exterior surface temperatures and up to 5-degree Celsius cooler interior, compared to a vehicle featuring traditional automotive paint.

The paint’s cooling performance is particularly noticeable when a vehicle is parked in the sun for an extended period. A cooler cabin is not only more pleasant to enter, but also requires less air-conditioning run-time to cool the cabin to a comfortable temperature. This helps reduce load to the engine, or in the case of an electric vehicle, draw on the battery. In both powertrains, an improvement in efficiency is expected, as well as occupant comfort.

The metamaterial embedded within Nissan’s cool paint features two microstructure particles that react to light. One particle reflects near-infrared rays in the sunlight that would typically cause molecular level vibrations within the resin of traditional paint to produce heat.

The second particle enables the real breakthrough. It creates electromagnetic waves, that counteract the sun's rays, redirecting the energy away from the vehicle into the atmosphere. Combined, the particles in Nissan’s cool paint reduce the transfer of heat into surfaces such as the roof, hood, doors and panels.

Dr. Susumu Miura: “My dream is to create cooler cars without consuming energy. This is especially important in the EV era, where the load from running air-conditioning in summer can have a sizeable impact on the state of charge."

Dr. Susumu Miura: “My dream is to create cooler cars without consuming energy. This is especially important in the EV era, where the load from running air-conditioning in summer can have a sizeable impact on the state of charge."

Nissan expert heading the project

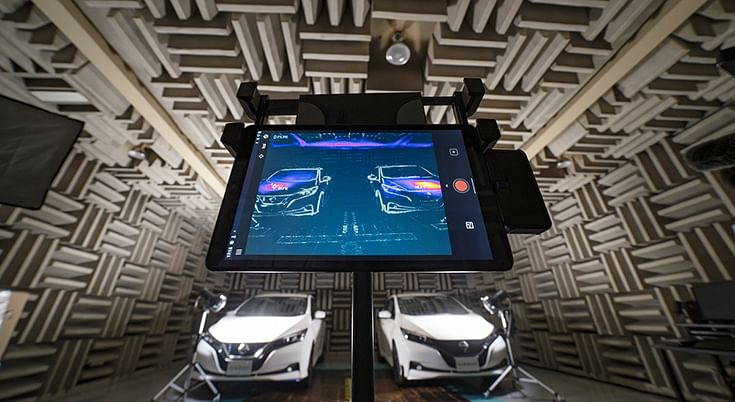

Leading the development is Dr. Susumu Miura, senior manager and expert at the Advanced Materials and Processing Laboratory, Nissan Research Center. He played a leading role in Nissan’s award-winning noise-reducing acoustic material, and has dedicated much of his career at Nissan to exploring ways to make cars quieter, cooler and more efficient.

“My dream is to create cooler cars without consuming energy,” explained Miura. “This is especially important in the EV era, where the load from running air-conditioning in summer can have a sizable impact on the state of charge,” he said.

While radiant cooling paint isn’t new, it is typically used for buildings and structures. It’s often very thick, requiring application by a paint roller. Devoid of any clear topcoat, it can leave a chalky residue when touched.

Key challenges Miura had to consider when developing an automotive version, was to ensure it could incorporate a clear topcoat, be applied via a spray gun (not a roller), and meet Nissan’s rigorous internal standards for paint quality.

Since commencing the development in 2021, Miura and his team have tested over 100 samples, and are currently evaluating a thickness of 120 microns, approximately six times thicker than typical automotive paint. They have confirmed resistance to salt and chipping, peeling, scratches, chemical reactions, along with colour consistency and repairability. As development progresses, Miura and his team continue to explore thinner options that deliver the same level of cooling performance.

While the testing and development is ongoing, for Miura and his team, the hope is that it can one day be offered for special orders and in a variety of colours.

Miura foresees strong potential, particularly for light commercial vehicle applications such as vans, trucks and ambulances that spend most of the day out driving.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

07 Aug 2024

07 Aug 2024

2447 Views

2447 Views

Ajit Dalvi

Ajit Dalvi