ZF walks the tech talk to become future-proof

The company is also sharpening its India focus as the local team gets autonomy and direct access to the Germany-based HQ.

Global automotive component and technology major ZF Friedrichshafen AG draws up new strategy to become a full systems supplier and tap into the opportunities around vehicle motion control, automated driving, electric mobility, integrated safety and digitisation.

Mega suppliers appear to be making the most of disruptive times. They are joining hands with key technology providers, defining what future solutions may look like, and are also embracing start-ups while consolidating their capabilities across the spectrum. To sum up, they are strategically becoming indispensable.

ZF and Faurecia-developed Trendsetting Cockpit concept, which is for fully automated vehicles (Level 4) without a steering wheel and pedals.

The mega-suppliers have a solid financial base, can quickly build plants closer to their customers around the world, invest more in R&D every year, support high-volume and modular vehicle platforms, and transfer or share technologies across continents in no time. While these companies already build the most critical parts of vehicles, they are set to play an even bigger role in the future of mobility.

ZF Friedrichshafen AG, one of the world’s largest automotive suppliers from Germany, is aggressively working to become a full systems supplier as it prepares itself for the new emerging mobility trends.

Hyderabad-based Technology Centre is one of the ZF Group's important seven global tech centres. The rapidly expanding unit is contributing to the development of ZF's ambitious ProAI supercomputing system meant for futuristic self-driving vehicles.

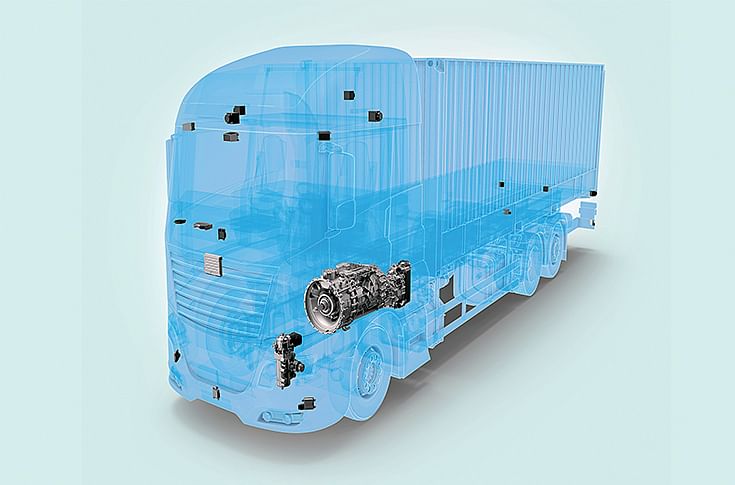

The 36 billion euro (Rs 288,658 crore) company has drawn up a clear roadmap anticipating opportunities around four emerging domains in the future of mobility – vehicle motion control, automated driving, electric mobility and integrated safety. ZF has set digitisation and Internet of Things (IoT) as the overarching theme for these domains, highlighting IoT’s central role in the development of system solutions of the future.

The company has several engagements – all prepping it up for the future. ZF has joined hands with French component major Faurecia to develop a trendsetting cockpit for autonomous vehicles. It has also entered into a collaboration with Germany’s Hella to focus on sensor technology such as front camera systems, image recognition and radar systems. It is working with Nvidia to develop a supercomputer platform (ZF ProAI) touted to be the heart of autonomous driving. ZF has 40 percent shareholding in doubleSlash – a software company, which is developing vehicle-networking architecture. It also has a 45 percent share in Astyx, which is developing radar technologies.

L-R: Dr Gunther Schuh, founder and CEO, e.GO Mobile AG and ZF CEO Wolf-Henning Scheider. The two companies have formed a JV called e.GO Moove GmbH, which will begin production of the people-mover in 2019.

On the other hand, ZF’s stake in ibeo provides it access to mobile lidar sensors for three-dimensional recognition of the vehicle surroundings. It is also working with UBS and IBM to develop a transaction platform (Car eWallet) that vehicles can use to pay independently. ZF is also working with China’s Baidu for developing solutions for autonomous driving and telematics specifically for the Chinese market.

And, most recently, ZF has invested in Aachen-based (Germany) e.GO Mobile AG. The latest joint venture, named e.Go Moove GmbH, plans to manufacture people and cargo movers targeting the urban mobility requirements of the near future. The people/cargo movers will be electric vehicles meant to be eventually driven autonomously. However, to start with as early as 2019, these vehicles will be manually driven with some level of autonomous tech. With its latest venture, ZF appears to have strategically repositioned itself as a supplier of complete logistics solutions.

In summary, all these efforts put together define ZF’s approach to its overarching goal of Vision Zero – mobility with zero accidents and zero emissions.

ZF's growth Roadmap for India

While the mega supplier’s new strategy involves gearing up for the future mobility requirements first anticipated across the developed markets, it also lays down a clear roadmap for developing countries such as India.

According to the company’s latest annual report (2017), the Asia-Pacific region, which counts China as the core market, contributed 21 percent of its global business.

Built on a scalable platform, the e.Go Mover is a production-ready vehicle that features ZF's electric drive, steering systems, brakes, ProAI central computer and sensors for automated driving. ZF expects demand for e.Go Mover (cargo+public) vehicles to reach one million units in 5-7 years.

According to Wilhelm Rehm, head – corporate materials management, commercial vehicle technology and industrial technology at ZF, “Asia Pacific is divided in China, India and the rest of Asia for us.”

The German company, which recognises India as a unique market – and very different from the other global markets – looks to capitalise on the opportunities arising out of the new regulatory measures (BS VI emission norms, safety mandates, GST) and improving infrastructure, besides consolidating its existing strengths.

Fredrik Staedtler: "With the recent developments in the Indian market including GST, we see a big opportunity for stronger TCO-driven decision making."

In order to make its India setup more agile than ever before, ZF has lent autonomy to its local management team thus giving it direct access to the Germany-based HQ.

It is closely watching the Indian economy, which will make airbags mandatory for all passenger cars from October 2019, will open up for BS VI emission norms from April 2020, and also has plans under discussion to replace a large fleet of commercial vehicles (and other passenger vehicles) older than 20 years from the roads with the new ones.

While it is holding regular discussions with OEMs and planning capacity expansion for airbags and seatbelts, the senior management at ZF expects the truck market to evolve to automatic transmission systems after the implementation of BS VI norms in the Indian market.

Wilhelm Rehm: "The major step is BS VI from 2020. With that, you would need higher efficiency on the drivelines. We hope the market will upgrade from MT to ATs."

Speaking to Autocar Professional in end-June, on the sidelines of the ZF Technology Day 2018, Rehm, who is also a member of the Board of Management at ZF Friedrichshafen AG, said, “The major step is BS VI from 2020 in India. With that you would need higher efficiency on the drivelines. We hope that this will help the market upgrade from manual transmission systems to the automatic transmission systems. We are trying to be ready for that.”

“We have major plans on how to grow in China and in India. Therefore, we are trying to build up the resources in the region and for the region. In China we have built up an engineering centre in Shanghai. China is a major truck market and, therefore, we started working on a JV with Foton. In India, our focus is on the Pune facility, which is owned by ZF. Inaugurated in 2015, the Pune plant has enough area for future expansion. Also, our seatbelt and airbag business is very important for us. We are seeing this opportunity in India (mandatory airbags). We are having many discussions with our OEM customers and we are able to fulfill the need in the Indian market. However, given the cost pressures, we plan to optimise costs via large-scale manufacturing,” elaborated Rehm, while giving details on the region.

ZF Innovation Truck deploys intelligent mechanical systems, sensors and control units to see, think and act.

Rehm credits Indian prime minister Narendra Modi, who had visited Hannover a few years ago, for the cumulative increase in the exports from ZF India. “When PM Modi spoke about the Make-in-India initiative at the Hannover Fair a few years ago, it gave us a direction to boost our export of parts from India,” he added.

Earlier this year, ZF India achieved cumulative exports of parts worth 100 million euros (Rs 802 crore). The company has now doubled its target to 200 million euros and plans to achieve it within the years to come.

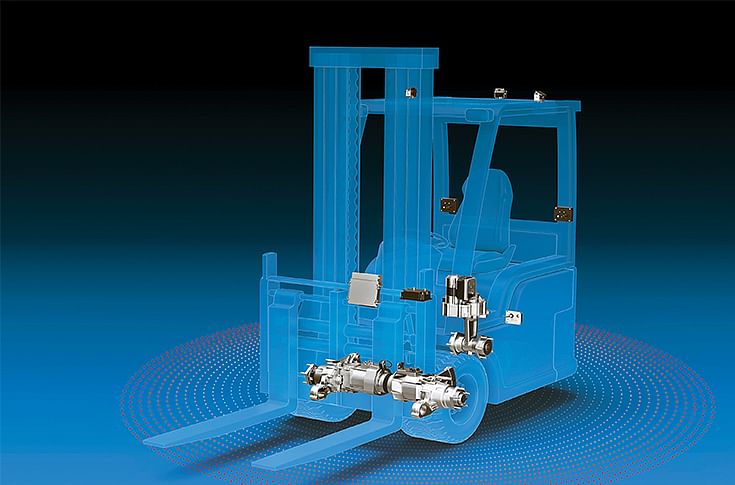

ZF debuted its innovation forklift, which autonomously and electrically drives itself offering material handling applications. It Is a part of ZF's Model Factory concept

“The target is to have a secured supply chain from India. We have installed a purchasing hub in India; we have purchasing people in Hyderabad, Pune and in Coimbatore. We have aligned this purchasing hub directly to Europe, and we are having a lot of discussions with our Indian suppliers. For us, India is a very important market. In a number of cases, we have delivered parts from India to the US, Germany and to the other locations as well,” disclosed Rehm.

Localisation of transmission and chassis systems

Fredrik Staedtler, the executive vice-president, Head of Commercial Vehicle Technology Division at ZF, is particularly keen on the total cost of ownership or TCO-driven decision-making in the Indian CV industry. He applauds GST and estimates that it, along with the fast-improving infrastructure, will result in the longer uptime for trucks.

ZF EcoShift six-speed manual transmission for buses is a flexible basic transmission that can be extended on a modular basis depending on requirements.

“We are very excited about the development of the Indian market. In fact, with the changes that have happened recently in the past 12-24 months including the GST, we see a big opportunity for stronger TCO-driven decision-making process. This, in our opinion, will provide a lot of opportunities to ZF technologies. In India, we will increase our footprint in the six-speed and nine-speed manual transmission systems. We will work with the supply base as well to increase our production capacities. This will be the first step where we will see automation of the transmission systems. On the chassis side, we have plans to localise our chassis components such as shock absorbers. So there are various aspects of chassis and drivetrain that you will see localised in our Pune plant,” revealed Staedtler while sharing plans on India.

Fast-growing tech centre in Hyderabad

ZF opened a Technology Center in Hyderabad in March 2017 in order to support its local and global projects utilising India’s global reputation for software development. This modern facility now has a large team of over 1,000 engineers working together to fuel ZF’s global ambitions. Interestingly, this talent pool is also contributing to the ZF ProAI supercomputing system meant for autonomous vehicles. The company plans to double this headcount within the next couple of years.

ZF ProAI is an artificial intelligence-based supercomputing system developed jointly by ZF and Nvidia.

ZF operations in India are spread over 28 manufacturing plants including five joint ventures and two aftermarket sales and service centres. Given the pace of global megatrends like connectivity and safety, as also autonomous driving, globally and also in India, expect ZF to continue to make strong moves here.

(This article was first published in the 15 July 2018 issue of Autocar Professional)

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

12 Sep 2018

12 Sep 2018

10251 Views

10251 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi