Tech Talk: Nissan's X-in-1 powertrain narrows ICE-EV cost gap

Nissan's electrified drivetrains use compact motors and parts sharing to reduce EV development cost.

Although EV sales are on the up, there’s a yawning price chasm in most cases between them and their ICE counterparts.

So far, some manufacturers have relied on the power of their brand or slick design appeal. But apart from MG, there’s been little evidence of the industry as a whole trying that hard-to-reach cost parity with conventional models.

Thankfully, that mindset looks to be shifting with news that Renault is physically testing its CMF-B platform with nine mules. It will form the basis of the new Renault 5, which looks fabulous. But, more importantly, the platform is 30% cheaper than the outgoing Zoe to make.

Renault isn’t alone. Nissan announced in March that its new ‘X-in-1’ powertrain packages will reduce driveline costs by 30% by 2026 compared with 2019. It also expects to achieve price parity between its hybrid e-Power models and conventional ICE models by the same date. Parity for EVs will come “eventually”, helped by the introduction of solid-state batteries.

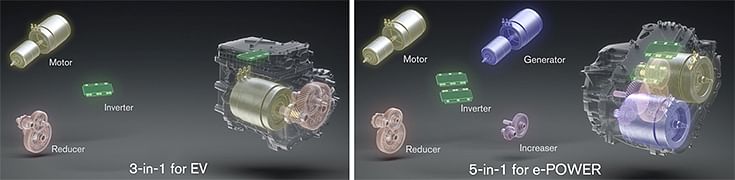

The X-in-1 moniker applies to both Nissan’s e-Power hybrid drivetrains (‘5-in-1’) and EVs (‘3-in-1’). Compared with the original Leaf, integrating the motor and inverter and using direct cooling of electronic components in the inverter has shrunk the package by 25% on current models.

Although e-Power wasn’t launched until 2016, a Leaf-based prototype first ran as early as 2010. Since then, the drivetrains have been steadily improved.

Nissan's ‘X-in-1’ powertrain packages will reduce driveline costs by 30% by 2026

Nissan's ‘X-in-1’ powertrain packages will reduce driveline costs by 30% by 2026

With 3-in-1, the EV motor, inverter and reduction gearbox are combined into one module, making the three components a further 10% more compact. It’s a similar story with the 5-in-1 drives. The latest versions have shrunk by 20% thanks to the same integration but by adding the series-hybrid generator and ‘increaser’ (combustion engine) into the same module, it shaves off a further 10%.

Cost reductions also come from parts sharing across the range of motors, which now use less than 1% of rare-earth elements in the magnets. Engineers achieved this by modifying the shape of the motor’s rotor surface to reduce heat loss.

Previously, it had suppressed the generation of heat by separating the magnets arranged around the rotor. With the modified design, they have been able to integrate magnets closely and this in turn has allowed the reduction in rare-earth materials.

Reducing size involves increasing bangs for buck generally or, in tech speak, improving power density. That includes the inverter, which, apart from merely swapping DC for AC and back again to make DC batteries compatible with AC motors, performs all the control electronics of the drivetrain.

For example, the semi-conductors in the second-generation e-Power inverter are 40% smaller than in the first generation and internal wiring harnesses have been ditched in favour of joining bits and pieces like circuit boards directly together. With X-in-1, the power density will increase even more with the introduction of silicon-carbide chips.

RELATED ARTICLES

Inside Three-Pointed Star's Global EV Rethink and Why the CLA Matters More Than It Seems

After years of building EVs under a separate identity, Mercedes-Benz is folding electric models back into its core brand...

Why India’s CBG Revolution is Stuck in Neutral

Seven years after a bold promise to build 5,000 plants, India’s compressed biogas sector is struggling to move past the ...

The Car that Exists Before it Exists

The car you buy today was likely built twice — once in software, once in steel. The companies that have figured out how ...

01 May 2023

01 May 2023

6466 Views

6466 Views

Ketan Thakkar

Ketan Thakkar

Arunima Pal

Arunima Pal

Anurag Chaturvedi

Anurag Chaturvedi