Hyundai develops world first active shift control tech for hybrids

Active Shift Control transmission technology improves gear-shift efficiency for hybrid vehicles and is now set for mass production; reduces gearshift times by 30%, adds to driving fun, and improves fuel economy.

Hyundai Motor Group has developed the world’s first Active Shift Control (ASC) transmission technology. The innovation optimises transmission efficiency by monitoring gearshifts 500 times per second, precisely adjusting the transmission rotation speed to for faster shift times.

The new technology will premiere in the upcoming Hyundai Sonata Hybrid and eventually benefit other upcoming Hyundai and Kia hybrids.

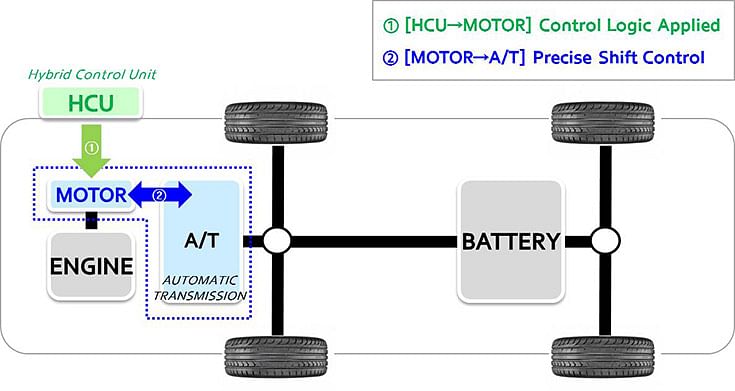

ASC applies new control logic software to the Hybrid Control Unit (HCU), which then controls the electric motor to align the rotational speeds of the engine and transmission to reduce gear shift time by 30 percent. The technology also delivers smoother gear changes despite quicker shift times.

“The development of world’s first ASC technology is a remarkable innovation which incorporates precise motor control to automatic transmission,” said KyoungJoon Chang, Vice President and Head of Powertrain Control System Group of Hyundai Motor Group, “It will not only save fuel but also provide a more fun driving experience for our customers.”

Reducing gear shift time by 30 percent

Conventional hybrid vehicles do not have torque converters in order to further improve fuel economy as torque converters lose energy during the process of transmission. Although fuel efficient, such a system also requires longer shift times to ensure smoother gear changes.

ASC technology allows the hybrid’s electric motor to also take control of gear shifts by applying new software logic to the Hybrid Control Unit (HCU) to mitigate issues with slower shift time. The HCU monitors the rotational speed of transmission with a sensor installed inside the electric motor at 500 times per second to quickly synchronise the rotational speed with that of engine.

With the synchronisation, shift time is reduced by 30 percent from 500ms to 350ms. This not only improves hybrid vehicle’s acceleration performance and fuel economy, but also durability of the transmission by minimising friction during gearshift.

Also read: Hyundai Motor India sales down 7.3 percent in June to 42,007 units

Hyundai Motor and Kia Motors invest 80m Euro in Rimac, will establish technology partnership too

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

19 Jul 2019

19 Jul 2019

9578 Views

9578 Views

Ajit Dalvi

Ajit Dalvi