SIAT 2017: future tech factory enthralls

With 1,400 delegates from 21 countries and 180 exhibitors with products and tech covering BS VI, vehicle crash and safety, e-mobility, telematics, NVH, simulation and modelling, SIAT 2017 was automotive R&D at its best.

Aligned with ongoing trends and new advancements, the Symposium on International Automotive Technology (SIAT) 2017, organised by ARAI in association with SAE India, NATRiP and SAE International, was all about smart, safe and sustainable mobility.

The biennial event, organised from January 18-21 at ARAI’s campus in Kothrud, Pune, hosted 178 exhibition booths showcasing new products and latest technologies by automotive R&D providers and component makers. Of these, 104 stalls represented foreign companies while 74 were Indian.

The exhibits were focussed on areas covering BS VI emission norms, vehicle crash tests and safety, advanced driver assist systems (ADAS), telematics, hybrid and electric mobility, noise-vibration-harshness (NVH), simulation and validation tools.

The four-day event was inaugurated by Sanjay Mitra, secretary, Ministry of Road Transport and Highways (MoRTH) and Shipping. The opening session saw the presence of RK Malhotra, president, SAE India; Sanjay Bandopadhyay, CEO, NATRiP; T Mookiah, associate director (R&D), Vikram Sarabhai Space Centre (VSSC); and Murli Iyer, executive advisor – Global, SAE International.

“The government of India is investing in automotive R&D on priority. It has earmarked Rs 4,000 crore worth of funding for NATRiP, which includes the expansion of capabilities across ARAI (Chakan, Pune), VRDE Ahmednagar, GARC Chennai, iCAT Manesar and at other sites. The R&D is focussing in the areas of powertrain development, passive safety, CAD / CAE, and homologation. Sixty percent of these facilities are complete,” said Bandopadhyay, while giving updates in his address.

Elaborating on other key developments, he added, “The passive safety lab at iCAT Manesar has opened last year and has also started crash tests. GARC Chennai is also operational now. We have recently installed one-of-its-kind copper extrusion machine at GARC, which is working on the front of vehicle scrapping process. The government of India has requested private companies under the public-private partnership (PPP) model to join hands in setting up and operating these upcoming state-of-the-art facilities. We have also invited RFQs in this regard. We want to leverage funds available with us. Our upcoming facilities can also work as incubation centres for start-ups. We are also paying attention to skill development projects.”

Giving the government’s perspective on the auto industry, Sanjay Mitra of MoRTH, who was also the chief guest, said: “Whenever we have felt the need to discuss the critical issues facing the automotive industry, we have called upon ARAI. The rate of accidents and fatalities are a grave cause of concern for India’s overall public health. Last year’s statistics say that more than 150,000 citizens succumbed to road accidents and many more saw serious injuries. To address these issues, some fundamental steps have been taken in the Motor Vehicles Act 1988, and the amendments are with the standing committee in the Parliament. We are going to set up inspection and certification centres in India to ensure that safer and cleaner vehicles ply on the roads. We have also commissioned studies for scientific and ambient air quality measurements. SIAT 2017’s focus on safety, alternate fuels, electric vehicles and emissions are all aligned with that of the government of India’s.”

Shortly after the first session concluded, a two-wheeler prototype (scooter) developed using the lithium ion battery of ISRO was unveiled by Sanjay Mitra. Sanjay Bandopadhyaya, CEO, NATRiP; Rajan Wadhera, president, ARAI; Vikram Kirloskar, VP, ARAI; Rashmi Urdhwareshe, director, ARAI; Murali Iyer, executive advisor, SAE International; RK Malhotra, president, SAE India and T Mookiah, associate director, R&D, Vikram Sarabhai Space Centre, were also present on the occasion.

The lithium-ion battery, indigenously developed by Indian Space Research Organisation (ISRO) for space applications, has successfully been put to use in an electric two-wheeler by ARAI. It can be recalled that Autocar Professional was the first media to break news about ARAI teaming up with ISRO for jointly developing the lithium ion battery technology for automotive applications early last year.

The lithium ion-powered prototype scooter marks a noteworthy step in the direction of attaining self-sufficiency in indigenous manufacture of these batteries in India. ARAI officials say that this landmark development could provide a substantial boost to India’s current status of electric mobility.

While sharing some details of the prototype (two-wheeler) Anand Deshpande, convenor of SIAT 2017, said: “This is a landmark development under the joint research project of ISRO and ARAI, where the lithium ion battery technology developed for space applications was successfully adapted for the automotive segment. We at ARAI have worked upon on various factors like battery management system, lab testing, road testing, and automotive duty cycle at different temperatures, charge and discharge.”

“In space applications, reliability is of paramount importance. However, in the automotive segment affordability is equally important. Thus, our teams are now working in this direction. The prototype is loaded with 48 volt, 50 ampere-hour battery and successfully runs up to 90km once charged for two hours. We are working on reducing the charging time and have set the target to bring it down to one hour initially. It does not use much electricity for charging and the running cost per kilometre could be as less as 20-30 paise per kilometre. The vehicle can attain the speed of 40-50 kilometres per hour”, he added.

SMART MOBILITY

Lauding ARAI’s contribution not just to the Indian automobile industry but globally in terms of providing resources to the industry, Dr Pawan Goenka, MD, Mahindra & Mahindra, participating in the first plenary session on ‘Smart Mobility’, said: “The auto industry is at the verge of disruptions which are unfolding, which are very real this time and coming from the need for environment protection, energy conservation, safety and trigger of technological advances that are happening in telematics, electronics, computing, sensor and I&T. The possibilities that we are exploring now are giving rise to smart mobility, be it emission control, connected cars moving to autonomous mobility or mobility internet enable rise in new business models.”

Elaborating on smart mobility, he said there are clearly four ‘Cs’ which are defining smart mobility – clean and safe, connected, cost effective and convenient.

“Electric cars have reached a point from where they could take off anytime soon and among zero emission technologies are the highest probability to become mainstream. India could take the lead in EVs where we are behind today but I do think we can take a lead if the government of India, OEMs, suppliers and consumers come together. Importantly, India must focus on having its own technologies and product IPR for EVs and not simply become importers of technology and components. To achieve this, all stakeholders need to work together,” he said.

Speaking on the increasing energy needs of the country, hydrocarbon imports and CO2 management and local environmental issues and the role the transport sector, Dr Ajay Mathur, director general, The Energy and Resources Institutes (TERI), said India clearly needs to work on advance fuel efficiency standards.

Stressing the need of alternate fuels and bio fuels which provide the largest amount of savings that are possible, this area has not been explored to the extent it needs to be in India. “India has intended more for electric fuel but is not getting there and use of electricity in the transport sector in buses and public transport needs to increase due to the benefits it offers in energy use and congestion. Electrification of buses provides the best alternative in operating cost, air pollution, financial model or their sustainability,” said Dr Mathur.

Dr Mathur is confident that steps like moving freight from road to water, fuel efficiency, increasing public transport, alternative fuels and bio fuels will ensure large reduction in hydrocarbon used by the transport sector by 2030 will move towards more sustainable future.

The plenary session on a relevant topic like Smart Mobility also saw some pertinent questions asked by delegates on areas such as use of alternative fuels and technologies available.

Strong support for auto industry: Anant Geete

The biennial event, organised every alternate year since 1987, concluded on January 21. The valedictory function saw chief guest Anant Geete, minister for Heavy Industries & Public Enterprises, and guest of honour Mrs Eva Molnar, director, Sustainable Transport Division, (The United Nations Economic Commission for Europe) UNECE attend.

Also present were Vishvajit Sahay, joint secretary, Department of Heavy Industry, government of India; Rashmi Urdhwareshe, director, ARAI and Anand Deshpande, deputy director, ARAI and convenor of SIAT 2017.

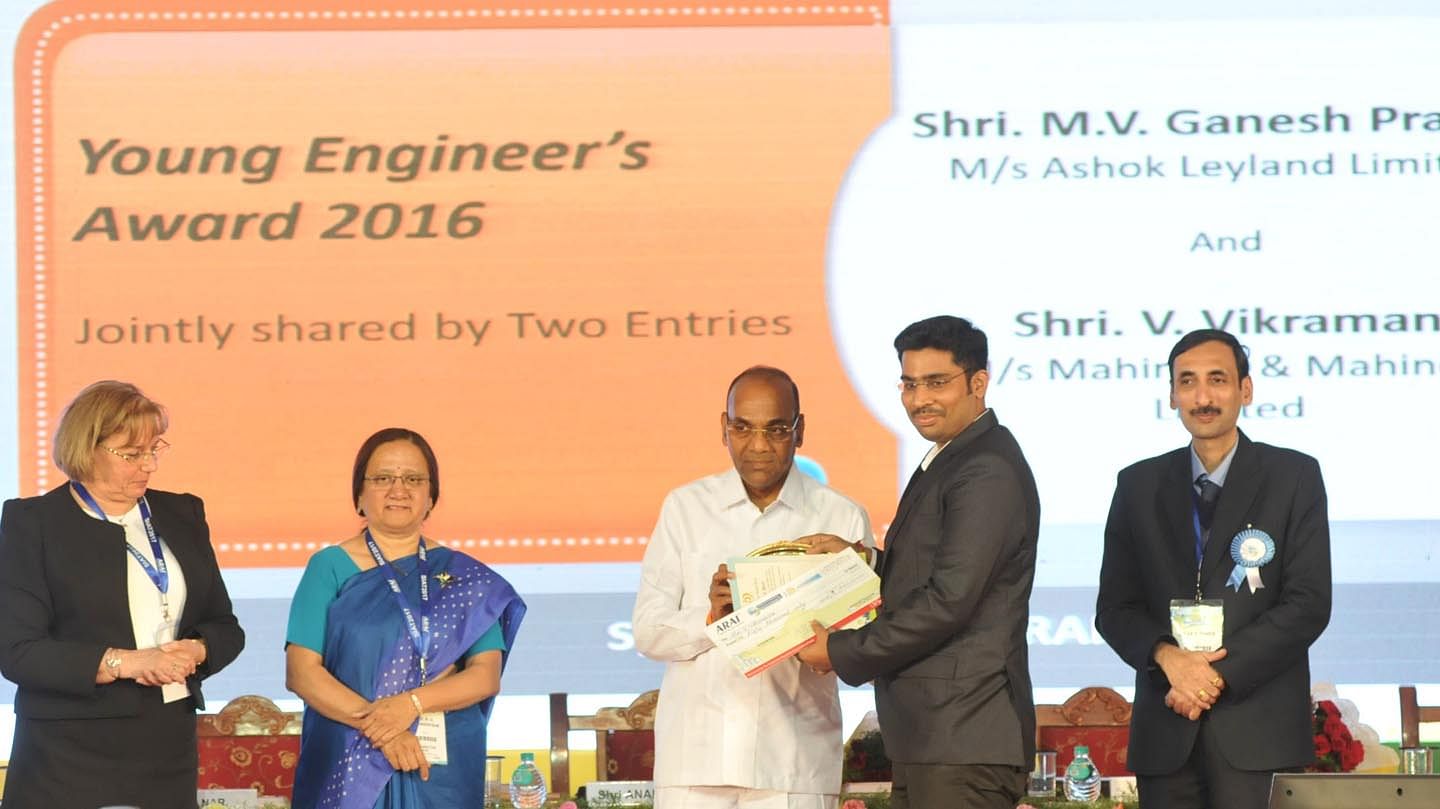

(L-R) Eva Molnar, Rashmi Urdhwareshe, Anant Geete, ARAI Young Engineers Award winner V Vikraman and Anand Deshpande during the valedictory function of SIAT 2017 at the ARAI Campus.

Anant Geete said, “The way technology is moving ahead, we are hoping that there will be driverless cars on the roads of India in the coming days. Today, our country stands as the biggest market for automobile manufacturers and investors. Cities like Pune and states like Tamil Nadu and Haryana are offering big scope and opportunities to investors and car manufacturers. This is the time when we need to showcase our strong presence globally.”

“All the ministries are coming together to make a decision of reaching from BS IV to BS VI by 2020. The automobile sector has always contributed to our GDP, economy and employment. Hence, we need to give strong support to this growing sector,” added Geete.

Addressing the media during the valedictory function, Eva Molnar said, “The change in the mobility is fast and very much visible in India and with this the country is expecting to develop 50 centres for technical inspection in near future.”

Commemorating ARAI’s golden jubilee celebration a ‘Golden Jubilee’ souvenir and bibliography was unveiled by the dignitaries present during the concluding session of SIAT 2017. Subsequently, ARAI also announced the first biennial ‘ARAI Young Engineers Award’ and its winners, MV Ganesh Prasad and V Vikraman. The award was in the form of memento and citation along with which the winners also received Rs 50,000 each from Anant Geete. SIAT 2017 marked the end of ARAI’s year-long golden jubilee celebrations.

Here's looking at some of the exhibitors at SIAT 2017.

HYBRIDTRONICS

One of the interesting exhibitors was a start-up trying to introduce an alternate fuel source of energy for commercial vehicles. Hybridtronics Ltd has developed a hybrid electric kit which enables a substantial increase in fuel economy and reduced emissions too. The genesis of the start-up is in the USA when the founder was sponsoring a research programme and decided to look at commercial application of this technology in India.

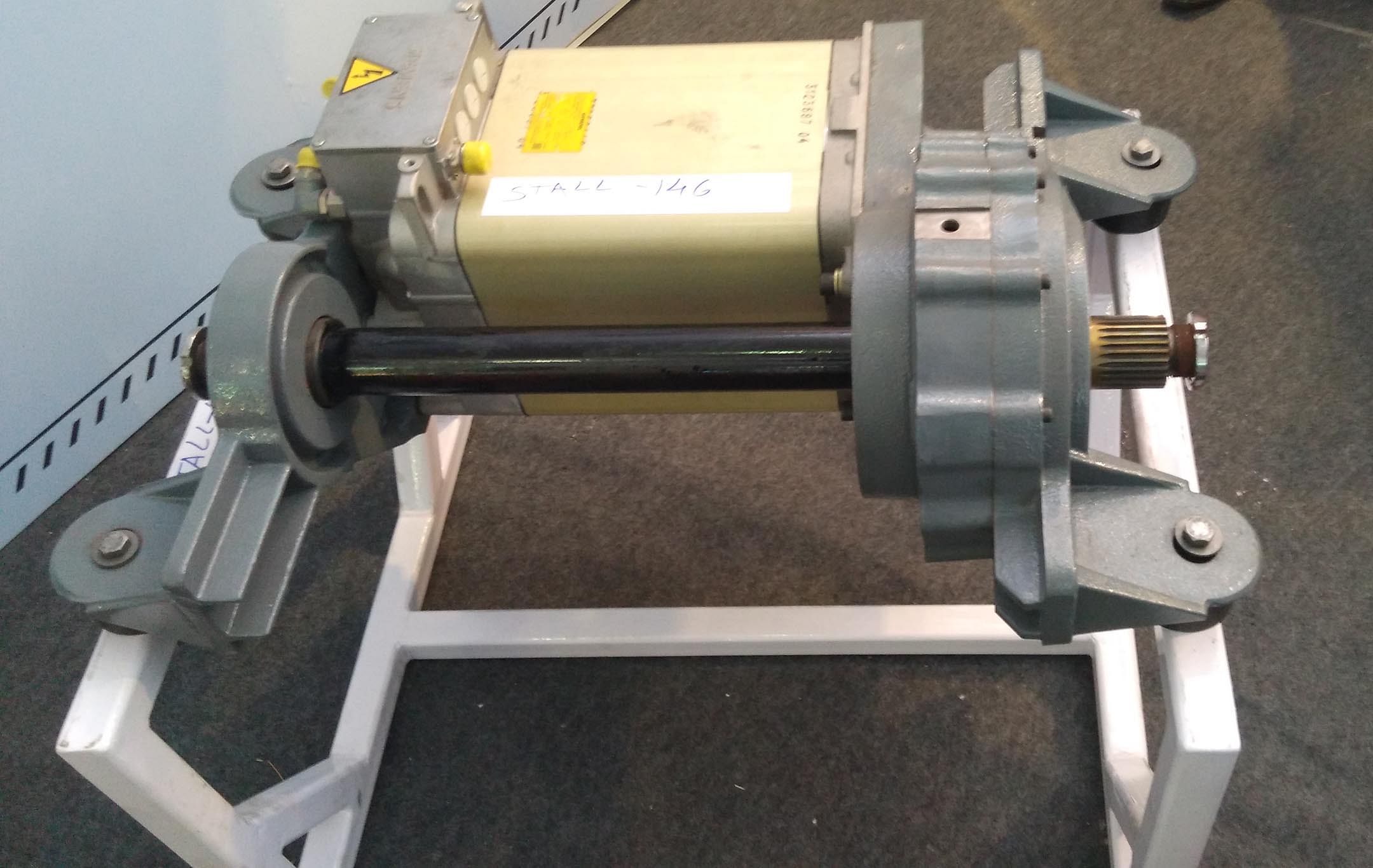

Hybridtronics' hybrid electric kit enables a substantial increase in fuel economy and considerably reduced emissions too.

The hybrid electric system/kit is designed to be retro-fitted onto existing vehicles. The hybrid kit consists of a traction motor, traction drives, a battery pack, a torque coupler and sensors in the accelerator and pedal which are flexible in their placement. The electric motor is connected to the propeller shaft around the middle of the vehicle, after the transmission. In the initial lot of vehicles, the company used a carbon belt coupling. For added durability and robustness, it also incorporated a silent chain drive. This entire setup lies between the chassis frame rails and is attached to the vehicle using a custom mounts made of steel. After an initial few years of research, the company has developed two prototypes on the Tata 1512 platform three years ago and is now set to commercialise this technology.

Explaining the technology and the benefits in fuel efficiency and to the environment, Anshu Dewan, director, Hybridtronics, says, “This hybrid-electric application is similar technology typically applied in hybrid vehicles like the Toyota Prius and a frugal version of it towards CVs and any vehicle which has a lot of braking is where this technology becomes highly effective like a city bus.”

The company is working with ARAI and other agencies for component level testing which will followed by type approval on the 1512 platform. However, there are challenges in terms of infrastructure as some labs in India are not equipped to handle such large components. Testing a battery pack is not possible in India and overcome such challenges the company is looking at certification from abroad.

“We are working on creating an economically viable hybrid electric kit because there are many good technologies are available but they are not economically viable without subsidy so we are trying to make them viable even without subsidy,” says Dewan.

A bus, which typically covers 30-350km a day with this hybrid electric kit, will improve its fuel economy by 20 percent, the kit paying back in three-and-a-half years. Over 10 years, the savings would be enough to buy a new bus chassis.

When asked about end customer usage, Dewan said, “We are open to OEMs and the aftermarket, but the best value can be captured in the aftermarket where we offer retrofit solutions. One of the benefits we have over an OE-fitted hybrid is that those systems are not possible to remove whereas our system can be removed and installed in new vehicles.”

Given that in India 70 percent power is in thermal form and there’s considerable pressure on the existing grid, hybrid electric vehicles are going to be better value for money with improved technology. The company is working on its next projects to fit this kit on the Traveller platform, Mahindra Bolero and smaller GVW CVs including pick-ups, buses and trucks.

HORIBA INDIA

Global engine and vehicle testing equipment provider, Horiba India showcased four key products including a portable measurement system, mobile altitude simulation and vehicle automation system and motor exhaust analyser largely targeted at the upcoming BS VI norms in India. “We want to be a complete solutions provider for our Indian customers, right from bench testing to field testing that is a test lab to the real world,” said a company official.

The company, which has been in India for almost a decade, has invested Rs 100 crore in a new India technical centre in Pune. The Horiba India Technical Center comprises test facilities equipped with automotive test systems, and a showroom of scientific instruments where clients can view product demonstrations.

Horiba India’s 300-strong team includes 80 engineers dedicated to work on the automotive sector, which contributes nearly 30-40 percent of its total business in India.

DASSAULT SYSTEMES

This 3D experience company which offers leading solutions to transform the way products are designed, produced and supported is engaged in various areas with the auto industry including vehicle program intelligence, virtual garage industry solutions, global validations, proven performance, smart, safe and connected industry solutions, target zero defect solutions and lean production run.

The growing electronics content in vehicles offers a big opportunity for it to offer precise solutions to OEMs and Tier 1 suppliers. With its new 3D platform which has innovative solutions for product design, development, simulation and manufacturing, Dassault Systemes offers complete development aspects such as managing data, lifecycle, and process in one single platform.

The company has been working with Tier 1 and OEMs to help make vehicle lightweight, using high- strength materials and reducing product development cycle. According to company officials, “There is pressure on cost and development cycle time and therefore companies need to take a scientific approach to bring products to the market. Dassault Systemes works on a user and market-centric approach.”

The company’s new 3D platform can be accessed by multiple engineers and cross-disciplines of teams which help in seamless integration, data connectivity and sharing of inputs. Collaboration at multiple locations, either for re-designs or co-designs within teams, helps cut down the development cycle time and also reduce cost.

ROTARY ELECTRONICS

Bangalore-based Rotary Electronics, which makes products such as sensors, switches, relays and solenoid, ECUs and mechanical components, displayed its new product range and some of its standard products.

Over the past year, the company has consolidated its sensor business categorising them and focused on key segments. It has developed a wide range of sensors for customers to pick and choose without passing on the development cost to them. It has developed a complete range making it as a standard product with in-house validation and testing.

Speaking to Autocar Professional, S Purushothaman, director, Rotary Electronics, said, “We have taken out all the requirements from different customers especially in the filter area, studied the products in the market, and are getting in touch with every filter manufacture to understand their needs and come up with standard solutions.”

Another new development which the company has patented is an integrated auto drain system with in-built ECU, sensors and actuators unit. This makes it a single unit unlike the earlier one where all these were independent units. OEMs will likely be interested in this product for in view of the upcoming BS IV (for CVs) and BS VI emission norms. The auto drain system for the diesel filter helps reduce emission because of the water contamination in the filtration system. It will also reduce the high damages that can happen to the FIB or the engine.

“In BS IV and BS VI, the FIB and engines are going to be very expensive; this system will prevent those unintentional damages. It cleans the water automatically without driver intervention and reduces the fatigue on the drivers,” elaborates Purushothaman.

Rotary Electronics offers complete filter solutions starting from filter bowl, covers, automatic drain system, temperature sensor, fuel heater, mounting brackets, and mechanical components. The company has developed a range of magnetic speed sensors for off-highway applications where the challenge is high temperature and heavy vibration levels. Vacuum switches and pressure switches, which were not part of its portfolio, have now been developed indigenously. The company currently exports nearly 40 percent of its products and expects to post further growth on the back of its quality electronics products.

Purushothaman says, “We have diversified into various segments so the growth has been well balanced; auto contributes 60 percent of our business followed by the defence sector. We are qualified to export to the US defence market.”

Given its experience over two decades, Rotary Electronics is looking to capitalise on its strengths and expand its products range. Over the past 3-4 years, it has expanded in the sensor business fully on its own in-house capabilities. It is now working on a number of new programs and is also partnering some premier research institutes to develop new technologies for the auto sector.

AVL DISPLAYS PEMS FOR REAL DRIVING EMISSIONS

Market leader in powertrain engineering and development, AVL India showcased its portable emission measurement system (PEMS) for CO / CO2 and NO / NO2 emissions for real (time) driving emissions (RDE) testing. The upcoming real driving emission legislation for passenger cars in Europe calls for carmakers to carry out tests on road with PEMS to prove compliance with the newly defined RDE regulations. PEMS testing on cars requires small, lightweight devices that are compact enough to fit into the smallest of vehicles. According to officials at AVL, installing PEMS even in small cars is quick and easy.

The AVL officials also demonstrated their exhaust flow measuring device for application with passenger cars, heavy duty trucks and off-road mobile machinery. It is understood that the exhaust flow is required for the calculation of the exhaust mass emissions from the measured exhaust gas concentrations. The direct exhaust flow measurement with exhaust flow meters (EFMs) is a mandatory requirement for the EU real driving emissions.

The company says the AVL M.O.V.E EFM is based on the proven and robust differential pressure measurement principle. “It consists of the EFM tube installed on the tailpipe of the vehicle and the EFM control box, which includes the electronics and the pressure transducers. The EFM box is temperature conditioned to achieve the highest accuracy at changing ambient conditions,” reads an AVL document that highlights the features of the exhaust flow meter.

AVL also displayed its micro soot sensor (MSS) under its emission measurement instruments division. Sharper public attention on soot emissions and the associated continuous lowering of emission limits has resulted in increased development efforts on the front of exhaust after-treatment and combustion system development.

Explaining the requirement of MSS in the emission testing procedures, a company document states, “Currently, engine-type certification is limited to exhaust gas opacity, particle matter and particle number emissions. However, in engine development soot emission has always been measured as the first parameter because it is an important indicator of combustion quality and a main contributor to particulate emissions.”

AVL says the MSS is the only measurement system in the market that can determine the concentration of soot directly out of the primary measurement value, without cross sensitivity to other exhaust components like hydrocarbons, sulphates or NO2. Understanding that several OEMs are working on a cost-effective combination of (selective catalytic reduction) SCR and (exhaust gas recirculation) EGR systems for existing diesel engine platforms to meet the upcoming BSVI emission norms by 2020, AVL also showcased its PLUrea system.

This is a system solution for dynamic urea consumption measurement in SCR system development and application for diesel engines. It delivers online AdBlue (urea) consumption data for system monitoring on engine and chassis test beds, calibration of SCR-map, injector and system testing in lab and test bench environment and in transient test cycles.

AVL also demonstrated select aspects of electrification testing solutions at SIAT 2017.

RELATED ARTICLES

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

How the India-EU Trade Deal Could Quietly Reshape the Auto Industry

While immediate price relief for the buyer is unlikely, the India-EU FTA will help reshape long-term industry strategy, ...

Policy, Protectionism and Pressure: Inside India’s Construction Equipment Downturn

India’s construction equipment sector faces a tough battle as it takes on cheaper imports from China and a slowdown in g...

13 Feb 2017

13 Feb 2017

19389 Views

19389 Views

Shahkar Abidi

Shahkar Abidi

Prerna Lidhoo

Prerna Lidhoo