'No matter what material is being used, we have the optimisation technology to facilitate lightweighting for automakers.'

Dr Royston Jones, VP (Europe) and global CTO of Altair Product Design on how simulation-driven optimisation technologies can enable carmakers to identify where material can be removed to hit weight and performance targets.

Dr Royston Jones, the vice-president — European Operations and global chief technology officer of Altair Product Design, Altair’s consultancy business of more than 800 designers and engineers worldwide, on how simulation-driven optimisation technologies can enable carmakers to identify where material can be removed to hit weight and performance targets.

How do you perceive the lightweighting trend as an inevitable requirement by all global automakers across the vehicle and component platforms?

Lightweighting is always going to be a trend as lightweight is equivalent to fuel efficiency. It’s never been more important to make sure that you’ve got as light a vehicle as possible, provided that it satisfies all your structural targets. The question has become more about the best methods to take weight out of vehicles rather than whether it’s the correct thing to aim for.

From our point of view, using less material must go hand-in-hand with using lighter materials to ensure that you are maximising your return of engineering investment. That’s where Altair’s optimisation technologies come in, enabling carmakers to identify where material can be removed to hit weight and performance targets.

The massive trend towards electric vehicles is also facilitating lightweighting as you again have efficiency targets to meet and there’s a requirement to offset the weight of the batteries. In 10 years, we may live in a world where there are not many petrol engines around, considering the speed at which things are changing at the moment.

How can Altair software solutions contribute to weight reduction requirements in the early stages of product development?

Simulation-driven design philosophy really is something that’s possible with Altair Solutions. We have been promoting that for more than 30 years now and at the core of that philosophy are industry-proven design optimisation technologies and methodologies. But as well as that, it’s linking the technology up with advanced materials. So no matter what material is being used – steel, aluminium or composites – the optimisation technology is there to facilitate it.

Of course, the technology has its biggest impact in the early stages of product development where the cost of change is at its lowest. Finding you have weight or performance challenges late on in the design programme leads to substantial costs to correct it. So allowing optimisation technology from Altair to guide the design process and inform the design teams with practical and timely feedback is essential.

Last month, I attended an internal meeting of over 70 of our optimisation experts from around the world. I think that gives a flavour of just how much Altair’s commitment is to not just the development of intelligent technologies but the investment in the people and experience in deploying the tools on real world vehicle platforms.

Altair assisted SAIC Motor, the largest domestic motor manufacturer in China, in bringing a new range of vehicles to market in an aggressive time frame – just 12 months – while meeting European requirements. The Roewe 550 automobile formed the basis of this project.

The newly established SAIC UK technical centre (SMTC) worked closely with both the China and UK arms of Altair ProductDesign to utilise its engineers’ skills in vehicle development and analysis. Specifically, Altair ProductDesign was made responsible for the crash, NVH and durability performance of the Roewe 550.

A key factor to achieve the tight time scale was the successful implementation of a simulation design driven process and optimisation techniques to minimise cost and weight while maintaining performance. Customised process automation techniques were used routinely throughout the program to keep the overall development on track.

During the Roewe 550 development, SMTC UK and Altair ProductDesign engineers produced a virtual design of the vehicle within just 12 months that required no full prototype testing while simultaneously reducing vehicle mass.

As a result, the vehicle was delivered on time, met all performance objectives and is now on sale in China. Thus, SAIC with Altair ProductDesign successfully demonstrated that aggressive vehicle program time scales can be met through effective use of a simulation-driven design process combined with the optimisation technologies.

Altair has helped Renault achieve substantial weight savings in the development of its global engine platform(s). Can you throw some light on how the weight savings were achieved?

At Renault, the weight saving was achieved largely through the application of Altair’s design optimisation solution, OptiStruct, along with our product design team, to identify where the material within the structure – not just the engine block – could be removed without impacting performance.

Which Indian OEMs and component suppliers are currently working on weight reduction jointly with Altair?

We have over 100 auto OEMs and suppliers working on weight reduction / lightweighting projects using Altair OptiStruct technologies. Material and cost savings in the range of 10-30 percent have been observed on different automotive components and systems.

Which specific areas are the most common in vehicles and components from where weight reduction is achieved? Also, on the flip side, which are the most unconventional areas from where weight savings can be achieved?

It’s really across the whole vehicle but if you want to make the biggest impact, then OEMs are targeting the areas where they have the most control over which is the body-in-white structure. Depending on what the structure is, you can make some really significant savings here, like 20-30kg from a body in white.

On the component level, it could be 1kg or less. For me when someone says what should you aim for, I would say aim for something big as that’s where you’ll get the return on your investment but really it’s across the board – powertrain, components and closures.

I wouldn’t say there are any areas I’d consider to be unconventional. It’s really a virtuous circle. When you start saving weight from one area, then maybe it affects your powertrain meaning it can be downsized which leads you to look at weight again.

With BS VI emission norms kicking in by 2020 in India, it is estimated that average vehicle weight will rise due to additional fitments. How can OEMs and suppliers counter this challenge?

Lightweighting is becoming more important due to the new emissions requirements for, which has created a need to remove weight and reduce emissions. There is still a lot more work and research that is needed to be done before the industry is ready to meet the BS VI emission standards. Lightweighting is only one important contributor: powertrain, drivetrain development need to be taken into account as well. Everything needs to play a role in meeting the standards.

An added appeal of lightweighting is that lighter cars handle better and will only improve consumer acceptance provided all other attributes are maintained (such as safety, stiffness and noise/vibrations).

How is Altair gearing up to address new technological requirements globally such as electric vehicles and hybrids, battery cooling and several other areas?

Altair is really well prepared to meet these news technologies. Most of the work we’re doing in Europe now for optimisation projects is being done on electric vehicles and hybrids where you can have different vehicle architectures. Rather than having conventional architectures, you can use optimisation technology to help define what those efficient new structures should be.

Altair has also invested heavily in electromagnetic simulation technologies in recent years following the acquisition of FEKO and Flux.

Can you highlight some upcoming trends in simulation and software which can help automakers lightweight vehicles and components?

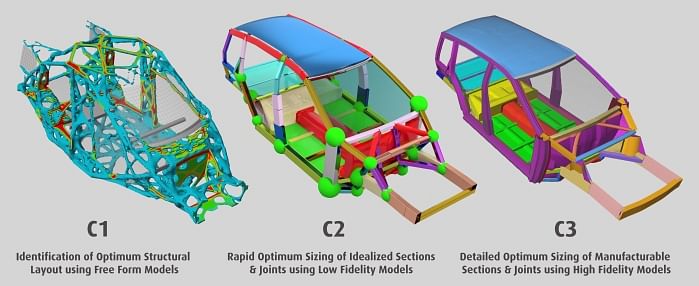

We are seeing many new trends in simulation to assist in lightweighting, largely around processes that facilitate the use of optimisation early and throughout the development process. A good example is Altair’s C123 process. Traditional simulation (CAE) often isn’t quick enough to deliver the required design direction at the early stage of vehicle design.

C123 is a unique three-stage concept development process that makes use of optimisation techniques to rapidly explore design variations. Each of the C123 stages deploys optimisation technology, providing the designer with structural data relating to the mass and attribute performance consequences of various design decisions and facilitating target ‘trade-offs’.

Altair's C123 is a combination of optimisation technologies, design processes and engineering expertise that enables companies to increase the maturity of designs.

We are also seeing a move towards the use of multi-disciplinary optimisation (MDO) which has been facilitated by the explosion in computing power we’ve all witnessed in recent years. Altair has developed the tools and processes to take multiple attributes into an optimisation problem at the same time.

I would also say that designing with robustness in mind is key as you are designing close to the wire and you have to make sure you are the right side of that target. I expect us to be doing more and more of this type of work.

Do you think OEs in the Indian market are leveraging the advantage of simulation for lightweighting to the fullest yet? And what are the challenges to growth in India?

I don’t believe this is being fully leveraged in Europe although it is hard for me to comment on India specifically.

Having good proven solutions like OptiStruct will obviously help, combined with leveraging hi-performance computing. However, largely the ease of adoption is dependent on competency building, confidence and most importantly an optimisation-enabled simulation-driven design becomes part of vehicle design/development process.

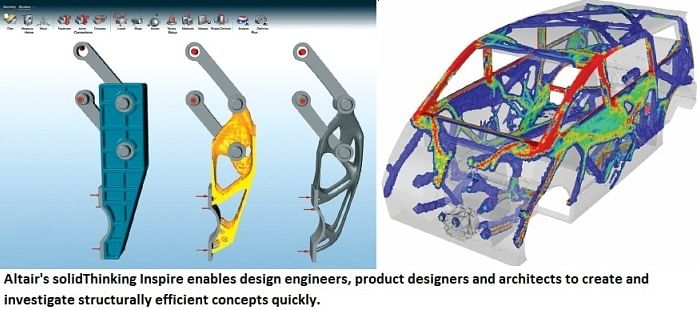

We have a dedicated product design//consulting and application engineering team in India with optimisation skills and expertise in implementing these solutions in the automotive segment. They help our customers implement our optimisation and simulation-driven design technologies – OptiStruct, HyperStudy as well as Inspire – in their daily work or specific lightweighting projects that they are implementing.

We are also trying to roll out the ‘Optimisation Center’ concept which has proven very successful in Europe and the US to India and the rest of Asia. The Optimisation Center operates as a focused ‘skill centre of excellence’ where a group of optimisation experts collaborate within an organisation to apply technology to develop lightweight, performance optimised designs for a wide range of product components and structures.

On a related note, we are also trying to seed basic interest and tools skills for optimisation technologies in budding engineers via our free Engineering Student Contest – AOC India. We are in the sixth year of this contest and we have, on an average, over 1,000 engineering students participate in this contest every year.

What are the latest developments in bio-mimicry to achieve major gains in the automotive space?

For me, it’s more about the relationship with manufacturing processes. If you have manufacturing processes that are more aligned to topology optimisation such as additive layer manufacturing, as well as others like hollow castings, then it really facilitates the use of organics, highly efficient designs.

This interview was first published in Autocar Professional's November 1, 2016, Lightweighting special issue.

RELATED ARTICLES

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

TVS Celebrates 20 Years of Apache, Eyes Premium and Global Push

Marking two decades of its flagship performance brand, TVS Motor unveiled special anniversary editions on Saturday while...

Q&A: Mahindra's Nalinikanth Gollagunta on Upcoming Festive Season, 'Bold' Design Choices

Automotive Division CEO Nalinikanth Gollagunta says mid-teens growth is achievable with Roxx ramp-up, BEVs, and a resil...

By Autocar Professional Bureau

By Autocar Professional Bureau

14 Nov 2016

14 Nov 2016

76476 Views

76476 Views

Prerna Lidhoo

Prerna Lidhoo

Darshan Nakhwa

Darshan Nakhwa