'BS IV will be the inflection point for AMT usage in commercial vehicles in India.'

P Kaniappan, Wabco India’s MD on why upcoming BSIV norms are the ideal platform for for its new products, how mandatory ABS fitment in CVs is a huge business opportunity for the company, and connectivity as a growth driver.

P Kaniappan, Wabco India’s managing director on why upcoming BS IV norms are the ideal platform for for its new products, how mandatory ABS fitment in commercial vehicles is a huge business opportunity for the company, and connectivity as a growth driver. An interview by Kiran Bajad.

How do you view the current market position and the demand-supply situation?

The market has become uncertain due to several things and it’s extremely tough to predict the future. We work on a calendar-year basis and the first two quarters of 2016 were better as the industry was growing at over 20 percent.

In the third quarter, there was a major correction largely due to heavy rains in North India, distress in the construction segment, and also replacement demand slowing down. October onwards things were improving but with demonetisation, the market will be impacted.

While vehicle production is continuing, there has been an immediate impact on aftermarket sales; it will be a few months before things return to normal. To offset the domestic slump, we are focusing on the neighbouring countries and managing through exports in the aftermarket. In India, we are reaching out to STUs and OES to fill the dip in aftermarket sales. I believe this impact is a short-term one of a couple of months.

Wabco is a technology leader in commercial vehicles globally. What are the technologies you are working on for the Indian market?

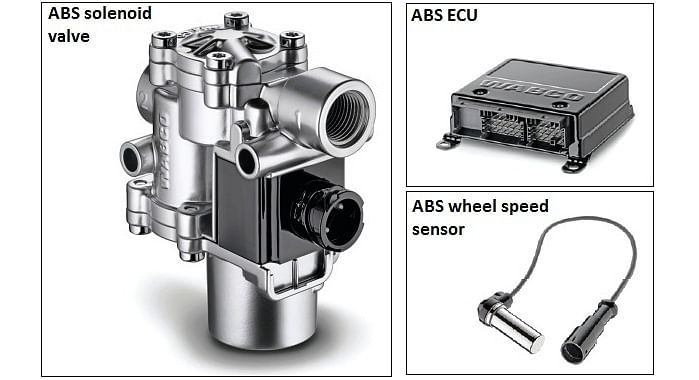

There are several things we are working currently in India. The turning point was mandatory fitment of Anti-Lock Braking System (ABS) for the domestic market, which has opened several opportunities for us. Along with it, BS IV (from April 2017) is the best platform to bring most Wabco products to the Indian market. This is because an electronic engine with an ECU helps make the entire vehicle intelligent. This year, our theme at IAA 2016 was ‘Mobilising Vehicle Intelligence’.

We are trying to make the whole system intelligent. We are trying to leverage ABS beyond driving safety and are trying to help customers gain certain values in fuel efficiency. We have also launched Electronic Control Air Processing which helps save fuel. Secondly, ABS comes with a hill assist feature or anti-rollback type, which ensures a truck parked on an incline does not roll back; it will be launched in India soon. The third product is Electronic Stability Control, a rollover protection currently being homologated on vehicles. Our focus is ABS as it is now mandated with almost all vehicles. We aim to provide value to customers, leveraging this investment made by them.

On the safety front, there is a collision mitigation system and autonomous emergency braking. This product, which will be launched with some customers, monitors the vehicle using a radar and camera system for moving and stationary objects in front and alerts the driver. In India, most accidents take place in the wee hours of the morning when the driver is not alert; this will help alert the driver through vibrations or acoustic alarms. At IAA 2016, we launched the 'OnGuardMax' advanced emergency braking system and are working with some customers.

BS IV emission norms will come into effect from April 2017. What impact do you foresee from this regulatory decision by the government?

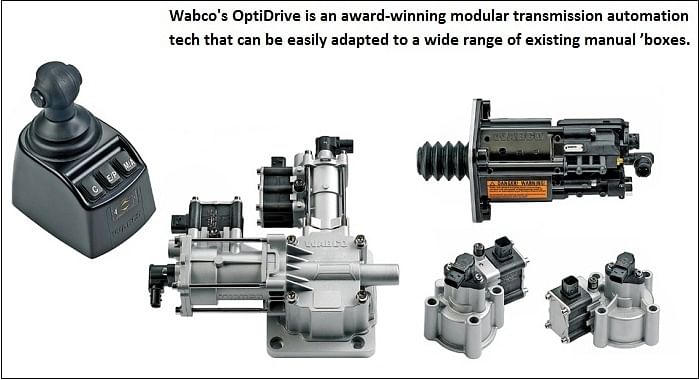

BS IV is going to be complementary for several of our technologies. For example, with electronic engines, we are bringing some of our other products like Automated Manual Transmission (AMT) which need electronic engines.

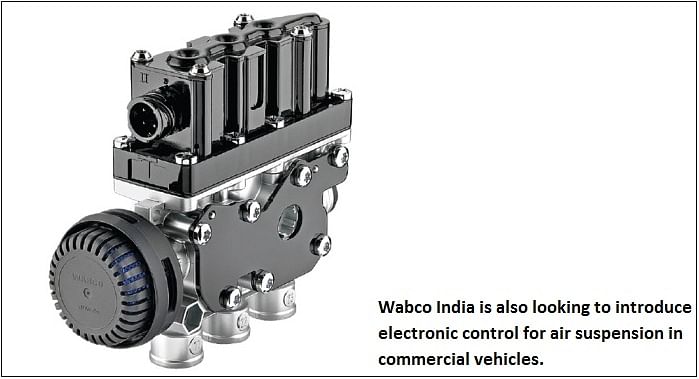

BS IV, we believe, would be the inflection point for AMT penetration in the Indian market. All the major OEMs in India are getting ready with AMT in their products and this is another focus area for us. Besides this, under the UBS-II specification for buses, in the front axle, an air disc brake is required as per the specification. We have homologated our disc brake with key OEMs and foresee an opportunity for this product too. On the suspension side, we are focusing on penetrating Electronic Control for Air Suspension (ECAS) which has many functions like kneeling and monitor load on the axle, among others.

We have recently launched our automatic slack adjuster with key OEMs. This is our global product design for a long-life, sealed and dust-free superior product with which we are looking to penetrate the Indian market along with other products like tyre pressure monitoring, both for the aftermarket and OEMs. We have also launched fleet management solutions, leveraging our strong global product portfolio.

Wabco has been working on several technologies for the CV segment. What is the market response and what are the challenges?

The market trend is good if the payback is faster. That is the approach we have adopted with efficiency or fuel savings as we constantly look at the faster payback to our customers. As regards the safety aspect, there were challenges but now even the government is serious and most of these things have to come through the regulatory route.

Along with safety and fuel efficiency, connectivity is a focus area for Wabco in India. Can you elaborate further?

Connectivity, to start with, is about having a communication unit in each vehicle which will ‘talk’ to neighbouring vehicles — firstly from truck to trailer, then vehicle to vehicle, and finally vehicle to environment. This is going to be the future with fleet management solutions. We have already built our capabilities in this area, which will be leveraged further.

As regards ABS, do you see cost as a constraint? How are you engaging with customers?

Customers are highly informed but the key point is that they always want to see the payback period. Even after making ABS mandatory, an entry is difficult unless it is made viable for the truck operator. Therefore, today, with fully localized ABS including the electronic parts in India, we are now well placed to cater to the demand that will come. We were preparing for this mandate for quite some time.

How do you see the response for ABS in the aftermarket segment?

We have equipped nearly 50,000 trucks with ABS and made them safer through the retro-fitment route. Considering there are over two million trucks in India, we have a huge opportunity. Apart from safety and efficiency, connectivity is another theme we are working on and fleet management is part of it. Thus far, we have sold close to 3,000 fleet management solutions in the aftermarket. Initially, our offering was basic vehicle tracking solutions but now we are coming up with advanced solutions for fuel monitoring.

Wabco has been engaging with the CV industry for AMT, especially in buses. Given that BS IV is coming, will AMT gain acceptance in trucks?

AMT is applicable for buses and trucks because the whole idea is to simulate the best driver which directly helps in improved fuel efficiency and comfort. This product helps the operator make money and still enjoy better comfort. While it calls for some investment, the payback period is not more than one year as we are able to demonstrate 3-5 percent fuel savings. We are now at an advanced stage of maturity with this product. We launched AMT on buses two years ago. With ABS and electronic engines coming up due to BS IV, we see AMT gaining traction (in India).

Wabco has bagged an order from Mahindra & Mahindra for vacuum pumps for passenger cars. Are you looking at growth opportunities in this segment?

Till date, we have not been playing a major role in the Indian passenger car segment. However, globally, we are quite strong in vacuum pumps. We were already supplying to one global passenger car OEM in India. The product is largely used in mid- and high-end cars for diesel engine application. We now foresee a big opportunity to strengthen our position in the passenger car segment.

Apart from vacuum pumps, we also have electronic control for air suspension for highend cars with high market share globally. These products are now manufactured in India and exported and will be made available to Indian customers. Given that India is predominantly a small car market, this product will take some time to come in India. At present, our focus is to drive vacuum pumps penetration in the market.

In August 2016, we received a significant order from Mahindra & Mahindra with a major share in vacuum pumps. We will start supplies with a fully localised product next year. To be a serious player in the passenger car segment, you have to localise and become cost competitive. We will also start talking to other customers for this product. However, our passenger car business will remain small and our major focus continue to be the commercial vehicle market.

How relevant are autonomous trucks in the Indian context?

India is a relevant market for this technology although there is not one environment or situation everywhere. We do have traffic issues but there are select applications where there could be possible applications. For example, mining is where autonomous driving can help or support the driver in certain applications. Having said that, autonomous driving has stages. My understanding is that it’s not a driverless situation that everyone is looking at it immediately and that could be away 20-30 years from now. At present, it is an extension of driver assistance. It will definitely come to India and I see some customers keen on it.

What are your growth projections for Wabco India’s business in the near term?

We see India as a growth market and for the long term we have a very positive outlook about India’s potential. That is the reason why we have been investing in India, both in terms of manufacturing footprint and engineering capabilities. In the short term, there will some hiccups but our focus is long term.

We want to make India a centre of excellence for engineering and manufacturing. We have steadily increased our manufacturing footprint, and on the engineering side we have almost doubled the headcount in the mechatronics side in the past five years. On the software side, we have grown at least three times. Most of the software that we write in India is for our global requirements.

This feature was first published in Autocar Professional's 12th Anniversary issue. Subscribe to our magazine to get exclusive news, features and analysis.

RELATED ARTICLES

"Connectivity and ADAS will drive the next wave of disruption": Sundar Ganpathi

Tata Elxsi's CTO Sundar Ganapathi on how connectivity, ADAS, and data will define the next wave of automotive disruption...

INTERVIEW- Renault CEO Cambolive: 'India Is Renault' — Targets 3–5% Market Share by 2030

Renault is pursuing a fundamental reset of its India strategy, says brand CEO and Chief Growth Officer Fabrice Cambolive...

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

By Kiran Bajad

By Kiran Bajad

07 Jan 2017

07 Jan 2017

14747 Views

14747 Views

Darshan Nakhwa

Darshan Nakhwa

Hormazd Sorabjee

Hormazd Sorabjee