Hyundai and Kia develop shape memory alloy integrated snow chain technology

Shape memory alloy located inside a wheel and tyre deploys easily to act as a snow chain at the touch of a button; patent-pending tech designed for repeated use, taking advantage of the shape memory alloy’s ability to return to its original shape.

Hyundai Motor Company and Kia Corporation today unveiled a new snow chain-integrated tyre technology to make it easier to stay safe in winter driving conditions.

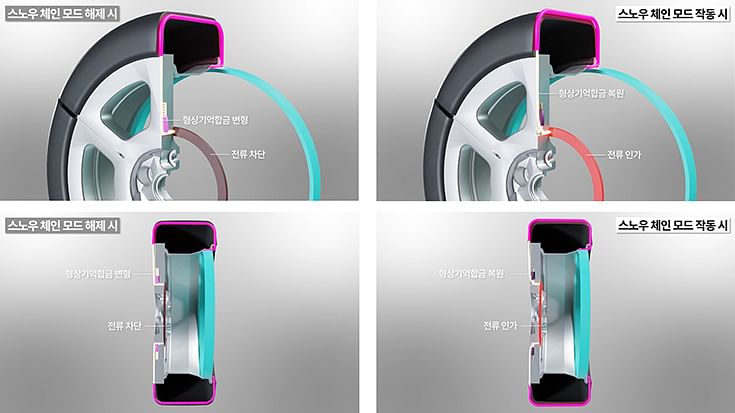

Snow chain-integrated tyre technology uses shape memory alloy modules that are located inside the wheel and tyre. These modules protrude to act as a ‘snow chain’ when an electrical signal is received.

Unlike traditional snow chains that are complicated to install and remove, this technology will automatically deploy shape memory alloy snow chains at the push of a button, helping to improve safety in snowy conditions.

“This innovation, which will hopefully be introduced on Hyundai and Kia vehicles someday, reflects our commitment to turning advanced technologies into real-world solutions that benefit customers,” said Joon Mo Park, Head of Advanced Chassis Development Team. “We will continue to develop technologies that enhance safety and convenience of our vehicles and bring value to our customers.”

The snow chain-integrated tyre technology consists of a wheel and tire assembly that feature radial grooves at regular intervals, like a pizza, with modules made of shape memory alloy inserted into these channels.

This technology takes advantage of the shape memory alloy’s ability to return to its original shape when an electric current is applied. During normal driving, the shape memory alloy located inside the wheel is compressed into the shape of the letter ‘L’ and does not contact the road surface. When the driver activates the function, an electric current is applied, causing the shape memory alloy to revert to its original profile; the material forms a ‘J’ shape, pushing the module out of the tire to make contact with the surface, improving grip, stability and safety on snowy roads.

If the surface of the tyre is worn down to the height of the module in normal driving mode due to severe tire wear, drivers can easily recognize this degradation so as not miss the tyre replacement cycle.

The technology is patent-pending in both South Korea and the U.S. Hyundai Motor and Kia plan to consider mass production of the tires after further technological development, durability and performance tests and regulation reviews.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

11 Dec 2023

11 Dec 2023

6631 Views

6631 Views

Ajit Dalvi

Ajit Dalvi