BASF and Hymer develop camper van of the future

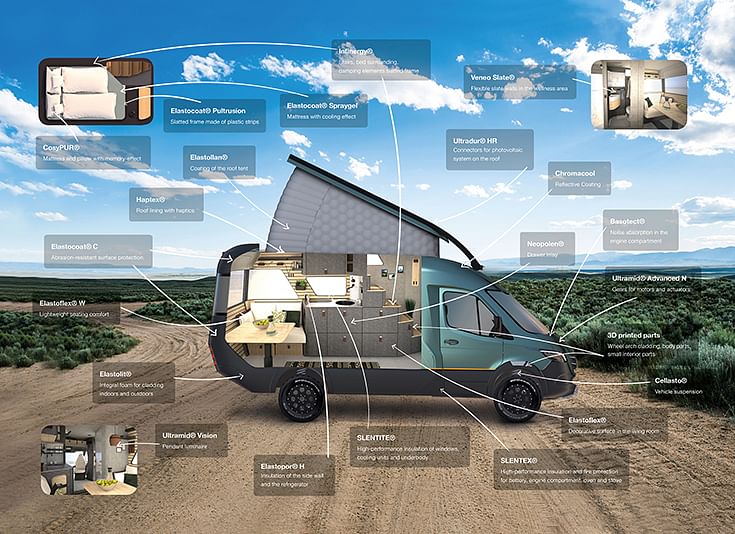

Innovative materials open up new dimensions in lightweight construction and design; more than 20 high-performance plastics enable world’s firsts such as a self-inflating pop-top roof or lightweight natural stone claddings

The VisionVenture, co-created by BASF and Hymer, is a near-production glimpse into the future of van life. Using the development expertise of the BASF Creation Center, a new class of van has been created that is a pathbreaker in lightweight construction, independence, travel experience and design. The vehicle celebrated its world premiere at the Caravan Salon in Düsseldorf, Germany, at the end of August. Now, BASF will present the VisionVenture at K2019 (Hall 5, Stand C21/D21) in Duesseldorf from October 16 to 23.

“Our products give the designers unprecedented new options and functionalities for the VisionVenture,” said Martin Jung, Head of Performance Materials at BASF. “The end result demonstrates the full diversity of our material competence – from inspiration to finished product.”

More than 20 high-performance plastics and a new painting technology from BASF are used in the concept camper. BASF and Hymer have used various innovative lightweight materials and processes in the interior and exterior, providing greater comfort while also making the vehicle more robust. The VisionVenture also sets new benchmarks when it comes to design – for example by combining plastics with natural materials such as hemp and slate. Solutions for energy management, thermal insulation and electrical components, a tailored package of measures for preventing noises and vibrations, and more than 100 3D-printed components round off the vision of modern travel.

“HYMER is synonymous with premium quality, innovation and a sense of discovery. The VisionVenture developed in tandem with BASF perfectly captures these values. It already promises to give our customers an entirely new sense of freedom,” explains Christian Bauer, Managing Director of Hymer GmbH & Co.KG.

Self-inflating pop-top roof a world first

The VisionVenture's self-inflating pop-top roof is a world first and one of the van’s most striking features. It inflates in less than 60 seconds, creating more living space than ever before. The Elastollan coating on the roof creates an outer wall that is resistant to water as well as wind and guarantees a peaceful night’s sleep at a pleasant temperature. The cushions and mattresses in the VisionVenture will also remain pleasantly fresh and cool even on the hottest day. This is down to the temperature-regulating effect of the Elastocoat C Spray Gel, which adheres effectively to all PU foams and can be applied to different mattress surfaces, at different places and in variable thicknesses.

Combining the use of natural stone in interior design with a lightweight approach has never been possible before. But this is about to change with Veneo Slate, manufactured using the compact, non-foamed polyurethane Elastocoat. This world innovation has an exceptionally lightweight thin coating of real slate and with adding just 1 millimetre it is a space-saving and flexible material.

The Elastoflex polyurethane foam offers similar properties. With a unique combination of natural materials and plastic, this equally lightweight material utilizes the structure of hemp fibers to produce cupboard doors and kitchen fronts. Like Veneo Slate, it can be applied to round and curved surfaces, eliminating the need for heavy alternatives like wood or chipboard.

BASF used a range of 3D printing techniques to realise more than 100 components for the interior and exterior of the VisionVenture, including wheel arch linings, bodywork parts, lampshades, handles, hooks and tablet-holders. Whether the components are large or small, hard or soft, carbon fibre-reinforced or transparent, untreated or painted, this digital production method is a fast and cost-efficient solution for individual parts and small batches. The 3D printed wheel arches and other components such as the sills and balcony of the VisionVenture are protected by the polyurea spray coating Elastocoat C, which gives lasting protection from stains, scratches or impact damage from stones.

Sustainable and smart

The VisionVenture sees smart use of materials for energy management, insulation and electric components. For the first time, BASF has combined its two innovative high-performance insulating materials SLENTEX and SLENTITE in the VisionVenture. The solid panel material SLENTITE is used in refrigeration equipment, door panels, window frame profiles and sub-floors. It can be easily cut to size and also provides the required stability for use in off-road vehicles. The highly efficient, safe and space-saving properties of SLENTEX provide heat protection for the battery, engine compartment, oven and hob in the VisionVenture. The high-performance insulating material is very effective in preventing the spread of sparks or fire, thanks to its non-combustible properties. Another advantage: Both materials do not show any effects of aging during their service life.

BASF’s semi-aromatic high-performance polyamides, known by the brand name Ultramid Advanced, are particularly light and strong. The product group has exceptional rigid and solid properties, even when exposed to high temperatures. The polyamides also retain their mechanical stability, making them ideal for use in the engine or engine compartment. Ultramid Advanced T1000 and Ultramid Advanced N are additionally resistant to hydrolysis and there-fore the perfect choice for the pipework in the VisionVenture’s kitchen and shower installations.

Making a statement, inside outside

The VisionVenture makes a strong design statement. A key contributor to the van’s cozy feel is Haptex a polyurethane system for imitation leather, which spans the entire interior. This material feels pleasantly soft and is available in a range of colours and textures. It is also extremely easy to clean and does not contain organic solvents.

The VisionVenture’s outer coating is something else that is new. For functional reasons, camper-vans are usually cream or white to avoid overheating during the summer. With their gray-green VisionVenture, HYMER and BASF are demonstrating that, in future, personal choice can also apply to the paintwork. The paint is based on Chromacool temperature-management technology. Chromacool is available in a wide variety of colors; it reflects the sun’s infrared light, thus reducing the build-up of heat in the vehicle body. This passive temperature management means that heating of the vehicle’s surface is reduced by up to 20deg C, with the inside temperature dropping by as much as 4deg C. Less energy is needed for air-conditioning, which helps to reduce fuel consumption, or to increase the range of electric vehicles.

Meanwhile, to avoid any compromises in comfort on the open road, BASF and Hymer say they have come up with a customized NVH (noise, vibration, harshness) package for the VisionVenture. The compact, microcellular polyurethane Cellasto is used to reduce vibrations and block noise in the interior, drive or chassis. Specifically for off-road adventures, the developers have fitted the VisionVenture with a special Cellasto solution for vibration decoupling and structure support of the chassis, combining driving safety with dynamics and comfort.

Photos: Hymer GmbH

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

10 Oct 2019

10 Oct 2019

18048 Views

18048 Views

Ajit Dalvi

Ajit Dalvi