Mercedes-Benz's upcoming pilot battery recycling plant to have over 96% recovery rate

Innovative mechanical-hydrometallurgical process enables recycling rate to more than 96%; mechanical dismantling of batteries to begin this year

Mercedes-Benz held a ground-breaking ceremony for a new battery recycling factory in Kuppenheim, Germany, yesterday. The facility is aimed at cutting resource consumption and establishing closed-loop recycling of battery raw materials.

The first stage of the plant – mechanical dismantling of electric vehicle batteries – is scheduled to start ramping up at the end of this year. Subject to the outcome of promising discussions with the public sector, a hydrometallurgy pilot plant will be established only a few months later.

This innovative approach for an integrated recycling concept within a single factory is currently unique in Europe. Mercedes-Benz is investing a double-digit million euros amount in the construction of the balance sheet CO2-neutral plant, which is funded by the German Federal Ministry of Economics and Climate Protection as part of a scientific research project.

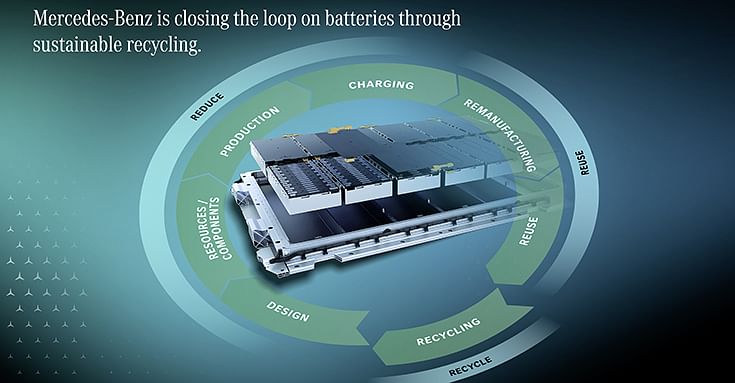

Circular economy of battery materials

In future, the Mercedes-Benz battery recycling factory in Kuppenheim will cover every step -- from dismantling at the module level, to shredding and drying and processing of battery-grade materials. The hydrometallurgy process with a recovery rate of more than 96% enables a true circular economy of battery materials.

Mercedes-Benz is partnering technology partner Primobius for the project. As part of the overarching scientific research project, the entire process of battery recycling is also taken into account: From the development of logistics concepts, through the sustainable recycling of valuable raw materials, to the reintegration of recyclates into the production of new batteries.

The pilot plant is expected to have an annual capacity of 2,500 tonnes. The recovered materials will be fed back into the recycling loop to produce more than 50,000 battery modules for new Mercedes-Benz models. Based on the findings of the pilot factory, production volumes could be scaled up in the medium to long term.

"This foundation symbolises the decisive step towards closing the material cycle for batteries from Mercedes-Benz. With a recycling rate of more than 96 percent, a 'mine of tomorrow' is being created here in Kuppenheim. The innovative technology approach enables us to incorporate the valuable raw materials into new Mercedes-EQ vehicles. We are consistently expanding our expertise of the battery value chain and are taking an important step in our strategy towards 'Electric Only',”said Jorg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production and Supply Chain Management

"I am delighted that Mercedes-Benz is taking on a pioneering role with the pilot factory for battery recycling here in Kuppenheim. This is of particular importance in view of the limited availability of important and highly sought-after raw materials such as lithium, cobalt or nickel. Increased recycling can help to reduce this dependence on critical raw materials and thus strengthen the resilience of the economy,” said Thekla Walker MdL, Minister for the Environment, Climate Protection and the Energy Sector Baden-Wurttemberg.

In addition to CO₂-neutral production and the switch to an all-electric vehicle portfolio, a closed loop of recyclable materials is also crucial to reducing resource consumption.

In addition to CO₂-neutral production and the switch to an all-electric vehicle portfolio, a closed loop of recyclable materials is also crucial to reducing resource consumption.

Holistic approach to battery value creation

Mercedes-Benz is taking a holistic approach to the circular economy of battery systems, looking at three core issues: Circular design, value retention and closing the loop.

During the development of a vehicle, the company creates a concept for each vehicle model in which all components and materials are analysed for their suitability in the context of a circular economy. Material recycling of the raw materials used, such as lithium, nickel, cobalt, is an integral part of this approach, and also begins with the design of the components. This approach covers the entire supply chain from mining to recycling.

A high level of attention is also paid to the observance of human rights in the working conditions of employees. Mercedes-Benz offers reconditioned batteries as replacement parts for all EVs, in order to comply with the idea of a closed economic loop and to conserve resources. In addition, the carmaker has established a successful business model with stationary large-scale energy storages through its subsidiary Mercedes-Benz Energy. Batteries that can no longer be used in vehicles can continue to be used in a second-life storage system.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

04 Mar 2023

04 Mar 2023

5787 Views

5787 Views

Ajit Dalvi

Ajit Dalvi