Partner Content

Manufacturing innovative polymer-based components for automotive applications

Mutual Automotive Pvt Ltd. specialises in injection molding, fibre injection molding, gas-assisted injection molding, hybrid thermoplastic composite molding and injection compression molding.

Mutual Automotive Pvt Ltd. provides the automotive industry with innovative state-of-the-art manufacturing solutions in engineered polymer-based components, systems and related services.

The company supports Engineering Design right from the concept stages to development, thereby helping us achieve supremacy as a wholly integrated unit.

Our core activities include, Design and Engineering Full Service Supplier (FSS), Tool Manufacturing, Injection Moulding, Painting, Aquagraphic Decoration, System Assemblies, End of line Testing and supplies in JIT and JIS. We are equipped & skill to prove performance.

The company’s offerings is backed by over 4 decades of experience and expertise in developing and processing plastic components. Mutual Automotive has added a design & engineering centre to support customers with end-to-end solutions from part concept stage to mass production and system supplies.

The client list includes Indian and Global OEMs like Tata, Mahindra, Stellantis, VW Group, Toyota, Honda, GM, Ashok Leyland, KTM, Piaggio, Force Motors among others.

Various plastic polymers

We process plastics across a wide range of polymer families right from polyolefins to Engineering polyamides, styrenes and various special compounds to meet the precise needs of the parts using injection moulding technology. Our group tool room supports shorter programme/product development cycles with an in-house Mould Design & Development shop. The tool shop comprises of a fully equipped 5 Axis (CNC) based machine shop, EDM and assembly set up capable of manufacturing moulds for parts of sizes up to 3 m x 2 m with a weight of up to 50 Metric Tons.

Mould capabilities

With our capabilities we can mould various automotive parts from sizes as small as a button to as large as the front hood of a heavy commercial vehicle addressing both the technical and aesthetic requirements of the products. We pride ourselves in employing the most contemporary technology in our machines ranging up to 3,200 tons across reputed brands in the industry. We also have the expertise of manufacturing with long fibre injection molding, gas assisted injection molding, hybrid thermoplastic composite molding, injection compression molding.

Investment in technologies

In keeping with our commitment of state-of-the-art infrastructure and to provide our customers nothing but the best, we have invested heavily in the latest Aesthetics finishing technologies and are a house of excellence for plastic parts surface coating. In India we were the first to foresee the need within the automotive hangout parts for fully automated surface coating processes equipped with robotic paint application systems and the first five-stage power wash. Our facilities have the ability to process all solvent borne and water-borne paint technologies with the expertise to produce primer less products that surpass customer expectations.

Just-in-time equally important

At Mutual, we recognise the need to deliver a complete system with Just-In-Time (JIT) and Just-In-Sequence (JIS) logistics to cater to OEM’s supply chain requirements. We have the capability to handle plastic part assemblies with bought out components, electrical and electronic parts into a system, delivered directly into the OEM assembly lines. Based on the need of the products and logistical requirements, we deploy dedicated assembly cells with manual, semi-automatic and fully automated processes. Our assembly lines are augmented with contemporary technologies in plastic welding, robotic ultrasonic welding, vibration welding, mechanical fastenings, PAD printing, usage of SPMs and other related techniques. We can deliver completely assembled products to your distribution network as a contract manufacturer.

Aquagraphics & advanced aesthetics is our speciality

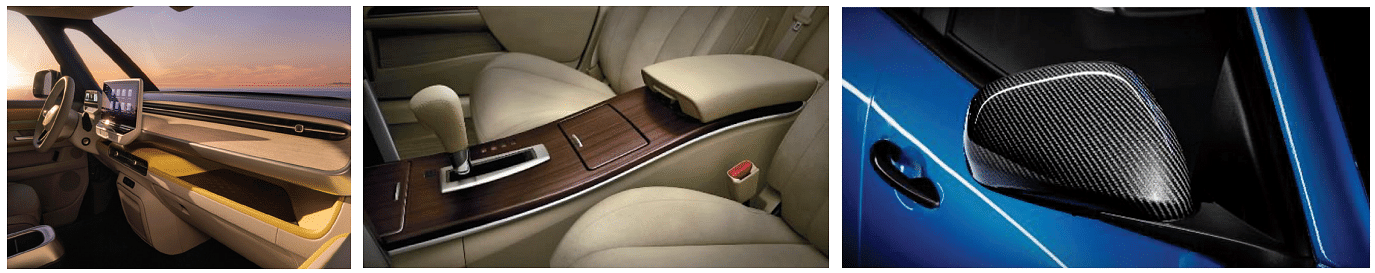

Mutual Automotive brings technology that enables transformation of your products through surface enhancement to augment its beauty. The process called Aqua graphics entails a water-soluble film, covered in natural and abstract prints that is printed onto substrates which could be made out of plastic, glass, wood, metal etc. It is possible to create thousands of different patterns across various colour and shades on the products. Aqua graphics finds excellent applications in automotive interiors & exteriors, 2-wheeler components, home electricals, home appliances, personal case packaging, architectural products, etc. The pictures show examples of applications of interior and exterior automotive applications which meets all the automotive Quality criteria and norms.

Mutual Automotive brings technology that enables transformation of your products through surface enhancement to augment its beauty. The process called Aqua graphics entails a water-soluble film, covered in natural and abstract prints that is printed onto substrates which could be made out of plastic, glass, wood, metal etc. It is possible to create thousands of different patterns across various colour and shades on the products. Aqua graphics finds excellent applications in automotive interiors & exteriors, 2-wheeler components, home electricals, home appliances, personal case packaging, architectural products, etc. The pictures show examples of applications of interior and exterior automotive applications which meets all the automotive Quality criteria and norms.

What type of r&d has gone to develop the tech?

Aquagraphics though commonly known as water-based surface decoration has many aspects of design technologies, which are generated by skill and adaptation of the surface contours. We have a team of experts who work on developing these skills and share their years of experience and opinions as input to various agencies abroad who work on the R&D and offer us materials as defined by our experts.

What investments have gone to develop the tech?

Investments in skill development are immeasurable, skills is never obsolete. Hardware has many aspects, including environment and control on consistency and quality. Production equipment as standard machines have a certain value, however, when the equipment is tuned and tailored for results, the cost is much higher than basic equipment.

What is your long-term plan considering rapidly changing technologies?

Products are continously changing and calling for new levels of performance and aesthetics. The long-term plan is to be prepared with solutions, before, such products appear on our tables.

Plans for expansion

We foresee customer growth and grow alongside. We have acquired basic infrastructure for expansion until 2026. Our developments are continuing in this direction. Our teams are continuously working with technology partners globally. We ensure that we are able to put before the customer with solutions that fit their product and marketing strategies.

RELATED ARTICLES

BKT, the ‘Off-Road King,’ Chases the Consumer Market

The company has unveiled a broad range of tyres for the Indian two-wheeler and CV markets.

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

By Autocar Professional Bureau

By Autocar Professional Bureau

02 Jan 2024

02 Jan 2024

7437 Views

7437 Views

Shahkar Abidi

Shahkar Abidi

Darshan Nakhwa

Darshan Nakhwa