BMW Motorrad develops Automated Shift Assistant to make riding simpler

Automated Shift Assistant’s clever functional design eliminates the need for a hand lever to operate the clutch manually and makes starting, stopping and manoeuvering a seamless affair.

BMW Motorrad has announced development of its new Automated Shift Assistant (ASA), an innovative technical solution that makes riding simpler and more comfortable. According to the company, the riding experience is further enhanced by the automation of the clutch and gearshifting, without sacrificing the emotionally important dynamics of shifting.

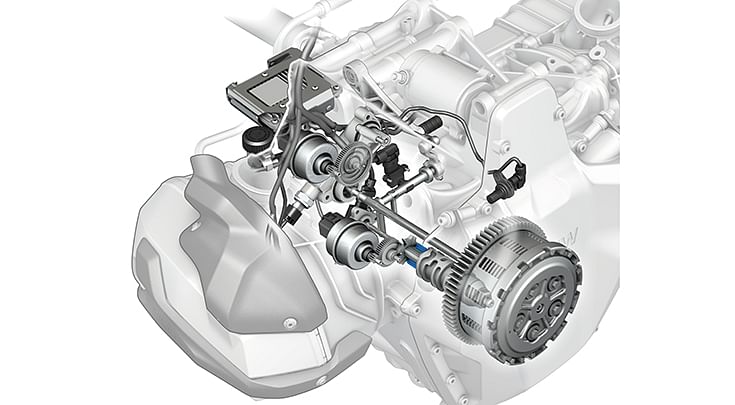

The Automated Shift Assistant features a clever functional design in which two electromechanical actuators automate the clutch and gearshift of the six-speed transmission, which is the main difference to a conventional shift assistant. There is no need for a hand lever to operate the clutch manually. Starting, stopping and manoeuvering are made easy with the Automated Shift Assistant.

Riding with the Automated Shift Assistant also becomes more enjoyable thanks to fast, rev- and load-adapted shift sequences and the resulting precise gear changes. The rider's workload is reduced, which makes riding even more enjoyable. In addition, the Automated Shift Assistant creates an even more direct connection with the powerful boxer engine, as the precise clutch actuation makes it even easier to control the riding experience via the throttle grip and gearshift lever.

The ASA features a clever functional design in which two electromechanical actuators automate the clutch and gearshift of the six-speed transmission.

Benefits of the Automatic Shift Assistant

- Completely eliminates the need for the rider to operate the clutch.

- Dynamic and comfortable gear changes for more riding pleasure.

- Choice of manual or automatic gear shifting.

- Automatically adapts gear shifts to the rider's dynamic preferences in automated D mode.

- Eliminates the possibility of engine stalling due to unfavourable gear shifts.

In 'M' shift mode, gear changes can still be made by foot control, allowing the rider to decide when to change gears.

In 'D' shift mode, the Automatic Shift Assistant really comes into its own. Shift points are automatically selected by the engine control unit. In both ‘M’ and ‘D’ modes, the rider benefits from perfectly executed gear changes with a smooth interruption of traction. The result is efficient motorcycle acceleration and increased riding stability.

In 'M' shift mode, gear changes can still be made by foot control, allowing the rider to decide when to change gears. In ‘D’, the gears are changed automatically depending on the riding mode, engine revs, throttle position and lean angle parameters.

In 'M' shift mode, gear changes can still be made by foot control, allowing the rider to decide when to change gears. In ‘D’, the gears are changed automatically depending on the riding mode, engine revs, throttle position and lean angle parameters.

When shifting up, for example, the jolt associated with a classic manual transmission with a manual clutch is largely eliminated, as is the risk of helmet contact between rider and passenger.

Downshifts are also designed to be as smooth as possible, minimising chassis disturbances. Specific characteristics of the automated shift function are assigned to the different riding modes to ensure perfect shift behaviour in each riding situation. In combination with Active Cruise Control or front collision warning, the networking of functions also brings the future of motorcycling to life.

Electromechanical clutch and gearshift actuators combined with sophisticated electronic controls

The Automated Shift Assistant is the logical and technical evolution of the BMW Motorrad Shift Assistant Pro. Two electronically controlled electromechanical actuators operate the clutch and gearshift, enabling easy starting and automated gear changes. The rider's shift request is transmitted to the control unit via a gearshift lever sensor, which is actuated by the conventional foot-operated gearshift lever. Additional sensors determine the revs of the transmission input shaft and the clutch position. These values are transmitted to the TCU (Transmission Control Unit), which is closely linked to the engine control unit, for modelling and control of the clutch, shift actuation and status.

The clutch is operated by an electro-mechanical actuator combined with a hydraulic system with a direct hydraulic connection between the clutch master and slave cylinders. The actuator regulates the required clutch slip, engages the clutch when changing gear and disengages it when stopping.

In manual shift mode ‘M’, the rider can move the gearshift lever in the desired direction in the usual way. If the revs in the desired target gear are within the maximum or minimum rev range, the shift is made directly. If the engine revs fall below a gear-dependent minimum speed, downshifts are also performed automatically in manual mode. This prevents the engine from stalling.

In shift mode ‘D’ the gears are changed automatically depending on the riding mode, engine revs, throttle position and lean angle parameters. Gears are shifted according to the riding situation and dynamic requirements.

All images: BMW Motorrad

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

06 May 2024

06 May 2024

7247 Views

7247 Views

Ajit Dalvi

Ajit Dalvi