Covestro reveals innovation-laden EV concept at K2016 plastics expo

The EV concept car incorporates current trends in exterior design and its stand-out features include transparent polycarbonate wraparound glazing, seamless design of the front end, and an entirely new lighting solution.

Nearly 50 years after Covestro, then operating under its former name Bayer, introduced the first car with a plastic body at the plastics trade show – the K 67 – the materials manufacturers has taken the covers off an all-new concept for designing electric vehicles.

The global platform for the reveal is K 2016, the world’s leading plastics trade fair which opens today in Düsseldorf, where Covestro AG is showcasing its innovative and sustainable material solutions (Stand A75, Hall 6). “We provide answers to some of the biggest challenges facing our world, and develop solutions that benefit both society and the environment,” said CEO Patrick Thomas at the kickoff of K 2016 yesterday.

“We have, for instance, discovered a way to turn the greenhouse gas carbon dioxide into valuable plastic products. This had not been possible until now because the CO2 molecule is very slow to react. We pushed existing boundaries, however, to develop a special catalyst that is key to the synthesis,” the Covestro CEO added.

The first mattresses and upholstered furniture made with the CO2-based foam, which find application in automotive interiors, are scheduled to be launched on the market before the end of year.

Visionary concept car

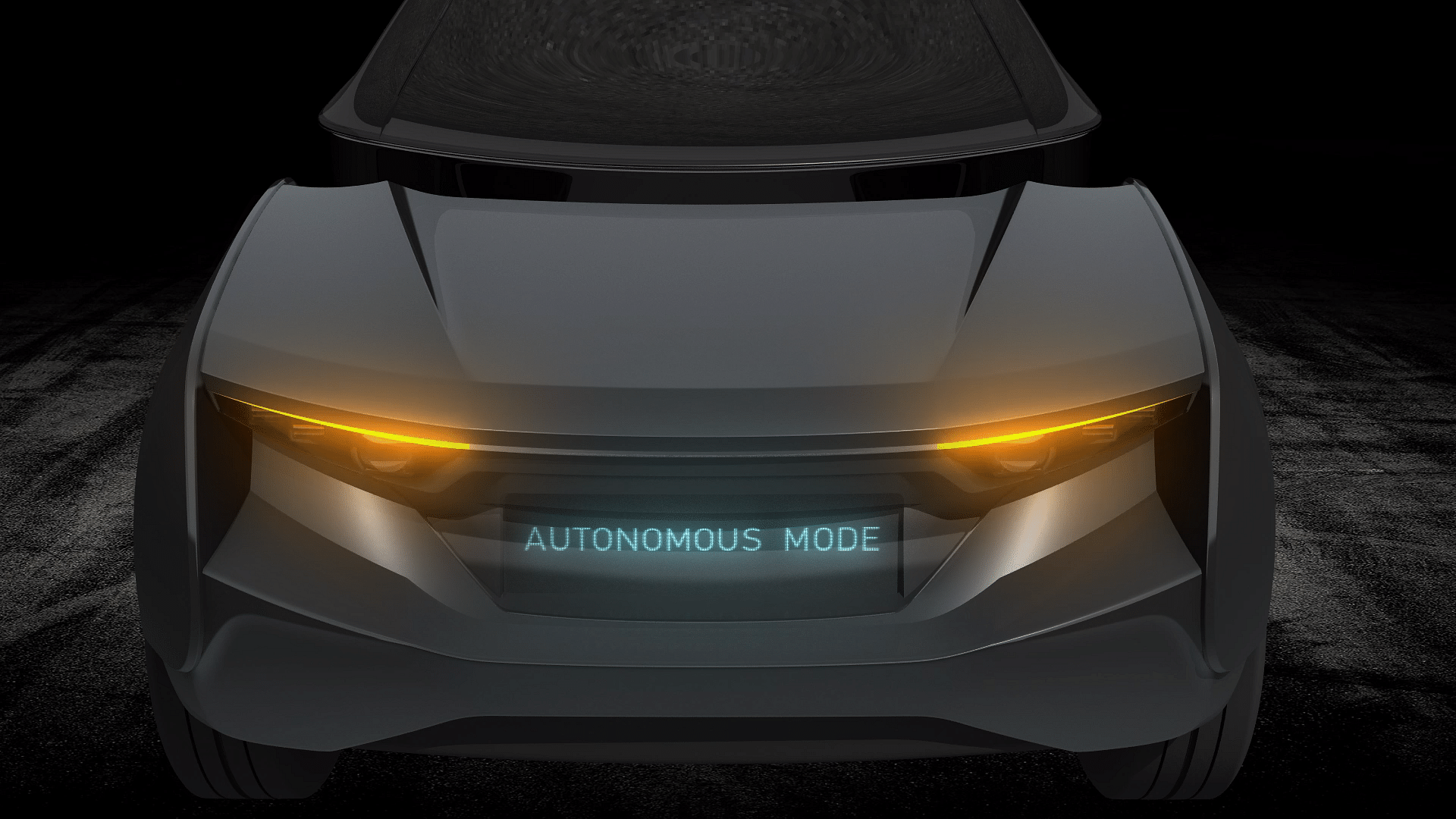

The highlight of Covestro’s display at K Trade Fair this year is the entirely new concept for designing EVs. The visionary concept is in the form of a contemporary electric car incorporating current trends in exterior design, including a polycarbonate wrap-around glazing and an entirely new lighting concept. developed in conjunction with lighting solutions specialist Hella.

The concept, developed in close collaboration with design students and partners in the auto industry, is based on pioneering plastics technologies. It incorporates current trends in exterior design, including a seamless front end, innovative holographic lighting, polycarbonate wrap-around glazing and the use of sustainable coating and adhesive systems.

“Our concept helps to expand electromobility, which is destined to make a major contribution to climate protection,” said project manager Jochen Hardt. “These developments are pushing boundaries, offering new solutions for attractively designing comfortable, functional and energy-efficient cars. They are our way of helping customers raise the bar on styling, functional integration, profitability and sustainability.”

Together with Hella, Covestro has developed an innovative solution based on holographic films, with which various light functions can be integrated into the body parts.

Redefining automotive lighting

Together with Covestro, lighting and electronics specialist Hella has developed a new design for vehicle signal lighting using holographic technology.

The two companies have been developing innovative designs for the front and rear lighting of electric cars in collaboration since 2015. The result is holographic lighting with 3D effects, as well as a seamless and aerodynamic design revealed on the show car at the K Trade Fair.

The rear of the vehicle is comprised of a lamp with three parts, each equipped with holographic technology. With this, the two companies are presenting a world premiere. Designers at Hella developed the holograms before Covestro then incorporated these into a transparent holographic film, which retains the design and is laminated onto a 3mm glass plate. For series applications in the future, plastic will be used instead of glass.

"Holographic films are perfectly suited for integrating different lighting functions into the body in a space-saving and unobtrusive way. The installation depth can be reduced and automotive manufacturers have the possibility to install more compact lamps," explains Dr. Michael Kleinkes, Head of Development Lighting Technology at Hella.

The holographic film is illuminated from behind using LED light sources and reflectors. This results in a 3D effect, as if the elements are floating freely in space. In both of the outer elements of the rear lamp, a hologram was inserted with numerous illuminating areas (‘flakes’). Integrated into the tailgate is the middle lamp, on which the Hella and Covestro company logos appear to be floating.

The design of the stop lamp that stands out at the rear of the vehicle. Instead of a separate centre high-mounted stop lamp, Hella has created a joint signature for the stop lamp and centre high-mounted stop lamp. "As the statutory regulations have been fulfilled, it would be possible to implement this approach in series applications immediately," says Dr. Michael Kleinkes.

The tail-light is also visually combined with the direction indicator. For this, a diffuser film with diffractive optics developed by Covestro is used. This forms and distributes light beams with minimal loss of light, thus ensuring uniform light distribution. The LEDs located behind this in the two outer parts are designed two-colored so that both the direction indicator and the tail light functions can be generated. The functions are also animated, meaning that the effect of a sequential turn signal can be realized, for example.

Hella and Covestro have not only redesigned the rear of the vehicle, but also the front. The companies have created a seamless, uniform surface. The signal functions have been realised with a three-part EdgeLight light guide. This spans the entire front of the vehicle as a continuous lighting strip. The two outer parts of the light guide create the direction indicator lights as well as daytime running lights, which can be dimmed to position lighting. The middle light guide is responsible for the continuous daytime running light and position light signature. These functions can also be animated. The area in front of the vehicle is illuminated using four so-called ComLED modules. The two main lighting functions of low beam and high beam lighting are executed by the matrix HD84 module developed by Hella.

LED displays are integrated in both the front and rear of the vehicle in order to enable additional animations, such as the welcome light function. In the future, this could not only be possible when stationary but also during driving, in combination with other light functions, for example. When braking, for example, it would be possible to illuminate not only the stop lamp, but also show the additional indicator ‘STOP’.

Another trend is seamless, homogeneous surfaces, which are about more than just aesthetics: The less drag a vehicle creates, the less energy it consumes or, in the case of electric cars, the greater their range. To help reduce drag, Covestro equipped its concept car with additional components to improve aerodynamics.

All-around visibility

Wraparound glazing made of transparent polycarbonate provides for better all-around visibility. Wraparound glazing rewards passengers with a panorama view, and enhances pedestrian safety because it almost entirely eliminates blind spots.

Covestro says the wraparound glazing made of transparent polycarbonate provides for better all-around visibility. Wraparound glazing offers passengers a panorama view, and enhances pedestrian safety because it almost entirely eliminates blind spots.

New developments in raw materials for coatings and adhesives are another part of the design concept. The coating hardener is made with biomass: 70 percent of its carbon content is of plant origin. Coatings formulated with this raw material achieve the same high-level properties as conventional coatings, even surpassing them in some cases. On top of that, they contribute to climate protection.

Another hardener enables plastic automotive add-on parts to be coated at low temperatures. In the medium term, this technology will offer the opportunity of coating plastic, composite and metal parts together for the first time. For more sophisticated demands, Covestro also has developed raw materials for transparent adhesives.

Material meets design

Covestro worked closely with various partners on its new automotive concept. For instance, the company invited students from the distinguished Umeå Institute of Design in Sweden and the Northern Works design agency in Finland, to Leverkusen. The purpose of the project was to shift existing boundaries between aesthetics and materials and to develop new ideas for design and functionality that fulfill the dreams of future drivers. The focus was on material solutions based on polycarbonate.

Read more: Covestro develops cost-efficient production tech for lightweight vehicle interior parts

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

19 Oct 2016

19 Oct 2016

14485 Views

14485 Views

Ajit Dalvi

Ajit Dalvi