Indian carmakers step up capabilities to make safer cars

The government’s aggressive road safety drive, stringent and mandatory safety norms, and a far more safety conscious consumer are driving carmakers to make vehicles that are protective of their occupants and even pedestrians.

India is well known, rather, unfortunately, for its poor track record of road accidents, fatalities and injuries. While industry stakeholders, the government and policymakers are doing their bit to reduce the number of road crashes, the passenger vehicle industry has put its shoulder to the wheel of safety, looking to develop and produce safer made-in-India cars.

As India evolves towards becoming a mature auto market along with rising disposable incomes, affluent and well-travelled citizens and a population which majorly comprises digitally connected youth, the aspirations of the Indian car buyer are changing dramatically — he/she wants to enjoy motoring and wants to be safe while doing that.

It was not long ago that buyers in the entry-level to midsize car segment would prefer to empty their pockets on shiny alloy wheels and in-car entertainment systems rather than life-saving features like an airbag, which most OEMs offered as an option and at a price. Thus, a lack of consumer awareness amplified by the OEM thought process of just conforming to weak legislation which did not mandate occupant crash safety, meant that the majority of the mass-market vehicles lacked safety kit, at least in their ‘highest-selling’ variants. What’s worse is that basic body structures in many an entry-level model did not have any crash resistance altogether. There were exceptions like Honda, which tried sticking to its core values of safety by keeping airbags and ABS as standard across all trims of even volume-centric models such as the Jazz hatchback but couldn't survive the cut-throat competition in the Indian market where OEMs are gunning for profitability.

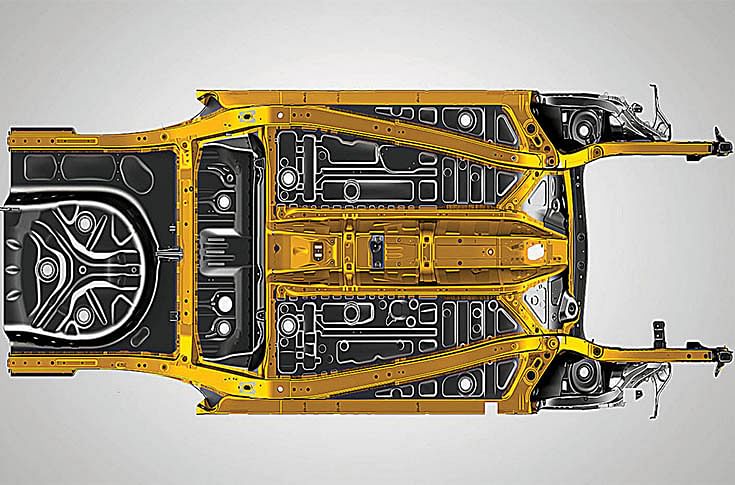

The Tata Nexon has an energy-absorbing body structure with high-strength steel construction and critical reinforcements.

Cut to present-day, PVs (and two-wheelers) are set to become safer what with a slew of mandatory safety measures set to kick in. What’s driving this is the change in mindset of the growing band of discerning consumers across the country, who are unwilling to spend on unsafe vehicle models. Importantly, they are now willing to spend more on safety equipment inside their cars.

Safer cars for India

What has helped increase consumer awareness about vehicle safety in recent years is the sustained effort from non-profit organisations such as Global NCAP through its 'Safer Cars for India’ programme. Launched in 2014, it started putting crash performance safety ratings on some of the largest selling models in India out in the public domain, sparking off a huge debate in media and across social media platforms. It was not long before the government took cognisance of the issue and brought in a slew of regulatory reforms, such as crashworthiness of cars.

Like the leapfrogging of emission norms to BS VI from April 2020, India now takes a massive leap in its vehicle safety regulations. It all began in a phase-wise manner for new models in October 2017 and will now encompass all PVs by October 2019. This would also see it overtake China and the USA as both don't mandate norms for pedestrian safety as yet.

Who was at fault all this while for India being in the slow lane of vehicle safety? While the jury continues to be out on that, some point to the government and many attribute OEMs' penchant for cutting costs. The latter is true to some extent, seen in ‘clever’ hoodwinking of regulations by some carmakers in favour of margins. For instance, offering the passenger-side ORVM (Outer Rear View Mirror) — a bare-basic driver necessity — as a trim upgrade feature was a practice for decades by the country's largest carmaker. Yes, the cars still meet basic homologation requirements, but they have also helped spread unsafe driving habits on dangerous Indian roads.

Successful companies keep track of consumer trends and PV makers had begun to realise the growing importance of the safety quotient in the consumer’s vehicle purchase decision. They started crash testing their cars to global standards, and subsequently improving on the results.

As David Ward, president and CEO of Global NCAP says, “The zero-star results and stark images of collapsed bodyshells were shocking but they also acted as a catalyst for increased consumer awareness and demand for safer vehicles. Whilst some manufacturers tried to disparage our tests, others acted more positively, making airbags standard and trying to improve their crash tests’ star ratings. This culminated, last December, in Tata Motors achieving the historic milestone of India’s first ever ‘five-star’ rating for its Nexon. And now three and four stars are much more common in our Safer Cars for India tests, quite a contrast to the status quo five years ago.”

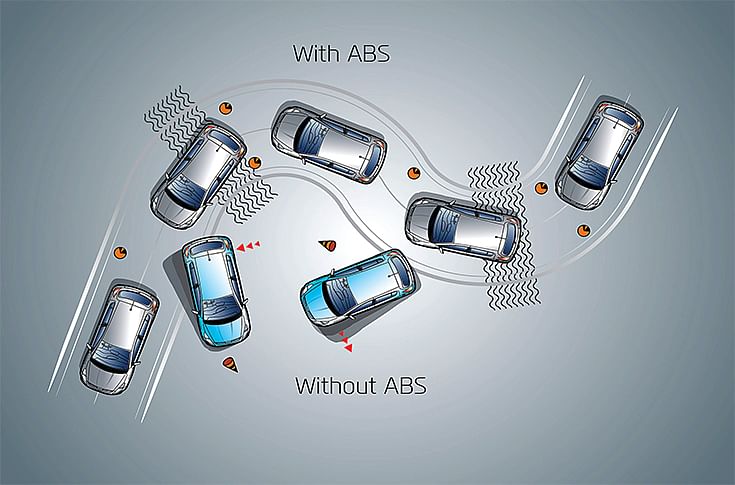

The anti-lock braking system (ABS) has become mandatory for all cars on sale in the Indian market this month onwards

Here’s tracking the progress of some key OEMs which have embarked on the road to safety.

Walking the safety talk

Tata Motors should be lauded for leading the safety drive, having aggressively worked at the engineering level and optimised its products to deliver high levels of safety in its new-generation cars. Not many may know that the carmaker was the first in India to invest in a crash test facility back in 1997, when there were no such benchmarks in India. Historically, this has allowed Tata Motors to not just meet the law of the land, but also achieve smart results including having one of the safest cars to be on sale in India — the Nexon, a totally indigenous product.

The compact SUV, Tata's first attempt at the segment, scored five stars for adult occupant protection (AOP) and three stars for child occupant protection (COP) in Global NCAP's results announced in December 2018. This improvement came after Tata Motors equipped the car with a seatbelt reminder (SBR) each for the driver and co-passenger as standard, after the Nexon had received a four-star rating earlier in the same year. Tested for both front-and- side-impact (meeting UN95 side-impact protection requirements), the Nexon's structural integrity and overall safety was evaluated with the combined analysis resulting in a full five- star rating — the highest AOP score of 16.06/17.00 amongst all models tested from the Indian market so far.

Rajendra Petkar (pictured above), CTO, Tata Motors, says: “The Nexon's body structure is engineered to effectively manage and absorb impact energy. From an engineering perspective, there are many innovations in the engine bay and in terms of cabin packaging. The load path and crash energy management through the structure involves novel section designs, geometries and combination of different material grades. While intelligent packaging and design of pedal blockers helped in controlling lower leg injuries, at the same time, occupant energy is efficiently dissipated through optimised restraints inside the vehicle's cabin which include dual airbags, seatbelts with load limiters and pre-tensioners, dashboard, seats, steering system and footrests.”

He adds, “Computational algorithms were also defined to enhance prediction accuracies, which, in the company's overall scheme of things, again helped in lessening the impact of the accident on the vehicle.”

Another Indian OEM which has proved its mettle recently at the Global NCAP test grounds is Mahindra & Mahindra. The UV specialist earned a respectable second position after Tata Motors, with its latest MPV offering — the Marazzo — securing a four-star rating. A lesser known fact is that the Indian UV specialist had already showcased its engineering capabilities back in 2012, with its indigenously designed XUV 500 crossover scoring an appreciable four-star rating in the ANCAP (Australasian New Car Assessment Programme) test procedures, and the model also becoming a runaway success in India.

M&M has consistently been augmenting its know-how and strengths, an effort which is seen in the Marazzo, which received an overall AOP score of 12.85/17.00 in the Global NCAP tests conducted last year. With safety equipment including dual front airbags, ABS, SBR for driver and ISOFIX anchorages as standard, the MPV obtained four stars in AOP and two stars for COP.

The model was found to offer good protection for adult head and neck, marginal protection for the driver chest and adequate protection for the passenger chest. The pedals, however, showed some risk for the lower legs due to their displacement.

So, what gave the Nexon an edge over the Marazzo? While both cars offered good neck and head protection for the two adult dummies sitting in the front seats and even adult passenger chest protection offered in the two cars was similar, it was the protection for the driver’s chest which saw the Nexon inch ahead of the Marazzo.

As per details revealed by the Global NCAP, there was more than a one-point difference between the scores obtained for each of the driver’s chest. This is usually explained by the timing of airbag deployment and collapse of the steering column, combined with seatbelt load limitation. The test procedures allow a safe chest compression of up to 50mm, but both cars scored less than 32mm, where less chest compression means lesser chest-related injuries and risks. Remember that the chest is one of the three critical body regions in the frontal crash test, while the other two are the neck and head.

Both the Nexon and Marazzo offered good knee protection, so no differences there but lower legs is where the difference comes again into relevance — the Nexon scored one point better than the Marazzo in the driver left tibia. Also, in the lower leg, right driver tibia protection in the Nexon is 1.2 points better than in the Marazzo.

Last but not the least, pedal displacement in the Nexon scored full points while Marazzo fell 1.1 points short. Higher pedal displacement brings higher risks to the lower legs and this is penalised in the test results. On top of that, the Nexon scored full points in seatbelt reminder while Marazzo only scored half because of offering the reminder just for the driver.

As regards child occupant protection, the three-year-old dummy in Nexon had good protection to head and limited to the chest but in the Marazzo the head excursion went above the limits, exposing the head and losing all the points there.

According to R Velusamy (pictured above), senior vice-president, product development – Automotive Division, Mahindra & Mahindra, “Mahindra being a safety conscious organisation, we have cognisance to the increasing needs of road safety. We have designed our product portfolio with utmost importance to the vehicle’s safety. In fact, safety has been one of the critical elements of our vehicle design process not only today but over the last 10 years, way ahead of safety regulations being mandated in India. It is governed by our internal safety policy and we have institutionalised our safety policy bringing a consistent approach to enhance vehicle safety across our portfolio. We manage safety through a holistic approach.”

Shifting focus to the mass-market player and India’s leading car maker which has seen customers’ faith and trust instilled in the brand, easily measurable from its over 50 percent market share, Maruti Suzuki India has been incorporating use of high-strength tensile steel since 2012 in a wide variety of products, which has not only helped the vehicles shed weight but also add more strength.

Citing an example of the company's new-generation products, C V Raman (pictured above), senior executive director, Engineering, Maruti Suzuki India, reveals that while the company like any other is looking at consolidating platforms, it is ensuring that irrespective of the platform, the engineering team takes into consideration “managing the energy dispersion in the event of a crash and the structure the way we build it. So, yes definitely, it is a strategy forward for Maruti Suzuki."

In Global NCAP's results announced in September 2018, Maruti’s top-selling UV, the Vitara Brezza with standard dual front-airbags, ABS, and ISOFIX anchorages, achieved four stars for adult occupant protection and two stars for child occupant protection. The AOP was good and robust whereas the COP rating was only two stars due to the forward-facing positioning of the 18- month-old dummy in the test though the 3-year-old dummy received good protection. The markings for the ISOFIX anchorages were also incorrect, according to Global NCAP testing protocols.

Maruti Ignis being tested for pedestrian safety at Rohtak facility

While on one hand Maruti Suzuki has the Brezza, the company is largely inconsistent with safety in its products as could be assessed from Global NCAP's tests of the made-in-India, third-generation Swift hatchback. The car, again a popular customer choice, comes equipped with dual front-airbags, and ISOFIX (i-size) anchorages as standard, but could only get a two-star rating in AOP and a similar two stars for COP as well.

Global NCAP says the Swift's two-star result for adult occupants is due to the high compression to the driver chest, unstable structure and poor protection for the feet explained by pedal displacement on the driver side. The COP of only two stars is explained by the forward-facing positioning of the 18-month-old dummy in the test offering low protection and also the low protection offered to the chest of the three-year-old dummy.

The company has shifted its cars to the lighter and stiffer ‘Suzuki Heartect’ platform and Maruti's latest fourth-generation Wagon R now comes built upon the Heartect-A platform which makes it substantially bigger than the previous model and sees the use of up to 40 percent high-tensile steel.

Suzuki's Heartect platform is lighter and stronger, designed to meet crash norms and also help achieve good fuel efficiency

Then there’s Toyota, the world's second-largest vehicle manufacturer by volumes. Its Indian arm Toyota Kirloskar Motor has been following in the footsteps of the brand philosophy on a global level, which aims to achieve a society with zero traffic fatalities.

While Toyota is synonymous with safety and durability in the eyes of car buyers, the company tried to slightly deviate and cut corners with its Etios twins — Etios sedan and Etios Liva hatchback — which couldn't resonate well with the private buyer when launched in 2010, owing to their perceptile shift from the legendary 'Toyota build quality’. However, the Japanese major could have only done little as its ambition was to dive into the sea of small cars akin to its competitor Suzuki, but couldn't find the trick to raise margins. Essentially, what looked like poorly built cars for emerging markets, the dust around Toyota's ethos finally settled when Global NCAP certified the made-in-India Etios and Liva, which both scored a four-star AOP rating in 2017.

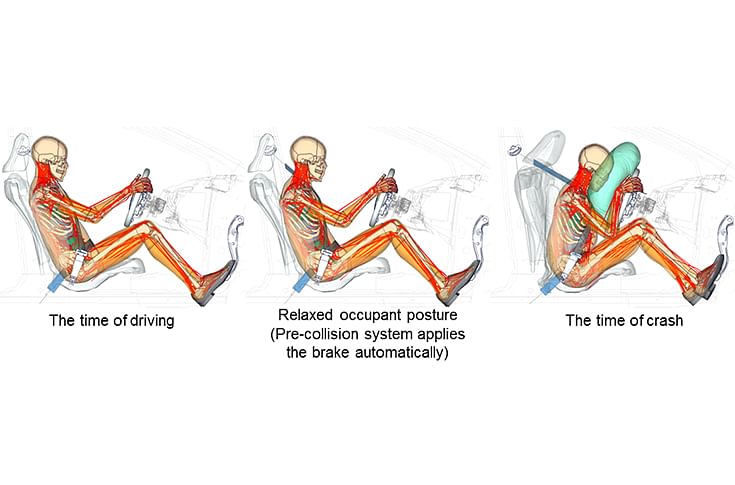

Toyota's Total Human Model for Safety (THUMS) simulates detailed computer analysis of human body injuries caused by vehicle collisions

The cars received a four-star rating in the frontal crash, conducted at 64kph. The Etios Liva was certified as stable in the test and offered good overall protection for adult passengers. The same car scored three stars in child safety, where Toyota-recommended child seats were used.

It is noteworthy that much before the crash conformance deadline of October 2017 for new models came into picture, TKM had equipped all its cars on sale in India across segments with dual airbags and ABS as standard. Progressively, the manufacturer set another precedent of making a whole of seven airbags, ABS, EBD and ESC standard in its Yaris C-segment sedan launched last year.

Observing the growth curve of each of these OEMs in India, in terms of improving safety in their products, it is quite evident that the safety environment in the country is set to witness a paradigm shift in the coming times. Although a little late, the regulations are bringing competitors on a level playing field to keep the consumer at the pedestal of receiving the highest quality products.

Reverse parking sensors are set to become mandatory from July 2019. The sensors that activate when reverse gear is engaged provide an audio/visual warning of an object in the path of the car

All this will be further testified when we finally see India eventually getting its own well-structured Bharat NCAP, which will act as a safety watchdog against the defaulters, just in case there are any in the future.

(This article was first published in the April 15, 2019 issue of Autocar Professional)

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

08 Jun 2019

08 Jun 2019

39564 Views

39564 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi