Continental celebrates 120th anniversary of first tyre with tread pattern

World’s first tyre with a tread pattern featured simple hand-carved structure of circumferential grooves. Today, 120 years later, digital design and virtual testing are applied in pattern development.

With the development of the world’s first car tyre with a tread pattern and its market launch 120 years ago, Continental achieved a milestone in the history of mobility. At the time, personal mobility was still in its infancy. However, as the number of vehicles, their weight and the power of the engines increased, the demands placed on handling characteristics and safety steadily grew. Continental responded by introducing the first tyre ever having a tread pattern, significantly improving traction and shortening braking distances on wet and dirty roads.

Continental’s tyre developers have been perfecting this principle for over a century, leading to numerous other innovations in tyre design: from the first longitudinal to the V-shaped directional tread patterns of today and the most advanced AI-supported design developments of the future. As a result, the safety, efficiency and comfort of vehicles have been steadily improved. Tire lines from Continental such as the PremiumContact, EcoContact and WinterContact as well as the high-performance SportContact 7 model are just a few examples of this.

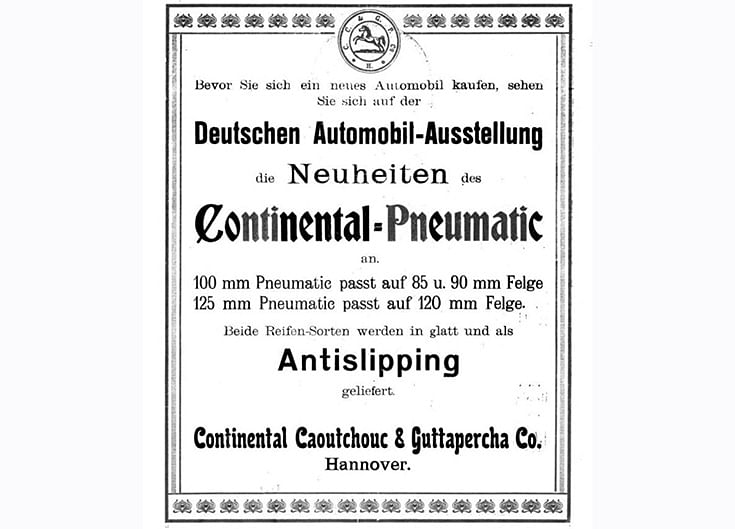

The revolutionary development of the first tyre with a tread was announced by Continental back in 1903 at the German Automobile Exhibition in Frankfurt.

The revolutionary development of the first tyre with a tread was announced by Continental back in 1903 at the German Automobile Exhibition in Frankfurt.

“The tread pattern of a tyre is not only an important distinguishing feature, but also has a major influence on the overall vehicle performance. With the first hand-carved tyres having a tread pattern 120 years ago, Continental revolutionized mobility worldwide. Since tyres were no longer smooth and unstructured in their contact area to the road, they were able to offer significantly more traction, grip and driving safety on wet, dirty and snow-covered surfaces. This is due to their sophisticated block, groove and sipe pattern structure,” explains Felix Hübner, Head of the department Pattern, Contour & Industrial Design at Continental Tires. “Today, new designs are digitally created, virtually tested and refined in further development. This allows us to continually improve the safety and efficiency of our tyres day by day, building on a success story that has lasted for more than a century.”

Today, the developers at Continental design tyre treads digitally and specifically for given requirements.

Today, the developers at Continental design tyre treads digitally and specifically for given requirements.

Tread pattern determines the safety of a tyre

Being the interface between the vehicle and the road, the tread pattern of a tyre is crucial for driving safety. The contact area of a car tyre is around the size of a postcard and transfers all the forces that occur when braking, accelerating and steering. On wet or snow-covered roads, the tread pattern absorbs water, slush or snow and effectively channels it away, improving the contact between the rubber and the road and preventing aquaplaning. Traction, noise, brake performance, wear behaviour and tyre abrasion also depend crucially on the tread design.

Today, tread patterns are developed specifically for different segments and applications. Examples include racing tyres and ultra-high-performance tyres for high speeds on public roads. There are also summer, all-season, winter, Nordic/ice and off-road tyres. Winter tyres, for example, with their many blocks, numerous sipes and grooves, are significantly more structured than summer tires, allowing them to better grip snowy surfaces and displace water and slush from the road surface.

Tread patterns suitable for specific applications

Tread patterns suitable for specific applications

Developers distinguish between three basic types of tread patterns:

The symmetrical tread pattern is universal and can be used in any direction, allowing the tyres to be fitted in any position. This is particularly advantageous for heavily used vans, especially in urban traffic with changing road conditions and frequent stops.

A directional tread pattern has a specific direction of rotation, offering a high degree of protection against aquaplaning and excellent handling on snow and slush. In addition, it provides very good directional stability at high speeds, making it a safe choice for winter road surfaces.

An asymmetrical tread pattern is characterized by excellent handling, high cornering stability and good grip on wet roads. It therefore offers the ideal combination of properties for wide, sporty summer tires.

Each tread pattern comprises four components:

Blocks are the protruding rubber parts of the tread pattern and are in direct contact with the road surface. They provide traction and grip, which are crucial for acceleration, braking and cornering.

Grooves are the spaces between the tread blocks. They serve to channel water away and reduce the risk of aquaplaning.

Ribs refer to the tread blocks arranged next to each other in a row. They ensure stability and improve the vehicle’s steering precision.

Sipes are the fine incisions in the tread blocks. They increase the flexibility of the tread blocks and improve grip on wet and slippery surfaces by providing additional gripping edges.

The tyre developers combine these elements into a technical structure to achieve the specified tire properties. In a second step, these technical structures are then used by industrial designers to assemble them into a distinctive tread pattern. Continental protects the resulting unique combinations by means of patents. The tyre manufacturer currently holds more than 1,700 granted, active patents for tire tread patterns.

Summer, all-season and winter tyres each feature different tread patterns adapted to their various applications

Summer, all-season and winter tyres each feature different tread patterns adapted to their various applications

Technological evolution: virtual developments and AI-supported performance analysis

While over 120 years ago, the circumferential groove pattern was still carved into the rubber by hand, today Continental designs digital prototypes virtually on a computer using state-of-the-art simulation technology. The initial testing phases are also run as computer simulations.

The experts at Continental are increasingly adopting artificial intelligence. Not only do AI systems analyze large volumes of data that can be used to predict and optimize the physical properties of the tire tread patterns, but they also help simulate the behaviour of tyres under a variety of conditions. New tread patterns are tested and optimized virtually until one stands out due to its performance and is selected for potential serial production. Only then are the first test tyres produced and then carefully trialled at tyre testing facilities. Thanks to virtual development and testing, hundreds of tyres can be saved each year because they no longer need to be physically produced. This helps conserve valuable raw materials.

The requirements for tyires have been constantly evolving for the past 120 years. Today, sustainability plays a key role: the continuous improvement of mileage, wear rate and rolling resistance, without compromising on safety-relevant properties.

Continental's developers also adapt tread designs to new challenges such as changes in climate and legal requirements. Optimized tread and special sipe geometries for improved fuel efficiency and even more driving safety will play a key role in this context.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

18 May 2025

18 May 2025

3992 Views

3992 Views

Ajit Dalvi

Ajit Dalvi