BMW begins production of small-series hydrogen-powered iX5

Research and Innovation Centre’s pilot plant in Munich commences production of technology demonstrator for locally carbon-free mobility in selected regions from mid-2023

The BMW Group is commencing production of its BMW iX5 Hydrogen model. The first ever Sports Activity Vehicle (SAV) featuring hydrogen fuel cell technology has already completed an intensive programme of testing under demanding conditions during the development phase and will now be used as a technology demonstrator for locally carbon-free mobility in selected regions from mid-2023.

“Hydrogen is a versatile energy source that has a key role to play as we progress towards climate neutrality,” says Frank Weber, Member of the Board of Management of BMW AG responsible for Development.

“We are certain that hydrogen is set to gain significantly in importance for individual mobility and therefore consider a mixture of battery and fuel cell electric drive systems to be a sensible approach in the long term. Fuel cells don’t require any critical raw materials such as cobalt, lithium or nickel either, so by investing in this type of drive system we are also strengthening the geopolitical resilience of the BMW Group. Our BMW iX5 Hydrogen test fleet will allow us to gain new and valuable insights, enabling us to present customers with an attractive product range once the hydrogen economy becomes a widespread reality.”

The BMW iX5 Hydrogen is being built in the BMW Group’s pilot plant at its Research and Innovation Centre in Munich. This is the interface between development and production where every new model from one of the company’s brands is made for the first time. Around 900 people work there in the body shop, assembly, model engineering, concept vehicle construction and additive manufacturing. They each work on up to six vehicle projects simultaneously and are tasked with ensuring that both the product and the manufacturing process are ready for series production. In the case of the BMW iX5 Hydrogen, specialists in hydrogen technology, vehicle development and initial assembly of new models have been working closely together to integrate the cutting-edge drive and energy storage technology.

“Production of the BMW iX5 Hydrogen and the BMW-developed fuel cell systems demonstrates our supreme flexibility and unrivalled know-how in the field of small-scale manufacture,” remarks Milan Nedeljković, Member of the Board of Management of BMW AG responsible for Production. “It shows we already boast the necessary expertise for integrating hydrogen technology into the BMW iFACTORY production system as an additional type of drive.”

How the iX5 Hydrogen takes shape

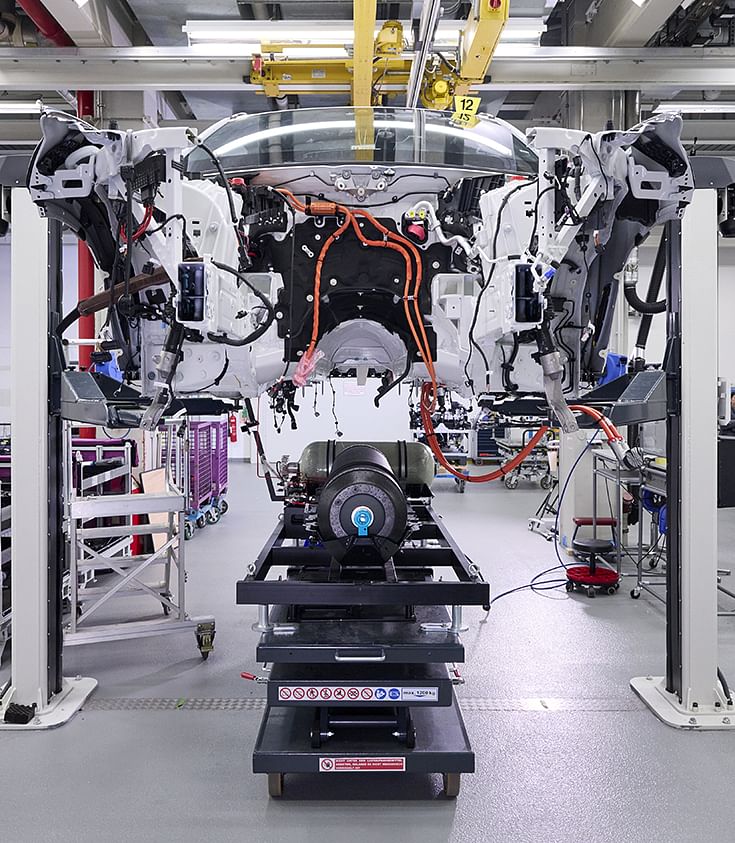

BMW Group Plant Spartanburg in the USA supplies the base vehicles for the hydrogen model, which has been developed on the platform of the BMW X5. They are fitted with a new floor assembly in the pilot plant’s body shop that makes it possible to accommodate the two hydrogen tanks in the centre tunnel and under the rear seat unit. The model-specific 12V and 400V electrical systems, high-performance battery, electric motor and fuel cell are all integrated during the assembly stage, alongside standard production parts.

Positioned in the rear axle area together with the high-performance battery, the electric motor is a product of the current, fifth-generation BMW eDrive technology also employed in battery electric and plug-in hybrid models from BMW. The fuel cell systems located under the bonnet of the BMW iX5 Hydrogen have been manufactured at BMW’s in-house competence centre for hydrogen in Garching to the north of Munich since August this year.

Positioned in the rear axle area together with the high-performance battery, the electric motor is a product of the current, fifth-generation BMW eDrive technology also employed in battery electric and plug-in hybrid models from BMW. The fuel cell systems located under the bonnet of the BMW iX5 Hydrogen have been manufactured at BMW’s in-house competence centre for hydrogen in Garching to the north of Munich since August this year.

Numerous components are produced exclusively for the hydrogen-powered SAV, including some made at the Additive Manufacturing Campus – the BMW Group’s competence centre for 3D printing – which also forms part of the pilot plant. The BMW iX5 Hydrogen passes through all the customary stages of production, starting at the body shop then proceeding to the paint shop and assembly before ending with a final inspection of each individual vehicle. Following this, every vehicle undergoes a comprehensive operational check at the BMW Group’s test centre in Aschheim.

According to BMW, the iX5 Hydrogen combines all the benefits of a locally emission-free drive system with outstanding everyday usability and long-distance capabilities. This makes its hydrogen fuel cell technology an attractive complementary alternative to the battery electric drive system. This is especially true for customers for whom short refuelling stops and long ranges are a must, as well as for regions still lacking an adequate charging infrastructure.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

04 Dec 2022

04 Dec 2022

6664 Views

6664 Views

Ajit Dalvi

Ajit Dalvi