Six Japanese companies join forces to expand use of recycled materials in new vehicles

Denso, Toray Industries, Nomura Research Institute, Honda Motor, Matec Inc and Rever Corporation have set up the BlueRebirth Council, which aims to build a manufacturing and recycling integrated value chain to realize Car-to-Car recycling, starting with automated precision dismantling, which efficiently disassembles end-of-life vehicles for material recovery and recycling.

Denso Corporation, Toray Industries, Nomura Research Institute, Honda Motor Co, Matec Inc, and Rever Corporation have set up the BlueRebirth Council. Initiated by these six companies, the Council aims to build a manufacturing and recycling integrated value chain to realize Car-to-Car recycling, starting with automated precision dismantling, which efficiently disassembles end-of-life vehicles (ELVs) for material recovery and recycling.

In recent years, the automotive industry has sought to transition to a circular economy to help realize a sustainable society, taking on the significant challenge of reducing natural resource consumption by greatly expanding the use of recycled materials. However, the mainstream global method remains shredding ELVs followed by material sorting, which makes it extremely difficult to secure high purity recycled materials.

Furthermore, collaboration between manufacturing and recycling industries has not been sufficient, and as a result, initiatives to use recycled materials as automotive components — which require both high quality standards and adequate supply volumes for mass production — have not progressed sufficiently. In addition, the automotive recycling industry faces challenges in promoting automation and digitalization and in addressing worker shortages by improving workplace environments.

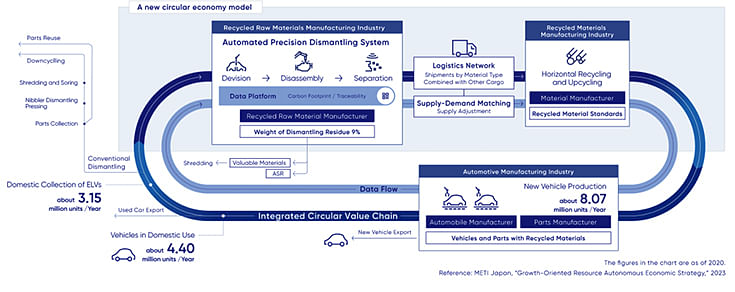

The BlueRebirth Council aims to address these challenges and, looking ahead to 2035, evolve the automotive recycling industry into a “recycled materials manufacturing industry” that plays a key role as part of a new resource-circulating value chain within the automotive industry. Through these efforts, the companies behind the Council are committed to realizing a true Car-to-Car recycling system.

The BlueRebirth Council aims to build a manufacturing and recycling integrated value chain to realize Car-to-Car recycling, starting with automated precision dismantling, which efficiently disassembles ELVs for material recovery and recycling.

The BlueRebirth Council aims to build a manufacturing and recycling integrated value chain to realize Car-to-Car recycling, starting with automated precision dismantling, which efficiently disassembles ELVs for material recovery and recycling.

As specific initiatives, the Council will engage in discussions and research, as well as advance technology development and demonstration projects together with participating companies, research institutions, and other stakeholders, starting with the automated precision dismantling of ELVs to build a manufacturing and recycling integrated value chain. In addition, we will make recommendations to relevant companies and organizations.

Automated precision dismantling is an advanced intelligent system that utilizes AI and sensor technologies to enable robots to operate along the optimal path even for deformed parts. This not only ensures the quality and volume of recycled materials that were difficult to achieve with conventional methods, but also contributes to fundamentally solving worker shortages.

Furthermore, by recording information such as material provenance and environmental impact on a digital platform and sharing it across the manufacturing and recycling value chain, the six companies can ensure a reliable and stable supply of recycled materials.

The Council states that it “is committed to expanding the use of recycled materials in automotive recycling and building a manufacturing and recycling Integrated value chain toward a Car-to-Car model.” Through these efforts, the companies aim to contribute to the realization of a circular economy in the automotive industry.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

30 Jun 2025

30 Jun 2025

4609 Views

4609 Views

Ajit Dalvi

Ajit Dalvi