Brose invests in young start-ups, inks pact with AIM3D

AIM3D's new method for additive manufacturing makes it possible for the first time to 3D print materials typically found in automotive series production and accelerates the prototype creation process.

Automotive supplier Brose is acquiring holdings in innovative start-ups. As an investor and strategic partner, the mechatronics specialist says it supports young companies that are actively shaping the future of technology and mobility.

The German company, which is the world’s fourth-largest family-owned automotive supplier, has inked a collaboration with AIM3D which develops new methods for additive manufacturing – and is now benefiting from the long-standing experience and industrialization expertise of the family-owned company.

“Digitization and more closely intertwining markets are rapidly changing our business,” explains Thomas Spangler, Chief Technology Officer Brose Group. “As an investor with a long-term perspective and a strategic partner for promising young businesses our aim is to promote innovation and identify disruptive technologies early on. Thanks to our many years of experience as a system supplier to the global automotive industry with world-class manufacturing expertise we are a good sparring partner for companies that want to successfully present their ideas on an international stage.

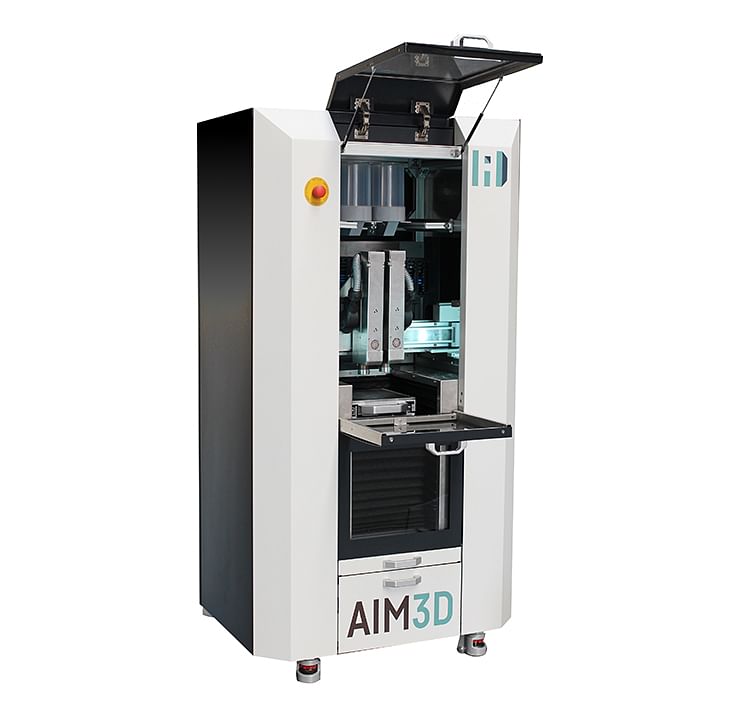

The start-up AIM3D has developed a method which makes it possible for the first time to 3D print materials typically found in automotive series production.

Brose’s first cooperation agreement will be with AIM3D. The Rostock-based company has developed a new method for additive manufacturing. It makes it possible for the first time to 3D print materials typically found in automotive series production. This accelerates the prototype creation process, which in turn speeds up the development of new products and cuts costs. “After welcoming Brose on board we are excited to push ahead with the industrialization of our innovative technology together with this global player,” said Dr Vincent Morrison, managing director of AIM3D.

Brose develops and produces mechatronic systems for vehicle doors and seats as well as electric motors, drives and electronics, among others for steering, brakes, transmissions and engine cooling. Around 26,000 employees at 62 locations in 23 countries generate turnover of 6.3 billion euros. Every second new vehicle worldwide is equipped with at least one Brose product.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

13 Nov 2018

13 Nov 2018

7265 Views

7265 Views

Ajit Dalvi

Ajit Dalvi