BMW’s cell coating line for battery modules goes on stream at Leipzig plant

First of five cell coating lines launched; Leipzig plant to run complete high-voltage battery production process by 2024; in-house production of e-components for the fully electric Mini Countryman

BMW Group Plant Leipzig’s first cell coating line has gone into series operation as e-component production at the site continues to gain momentum. By 2024 the two existing module assembly lines will be complemented by a third, as well as four more cell coating lines and two more high-voltage battery assembly lines. The four coating lines will enter series operation during the course of this year at roughly two-month intervals.

“From 2024 our plant here in Leipzig will be able to run the entire process chain for high-voltage battery production,” said Markus Fallbohmer, head of Battery Production at the BMW Group. “So we will be making an important contribution to the transformation to electromobility.” To meet its goal of fully electric vehicles accounting for at least half of all sales by 2030, the BMW Group is investing more than €800 million to establish and develop e-component production at BMW Plant Leipzig.

More than 2,000 coated cells an hour

Covering 2,300 square metres, the new cell coating system at the BMW plant in Leipzig is located in the former production hall of the BMW i3.

The new coating line can handle more than 10 million cells a year, or over 2,300 an hour. The coated cells are then used on the battery module production line in Leipzig, to make modules for the fully electric BMW i4 and BMW iX1. A further line at the facility is producing battery modules for the BMW iX.

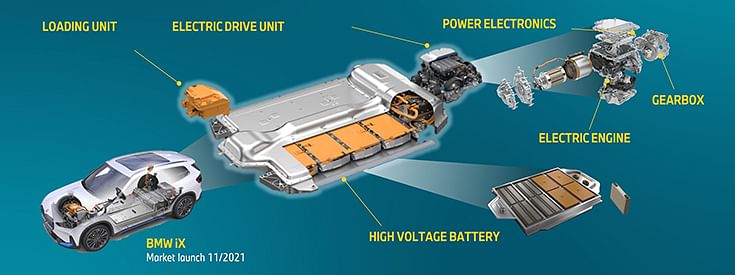

The main components of BMW Group’s fifth-generation electric drive are the electric drive unit and high-voltage battery. It does not contain any rare earths. The high-voltage battery consists of several battery modules, which are interconnected and integrated into the housing.

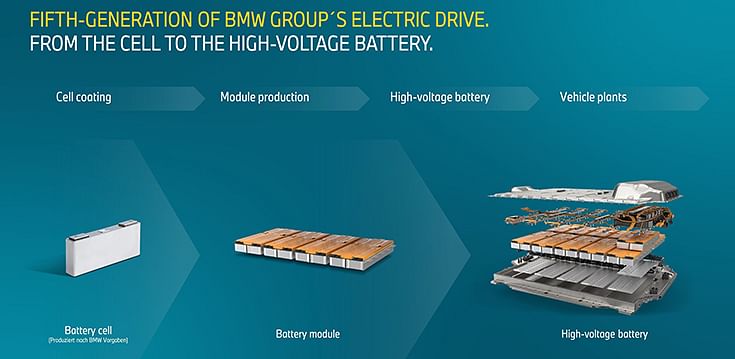

The production system for the high-voltage battery has three autonomous, sequential process steps: cell painting, module production and battery assembly

The production system for the high-voltage battery has three autonomous, sequential process steps: cell painting, module production and battery assembly

High-voltage battery production happens in three stages: cell coating, module production and assembly of the battery itself. The processes are highly automated.

The BMW Group sources its cells from partners who manufacture them exactly to specification. The type that is used depends on the vehicle concerned and is chosen to ensure the best possible characteristics.

How coating of lithium-ion cells happens

Coating lithium-ion cells consists first of pre-treating and patterning their surfaces with a laser. This involves the laser beam ‘chiseling’ a texture into the outside of the uncoated cell to increase its surface area and reduce the surface tension of the aluminium casing. Next, the cells are plasma-cleansed to remove any dirt particles and oxides. Together, these two processes improve the adhesiveness of the surface, ready for the coating to be applied.

It is administered by a specially developed machine that coats the cells in two layers, which are then hardened by UV and offer the best possible insulation for the cells. Finally, a fully automated three-stage quality control process is carried out in which the thickness and surface quality of the coating are inspected. A high-voltage test is conducted to ensure the coating is completely free from defects.

Battery cell coating at the BMW Group Plant Leipzig. Blue chosen in line with positioning of electric BMW i vehicles and as the signal colour of the range.

Battery cell coating at the BMW Group Plant Leipzig. Blue chosen in line with positioning of electric BMW i vehicles and as the signal colour of the range.

The cell coating used at the BMW Group is blue, which was deliberately chosen for its important role in the positioning of electric BMW i vehicles and as the signal colour of the range. Within the BMW Group production network, Plant Leipzig is a pioneer in electromobility, having produced the company’s first fully electric model, the BMW i3, from 2013 to 2022.

Once coated, the battery cells are assembled into larger units known as modules. When completed, these are fitted into a aluminium housing along with the control and cooling units and the connectors that will connect them to the vehicle. The size and shape of the housing and the number of modules inside depends on the vehicle variant. That way, each car receives the most suitable high-voltage battery.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

02 Feb 2023

02 Feb 2023

6479 Views

6479 Views

Ajit Dalvi

Ajit Dalvi