Tech Talk: How sodium-ion batteries could slash the price of EVs

The replacement for lithium-ion batteries is more sustainable, provides greater energy density, and is much cheaper too.

The accelerating march of progress must be giving product planners at car manufacturers a tough time.

Car technology has never been in such a state of flux as it is now, and given lithium-ion batteries only really became a commercial big deal in the 1990s, the sudden shift towards cars powered by them is extraordinary.

But historical perspective as to what comes next is always useful. A close look at the single-cylinder engine of the Benz Patent-Motorwagen of 1885, for instance, reveals a crankshaft and internals exposed to the elements, something that’s unthinkable today.

Given how fast things change in this business, chances are lithium-ion batteries – which have drawbacks in terms of sustainability, energy security and cost – will be overtaken by another type of energy storage. Sodium ion batteries (SIBs, also known as Na ion batteries or NIBs) have been on the horizon for a while but they weren’t expected to be mature enough for cars for some time yet.

But early in January, Chinese car manufacturer JAC announced it was shipping a small electric car from its Yiwei brand equipped with a SIB from Hina Battery. JMEV, another Chinese firm, also announced the rollout of a new EV powered by SIBs from Farasis Energy. The JMEV EV3 (Youth Edition) is a micro-EV city car and has a range of 156 miles / 260 kilometres.

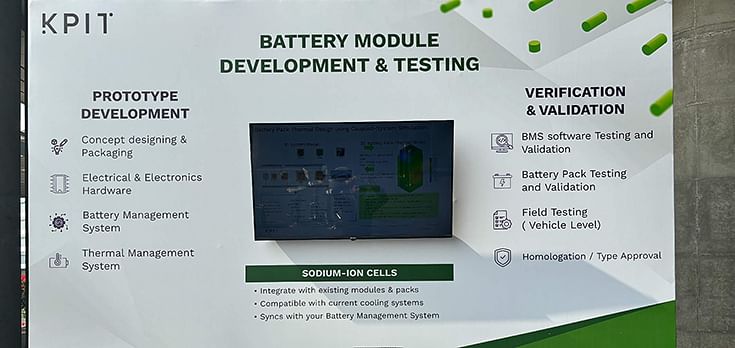

India's KPIT Technologies has unveiled its Sodium (Na)-ion battery tech which offers extended lifespan with 80% capacity retention for 3,000 – 6,000 cycles, energy density ranging from 100-170 Wh/Kg and faster charging.

India's KPIT Technologies has unveiled its Sodium (Na)-ion battery tech which offers extended lifespan with 80% capacity retention for 3,000 – 6,000 cycles, energy density ranging from 100-170 Wh/Kg and faster charging.

The downside of SIBs is mainly the lack of energy density, which goes hand in hand with increased weight (too few Wh/kg compared with lithium technologies), but the upsides are substantial.

SIBs are benign, containing no lithium or cobalt, and sodium is abundant worldwide. The electrolyte is simpler and the current collectors of the electrodes can be aluminium instead of copper, which is more sustainable and cheaper.

Overall, SIBs are around 30% cheaper than lithium ion. Given that the battery of an EV today is roughly 40% of the cost of the entire car, that’s a major benefit.

Manufacturers are working on increasing the energy density of SIBs and the JMEV EV3 battery is quoted as storing 140-160Wh/kg but Farasis is aiming for a second generation with an increased capacity of 160-180Wh/kg this year.

Turn that around another way and low energy density means that to give the range of a powerful lithium-ion battery, a SIB would have to be heavier, which in turn would affect range.

Farasis has set itself a target of 180-200Wh/kg by 2026, making the SIB suitable for a wider range of applications. It is still low compared with a typical lithium-ion EV battery, which can be around 270Wh/kg. That said, serious commercial development of SIBs took a back seat as lithium-ion technology came to the fore in the 1990s so there’s some catching up to do.

SIBs work well in cold weather, are safe and cost less than lithium ion so they have a variety of non-automotive uses too. Chinese giant CATL is also developing them, as is Sweden’s Northvolt and Sheffield-based Faradion.

ALSO READ: KPIT unveils breakthrough Sodium-ion battery technology to alleviate Lithium dependency

Stellantis invests in Tiamat and affordable sodium-ion battery technology

RELATED ARTICLES

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

How the India-EU Trade Deal Could Quietly Reshape the Auto Industry

While immediate price relief for the buyer is unlikely, the India-EU FTA will help reshape long-term industry strategy, ...

Policy, Protectionism and Pressure: Inside India’s Construction Equipment Downturn

India’s construction equipment sector faces a tough battle as it takes on cheaper imports from China and a slowdown in g...

26 Mar 2024

26 Mar 2024

16939 Views

16939 Views

Shahkar Abidi

Shahkar Abidi

Prerna Lidhoo

Prerna Lidhoo