SKF India's Manish Bhatnagar: ‘Today’s customer is always online, and we want to be where our customers are.'

SKF India’s Managing Director on the impact of Covid-19, key learnings like disciplined cost control and building supply chain resiliency, setting up of an online aftermarket store, capex and new products for electrified vehicles.

SKF India’s Managing Director speaks about the impact of Covid-19, key learnings like disciplined cost control and building supply chain resiliency, setting up of an online aftermarket store, capex and new products for electrified vehicles.

What is the level of the impact of the pandemic on your automotive business?

The automotive industry was already suffering with the sales slowdown in 2019 and the pandemic darkened the outlook further. The initial months of lockdown in 2020 were a bit challenging for us, resulting in a partial shutdown of our manufacturing units. Gradually, business started to pick up again and factories have been running for 24x7.

Currently, for our automotive business that accounts for 45 percent of SKF India's total business, we are focused on gaining share. This is because, for us, automotive is not just one sector. It includes two-wheelers, four-wheelers, commercial vehicles, and tractors among others. The agriculture- linked products, like tractors, have been doing well for the last two-three quarters. Even the two-wheeler segment is performing well. In the passenger vehicle segment, new models are being launched, which did not happen in 2020. In fact, PVs are a very special category where demand and sales are dependent mainly on new model launches and we are seeing that buying has started. The slowdown in CVs started long before the pandemic and is continuing, nothing has changed.

What are the strategies you have deployed to minimise the impact of the slowdown?

In the current context, the pandemic is causing widespread concern and economic uncertainty for consumers, businesses, and communities all over again. First and foremost, we focused on prioritising the health and safety of our employees. Other than that, some of the typical contingency plans we undertook include disciplined cost control to respond well to a challenging operating environment, and built supply chain resiliency, as well as deep customer engagement so that we are able to execute faster on all our strategic priorities.

What is the split between your OE and aftermarket business?

The industrial sector accounts for 55 percent of the SKF India's total business while the rest 45 percent comes from the automotive sector.

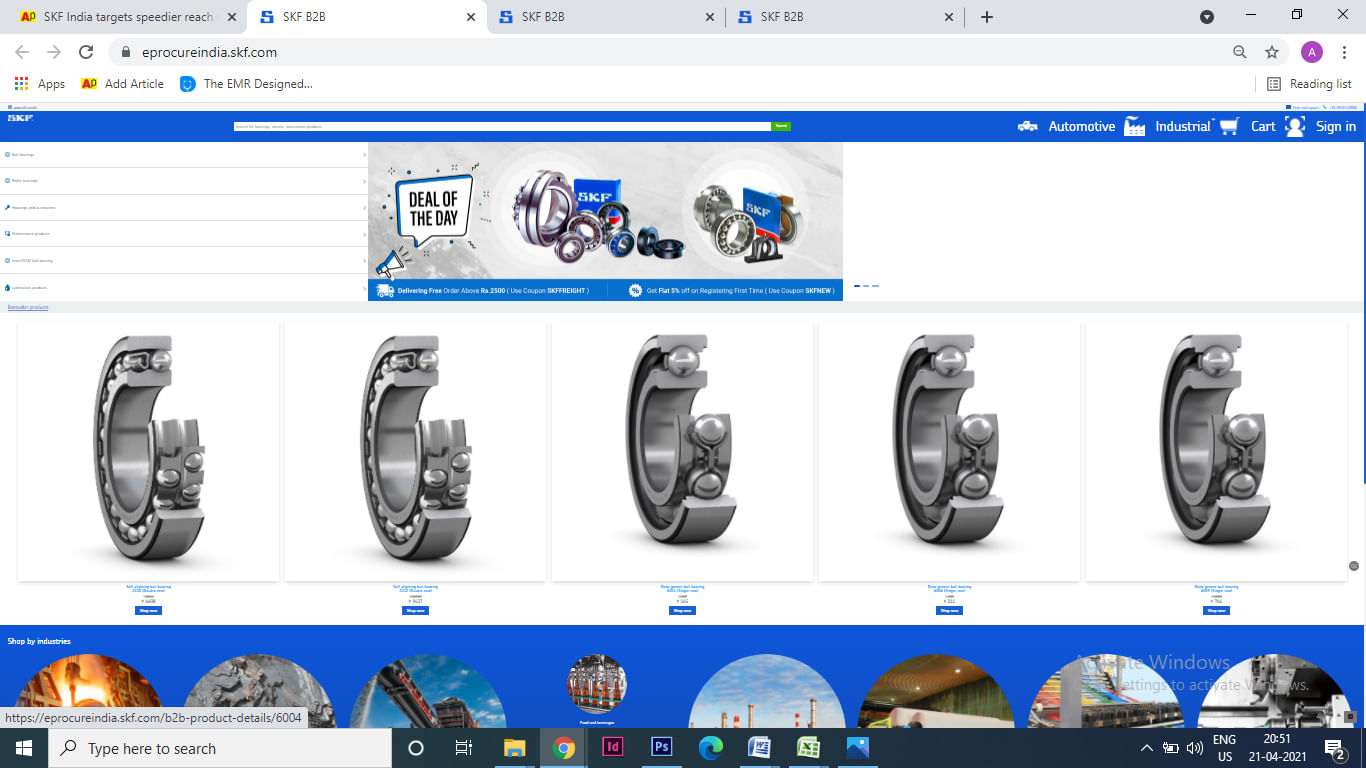

It’s been three months since you launched the e-shop concept in India. What led to the setting up of the Online Store?

The launch is in line with our commitment to expand reach to customers across market segments and continuously providing unmatched customer experience, while further boosting the country’s ‘Digital India’ initiative.

This 24/7 self-service online store aims to provide direct access to SKF genuine and reliable products ranging from Bearings and Bearing Units, Housing and Accessories, Greases, and other maintenance products, for both industrial and automotive segments. All the process industries, MSMEs, traders, retailers, automotive aftermarket retailers, mechanics, and fleet owners will benefit from this wide range of products and solutions.

How has the response been? And what have been or continue to be the challenges?

Currently, we are focusing on putting in place the complete infrastructure, much like most e-commerce companies do — focusing on warehousing and last-mile delivery. So, the last three-four months have been based on looking at the infrastructure setup. The demand has been fantastic, even though it is still three months old. We are enabling infrastructure to enable our customers, be it our channel partners or end-users, to connect with us through digital medium and go ahead with ordering directly on the internet. This would contribute to more than 10 percent of our overall revenue by end of 2021.

What is your geographical reach through the online sales channel?

Our geographical reach is in almost 90 percent of the pin codes in India. We are able to deliver within four hours, once you order a bearing from us, at your doorstep.

What are the new trends in the aftermarket segment that you are currently witnessing?

The pandemic has brought a massive change, globally, in attitudes towards mobility, with health and safety taking utmost priority. Similarly, while the electric vehicle (EV) segment was also hit by the pandemic, its adoption could rise again sooner than later. This means that any technology improvements in propulsion mean more opportunities for the aftermarket.

Even though gas engines remain in the lead, electric and diesel will gain ground. We recently launched our new range of aftermarket products including chain and sprockets for two-wheelers, timing belts for four-wheelers and steering and suspension for four-wheelers, to cater to the changing demands of customers from different sectors across India.

Another major trend is the aftermarket industry leveraging digital and e-commerce technologies to reach out to customers. From using mobile technology to make driving and owning a vehicle easier, to providing technical manuals and other essential information on the smartphones, companies are going an extra mile and building their omnichannel presence to engage customers. We recently introduced our e-commerce portal, that hosts a wide range of products and solutions, and provides a reliable and seamless online experience to our existing and new customers.

The concept of ordering automotive parts online is still new in the Indian market. How do you plan to promote and expand the reach for the same?

Today the customer is always online, and we want to be where are customer are. So, in line with the government’s initiative of ‘Digital India’ we have come up with the unique idea of showcasing our products on the online platform. We want to be the partner of choice for our customers and are committed to creating avenues that support the digital transformation journey for our customers and partners.

Hosting a wide range of products and solutions, the platform provides a reliable and seamless online experience to our existing and new customers. We will be using both traditional and online channels including digital marketing and customer outreach campaigns for creating awareness, promoting its adoption, and expanding its user base.

What are the most popular products being ordered online and from which parts of the country is the online demand coming from?

We are seeing demand from across the country and our fast-moving items are the ones which are in high demand from this channel. Typically, we are seeing small Deep Groove ball bearing and maintenance products where there is a significant interest from potential customers.

Do you also plan to retail products through leading e-commerce websites such as Amazon and Flipkart?

E-commerce enables us to adapt to the changing customer buying preferences and supports our strategy of expanding reach in new markets while growing our presence in the existing segments. At the moment, we don’t have plans to leverage third-party channels to reach out to customers.

Our aim is to create a digital platform for SKF products which is linked to our website so as to give a seamless purchase experience to our customer who visits our website to know more about SKF, products and then decides to purchase the product.

What is your capex plan for FY2022 and beyond? What are the areas that you will look to invest in?

Typically, our capex lies between Rs 100-150 crore, but it is not based on any new factories being set up. So, the capex will continue for machine upgradation, new lines, and channels among others. But it is absolutely very important to look into the possibility of creating a new capacity because the demand is far-far outstripping from what we thought earlier or was estimated.

Those talks are ongoing right now with governments. We will set the companies in the best place at the best investment and of course the best availability of qualified labour.

With the EV segment becoming popular, how do you plan to cater to it?

Electrification is a strong trend in the automotive industry, driven by battery technology development and the multiple benefits that EVs can bring to society, for example, energy security, urban air quality, greenhouse gas reduction and noise mitigation. The growing market of electric and connected vehicles will positively impact our automotive business, as the bearings play an important role in their applications.

By redesigning elements such as the polymer cage, rolling components and using special lubricating grease, for example, customised and hybrid bearings are already solving some of the fundamental issues that can affect reliability in EVs. In terms of electrical discharge, ceramic ball bearings are currently the most attractive solution given that ceramics are typically electrically insulating materials. In addition, ceramic bearings are much harder than steel so last up to 10 times longer, typically requiring less lubrication. Although currently, only around five percent of bearings in EV applications are hybrids featuring ceramic elements, this is beginning to change. The value that hybrid units offer in reliability and the extended service life is becoming increasingly recognised and acknowledged. Overall, SKF has a portfolio of innovative solutions that enable a robust and efficient e-powertrain drive, being the preferred development partner among most of the major OEMs in developing components for automotive electrification.

This interview was first published in Autocar Professional's May 1, 2021 issue.

RELATED ARTICLES

"Connectivity and ADAS will drive the next wave of disruption": Sundar Ganpathi

Tata Elxsi's CTO Sundar Ganapathi on how connectivity, ADAS, and data will define the next wave of automotive disruption...

INTERVIEW- Renault CEO Cambolive: 'India Is Renault' — Targets 3–5% Market Share by 2030

Renault is pursuing a fundamental reset of its India strategy, says brand CEO and Chief Growth Officer Fabrice Cambolive...

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

18 May 2021

18 May 2021

23099 Views

23099 Views

Darshan Nakhwa

Darshan Nakhwa

Hormazd Sorabjee

Hormazd Sorabjee

Prerna Lidhoo

Prerna Lidhoo