Sansera Engineering has Rs 300 crore business in the bag

Booming exports and a thriving domestic connecting rods business see Bangalore-based supplier target a Rs 1,500 crore turnover within three years.

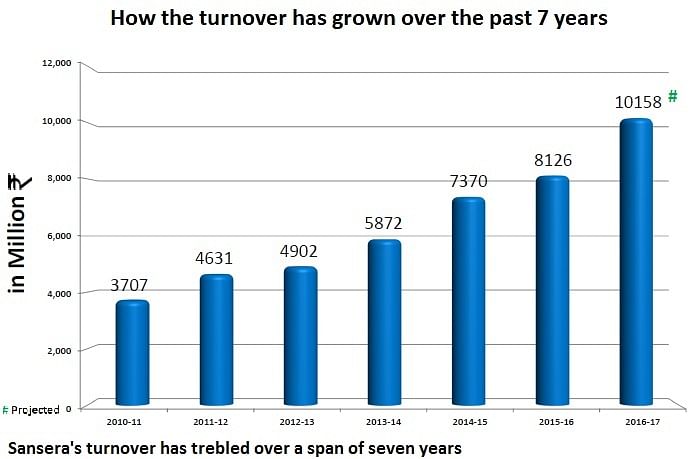

As they say, the tough get going when the going gets tough. The last two years of slow growth were a period of trepidation for the Indian automotive industry, particularly component suppliers. Bangalore-based Sansera Engineering Pvt Ltd though bucked the trend and grew at a rapid pace.

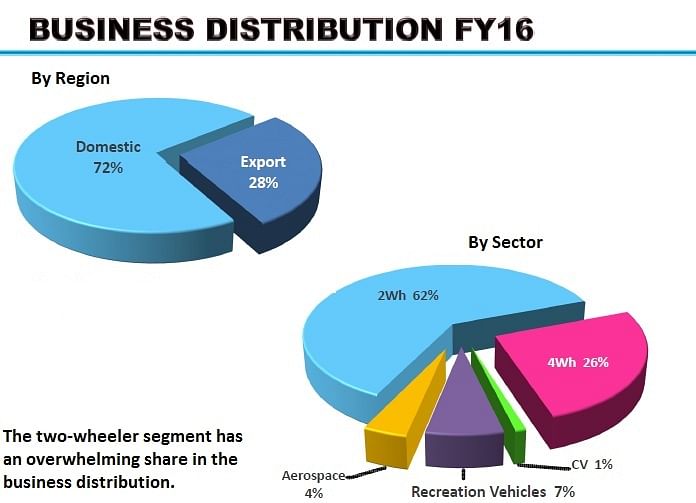

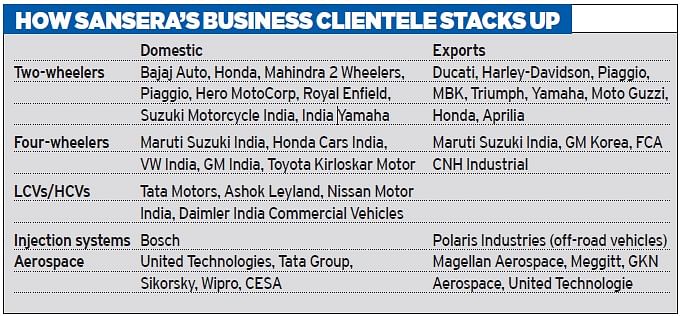

Thanks to buoyant overseas shipments to Europe and some Asian markets, exports accelerated, rising from 8 percent to 30 percent in the past four years. The same timespan also witnessed a commensurate spiralling in turnover from Rs 500 crore to Rs 890 crore in FY2016. Of this, Rs 820 crore accrued from the automotive vertical with exports comprising Rs 250 crore. The balance came from the forgings unit with the company’s aerospace division contributing another Rs 32 crore.

These numbers mean Sansera is in a comfortable position, having already bagged Rs 300 crore worth of orders for supply over the next three years where the focus will be on pumping up its passenger car business further while also strengthening its commercial vehicle portfolio.

Expected future growth will entail an expansion of the company’s manufacturing footprint as most of its manufacturing plants in Bangalore have reached optimum capacity utilisation and are being reorganised in preparation for future growth.

Hence, construction on a fifth manufacturing facility for machining in Bangalore at Bidadi is set to start from next month. Spread across a 15-acre plot, the first phase – involving an investment of Rs 35 crore – will see construction on a 150,000 square metre area, and will be Sansera’s largest facility in a single building. In phase II, the infrastructure and capacity will be doubled.

The new plant, which will make connecting rods for four-wheelers and LCVs, will also handle any new products or new orders. The Bidadi plant will help grow the overall business from Rs 1,000 crore in FY2017 to Rs 1,500 crore over the next 3-4 years.

The additional revenue will be mopped up from different vehicle segments – two-wheelers, four-wheelers and CVs –accruing from both exports and the domestic market.

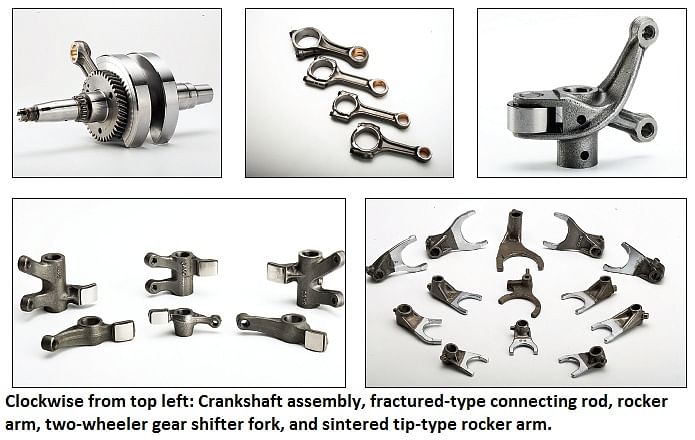

Incidentally, Sansera’s connecting rods business has been its key growth driver in terms of topline and profitability with the transition in focus from two-wheelers to the four-wheeler or passenger car segment over the last eight years reaping rich dividends.

Single-piece crankshaft for two-wheelers

The company also expanded its presence in the light commercial vehicle segment and has bagged new orders for supply of connecting rods to OEMs, predominantly in export markets. The component major is now entering into a new product line – a single-piece crankshaft for two-wheelers – which will cater to high-end and larger premium motorcycles as the market for these bikes opens up in India.

“We currently make assembled crankshafts for some of the major two-wheeler manufacturers like Bajaj Auto that involves assembling the two halves of the crankshaft with bearings, con rods and pins. These form the heart of the engine and together constitute a major chunk of the engine,” FR Singhvi, joint managing director, told Autocar Professional on a visit to Plant 7 in Bangalore. “We manufacture critical engine parts, most of which are still done in-house by OEMs or have very few players making these parts in the world. Continuing this tradition, we are getting into single-piece crankshafts and it should see adequate growth in the next 5-8 years.”

A Rs 20 crore expansion project at an existing facility in Bangalore is underway to make the single-piece crankshaft in volumes of 50,000 pieces per year. In the current year, a capex of Rs 150 crore will go towards various forging and machining capacities required in the second half of the year. In 2015-16, Rs 125 crore was invested. On an annual basis, Sansera is investing Rs 100 crore towards new business and incremental growth of business.

Sansera foresees much potential in the new product. Even heavy-duty vehicles powered by larger engines use single-piece crankshafts – ideally in a single-pin crankshaft, the crankshaft is in one piece with a connecting rod that is split and attached to the crankpin and will begin making it next year. Simultaneously, it is leaving the door ajar for a smooth transition of the product to the passenger car segment as well when the demand arises.

The company has developed its con rod business for four-wheelers over the past eight years. At present, it has a 6.5 million units per annum con rod capacity for four-wheelers and is expanding this to 15 million within three years to meet fresh demand.

The company also undertakes crankshaft machining for two-wheelers which it claims is done by very few players globally. Most OEMs buy crankshaft forgings and do machining in-house and the same is the case with con rods. Incidentally, Sansera has been approved by a car manufacturer to machine con rods for them outside of their facility.

Tracing the company’s roots

A Tamilian, S SekharVasan, chairman and managing director of Sansera Engineering, who started the company, was employed with TELCO in the mid-1970s in Chennai after completing his engineering from IIT Madras in metallurgy. The idea of starting his own auto components firm germinated then. After a few years, Vasan pursued his MBA course and thereafter Sansera was set up in Bangalore in 1987.

Focus on localisation

At the time, products were built to print as per OEM design specifications for which some machinery was bought and adapted to manufacture the required parts. However, not satisfied with the outcome and in the absence of adequate funds to buy special machines, the fledgling Sansera decided to design and manufacture machines on its own. Till date, the company has pioneered 500 machines that produce auto components with some being imported.

Two years after inception, three chartered accountant friends joined Sansera as partners. Today the CMD and JMD serve as full-time employees and are partners in the company. “We made a lot of mistakes but made improvements and kept learning. Today we have a highly developed system that we started in 1994-95,” says Vasan.

What helped was the availability of the necessary industry for machine building that existed in Bangalore at the time. “There was a time when imported controllers were very expensive. So we started making our own controllers. We were writing the software to do the cutting, writing algorithms, and overall doing a lot of things. Then the cost of the controllers started falling and duties reduced, so we started buying controllers and integrating them with our own machines,” reveals Vasan.

About four-and-a-half years ago, Sansera diversified into the aerospace sector, releasing one machine for the purpose only to realise that it was a lucrative business. Now Sansera is exploring further opportunities in medical implants of knee joints and hip joints as well as working with exotic materials for varied requirements.

For the past eight-odd years, Sansera has maintained a steady CAGR of 15-20 percent, which the CMD attributes to being at the right place at the right time in the backdrop of a growing auto industry. Also, the component major has pursued an aggressive localisation programme right from the start, indigenising key products like the rocker arm and gear shifter forks which were earlier imported. This added to the company’s growth trajectory and enabled it to stay ahead of the market curve.

With the worst now believed to be over in the Indian auto industry and India’s GDP on a new high, the management at Sansera is bullish of customer preferences shifting from two-wheelers to four-wheelers as disposable incomes rise and hence its expansion in this segment.

A walk around plant 7, located on the outskirts of the city at Jigani, reveals that it produces 6.5 million connecting rods annually. The current capacity can be ramped up to 10 million per annum here. The plant caters primarily to the four-wheeler business that is growing with large global vehicle OEMs and hence the need for upscaling. The company has forging, machining, heat treatment, metallurgy and engineering functions at Bangalore among others.

Every 15 seconds, one part rolls out with 135,000 parts being produced monthly here. The plant works on a three-shift basis and has 16 workers per shift per line.

Operations involve receiving the forging from the forging shop, grinding and rubbing operation, followed by drilling the hole. In the gantry operation, 10 machines are controlled by a single operator, with each machine undertaking a different function of bolt hole operations.

The part then goes for automated laser scribing and fracturing where the top half is split. Then it’s time for dressing of the fractured surface followed by torqueing and bush pressing, side milling, finished grinding to make the con rod fit and function properly on the engine, as well as weight reduction milling and finished boring and honing. Then the con rod part is sent to the automated inspection cell where the robot takes care of loading on the fixture. Thereafter, it is matched with the customer specifications in the drawings and the part number identified and put in the specific weight group.

New business

Singhvi admits that there are a number of new orders in the four-wheeler space as the two-wheeler business has already matured with Sansera having a presence with many of the major players. Hence, only incremental orders are in the pipeline in sync with the growth at the OEMs’ end.

For instance, Sansera commenced business with Fiat 7-8 years ago and now supplies to all its platforms globally. By 2018, it will be supplying 18-20 different con rods for 20 different Fiat engines as existing suppliers are being replaced or new platforms are necessitating addition to the supplier list worldwide. Other clientele includes Maruti Suzuki, Volkswagen and Toyota for connecting rods that are tailor-made for their engines. At present, passenger cars contribute close to 40 percent of its auto business, two-wheelers 45-50 percent with the balance 10 percent coming from aerospace and CVs.

The company has 10 plants of which the majority are located in Bangalore; one of them manufactures aerospace parts for Boeing and Airbus aircraft. There are also two forging units with other manufacturing facilities located at Manesar, Pantnagar and at Pune. Plans are to expand its manufacturing footprint in Gujarat in a year’s time – a 12-acre land parcel is being bought there over the next 3-4 months for a new plant at Vithalapur (where Honda recently expanded its scooter plant).

Sansera recently has bagged new business for supply of transmission parts starting last year for a carmaker and plans to approach other OEMs as well. However, it is still undecided about growing this new business stream since many rivals are already present in the fray.

The strategy for future growth will involve adding new customers and expanding the product portfolio with existing ones. While its customer list has grown from 21 to 30 in the past three years, Sansera has expanded its components range from 17 to 30.

In 2009, the company has posted a six percent growth, its lowest ever. Since then, it has been recording 5-20 percent year-on-year growth, thanks to having a healthy order book size consistently.

Officials maintain that it helps that they produce components that have a long gestation period with the customer working 2-3 years in advance. For instance, con rods which will be used in late 2017 have already been submitted as the engine will undergo rigorous testing in the interregnum.

Future trends

The future trends visualised in this field include weight reduction, change in material or design to deliver lighter engines that improve mileage and fuel efficiency.

Sansera is also working with OEMs on new designs and Singhvi says weight is being reduced by 5-10 percent while strength is being upped by alternating material. While common carbon steel was used in the products earlier, now micro alloy steel is employed due to its varied benefits of lower weight and better geometry. Of the total engine configuration, while the diameter of the con rod was earlier wide now it is getting squeezed which makes manufacturing a lot more challenging.

The other shift is from carburetted engines to fuel injection systems. Transition to port injection and direct injection systems is also being seen as newer technologies percolate.

Aerospace — The next frontier

After the auto parts business, this correspondent next visits the aerospace plant situated nearby. This unit makes high precision parts for lighting systems, cargo systems and seating systems that are supplied to the Tier I suppliers globally for fitment in the Airbus and Boeing aircraft among others.

Sansera claims it has no technology partnerships and all technologies are home-grown. The aerospace division has an engineering centre with 15-20 engineers that develop in-house products based on market demand.

Each plant has its individual engineering team while at the corporate level a larger engineering centre operates with about 70 engineers. The aerospace plant produces 20,000 parts per month and makes 400 different parts. Rakesh SB, associate vice-president, who heads this division, walks this correspondent around pointing out that these are safety parts and involve first article inspection and check. Only thereafter they move to the assembly line for manufacturing in larger numbers. Different kinds of assemblies are undertaken here like bush pressing, rivet pressing, electrical bonding with 43 different machines functional.

It is clear that Sansera has a lot going for it. It has escaped largely unscathed from the economic slowdown and, unlike many auto component companies, is not caught in the vortex of excess production capacities. It has been among the fortunate few that have taken the right decisions at the right time and have benefitted from it. The future seems equally bright as new vistas of opportunities beckon this fast growing company. If its order book size is any yardstick, Sansera is on a no-holds-barred growth trajectory.

RELATED ARTICLES

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

How the India-EU Trade Deal Could Quietly Reshape the Auto Industry

While immediate price relief for the buyer is unlikely, the India-EU FTA will help reshape long-term industry strategy, ...

Policy, Protectionism and Pressure: Inside India’s Construction Equipment Downturn

India’s construction equipment sector faces a tough battle as it takes on cheaper imports from China and a slowdown in g...

By Shobha Mathur

By Shobha Mathur

09 Aug 2016

09 Aug 2016

173769 Views

173769 Views

Shahkar Abidi

Shahkar Abidi