Dharmesh Arora: 'We have solutions for all kinds of powertrain: conventional ICE, hybrids and pure EVs.'

Schaeffler India's Chief Executive Officer reveals how the company is uniquely positioned to cater to OEM needs of BS VI compliance, its readiness for vehicle electrification from hybrids to full electrics, how the state-of-the-art R&D Centre at Pune is thriving.

In an all-encompassing interview, Schaeffler India's Chief Executive Officer reveals how the company is uniquely positioned to cater to OEM needs of BS-VI compliance, its readiness for vehicle electrification from hybrids to full electrics, how the state-of-the-art R&D Centre at Pune is thriving on new product innovation for the domestic market, and lots more.

How is Schaeffler aligned with environment-friendly technologies, especially the ones relevant for the Indian market in the near future, and the ones that are or can be made in India for the world?

The mobility landscape is changing across the world and so is the case in India. There is a very high focus on making the future of the mobility environment-friendly. Within many modes of transportation, automobiles play an important role in providing convenient shared and individual mobility. With low current penetration, the Indian automotive industry is expected to continue to grow at a rapid pace but with increasing consciousness towards sustainability. Internal combustion engines (ICE) are becoming more efficient while hybrids and electric vehicles on the horizon promise to help reduce the overall carbon footprint. These changes are seen as a tremendous opportunity for Tier 1 technology suppliers like Schaeffler.

Schaeffler is one of the leading suppliers of products and systems that help reduce CO2 emissions and protect the environment. We do have solutions for all kinds of powertrain — be it conventional ICE, hybrids or pure electric vehicles.

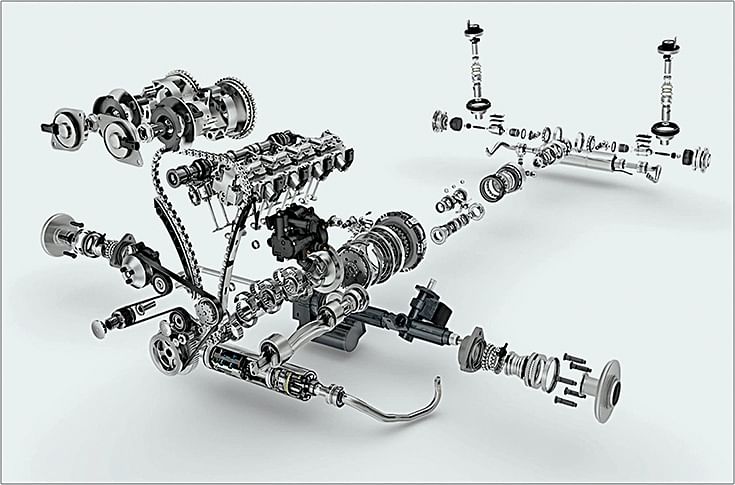

For ICE vehicles, we have advanced solutions for engines, transmissions and chassis that help reduce emissions, powertrains to become more efficient and reliable, vehicles to be more comfortable and fun to drive. These include all kinds of new-generation bearings to reduce friction, valve train systems, belt and chain drive systems, transmission synchronizer systems, range of clutches, dual mass flywheels and technologies for all kinds of automated transmissions.

As a global automotive supplier, Schaeffler’s portfolio includes products for the engine, transmission and chassis, offering OEMs an extensive modular kit

for tailored solutions and a tight supply chain.

For hybrid and electric vehicles, we have a range of solutions from mild hybridisation P0 to full electric vehicle solutions at P4. Our capabilities cover the complete system development including electric motors and power electronics. These solutions are catered to a very wide customer base ranging from passenger cars, two-wheelers, commercial vehicles and tractors.

When is Schaeffler expecting to begin mass production of BS VI-relevant parts at its plants in India?

BS-VI will be implemented in India from April 2020. Vehicle manufacturers have been working with us for a long time, preparing for this transition by upgrading the powertrains. From an engine point of view, Schaeffler’s focus is on improving combustion efficiency, reducing friction and thereby make powertrains inherently more efficient. For example, our solutions like Hydraulic Lash Adjusters and Roller Finger Followers help improve the overall efficiency while improving reliability. Similarly in valvetrains, increasingly the engines are using Cam Phasing systems that help improve the combustion efficiency in all driving and engine loading conditions. We see increasing use of technologies like these, manufactured by us, in meeting new emission laws.

One major trend is to make engines smaller towards reducing the overall emissions. While this is being done, the engines are becoming more powerful per unit of displacement, in order to not compromise on driving performance. We are helping engine designers achieve these conflicting objectives through many of our innovative solutions.

Engine designers also face the challenge that, as engines become smaller (for example, going from a four-cylinder to a three-cylinder engine), they have higher noise and vibration issues. Once again, our unique dampening solutions in clutches and dual-mass flywheels help OEMs overcome these challenges.

As a global player, Schaeffler is uniquely positioned and has a whole range of advanced technology solutions. Some of the very advanced technologies like switchable or fully-variable electrohydraulic UniAir valve control system, cylinder deactivation modules, and thermo management modules offer even greater opportunity for emission reduction, and we have customers in India exploring such technologies with us. These are globally proven solutions and as the market continues to evolve, we are bringing these solutions to India.

What will be Schaeffler India's mainstream products (high volume and high margins) that it will supply to its customers under the BS-VI regime?

As part of our outlook for a sustainable future, Schaeffler India is focused on developing and producing components and systems which provide maximum energy efficiency and lowest possible emission values. We have been developing advanced technologies in the areas of whole powertrain, engine and chassis to support the automotive industry’s stringent emission regulations and fuel economy norms. These essentially include engine air management systems including variable valvetrains, switchable valve trains, camshaft phasing systems amongst others. Locally, we have the whole range of efficient bearings, wide portfolio of Hydraulic Lash Adjuster (HLA), Roller Finger Followers (RFF), accessory drive systems and advanced dampening systems that continue to play important roles in increasing the efficiency of the internal combustion engines.

How does the company assess the demand for electric vehicles in India over the next five years?

Electric mobility as a whole — including fully electric driving and hybrid solutions — will be defining the mobility of the future. With the Indian government’s recent push towards electrification of vehicles with the announcement of FAME 2 scheme and a total budget outlay of Rs 10,000 crore as incentives for manufacturers to develop EVs and its components, we believe smart, connected EVs are the future and India will be an important global player in it. While it is inevitable that an increasing number of automobiles of the future would be electrified, starting with the ones used for shared mobility, the pace of change for privately owned vehicles would depend on many factors in the ecosystem including infrastructure and affordability.

Dharmesh Arora visiting a Schaeffler facility

Our view is that by the year 2030, up to 30 percent of vehicles would be fully electric while the remaining 70 percent would still be having an IC engine, either by itself or in combination with electric motors as in hybrids. There is still a tremendous opportunity to continue to improve the efficiency of IC engines in order to make appreciable impact on the environment for immediate future. There is a roadmap planned by the society and legislatures alike on further tightening the regulatory requirements through Corporate Average Fuel Efficiency (CAFE) norms and CO2 reduction norms of the future.

At the same time, Schaeffler is preparing itself to participate in the electrification journey, as it happens. In India, we have taken steps to build capabilities around the theme of e-mobility. Our diverse product range includes offering electric axles for a 48-volt hybrid to plug-in hybrids to pure electric vehicles. We have been working on electric powertrain solutions and are continuously investing in developing capabilities in mechatronics and software areas which can support the future e-mobility needs of our customers.

Will Schaeffler participate in the electric two-wheeler space? If yes, what products is the company looking to supply?

India is the world’s largest two-wheeler market and continues to grow at a rapid scale. Despite a recent slowdown in the Indian auto industry, the domestic two-wheeler industry posted a double-digit growth of 12.8 percent in 2018. Electric two-wheelers showed a substantial growth of 138 percent during the same period, albeit from a very small base. The two-wheeler segment is ideally positioned to lead the technology transformation from ICE to electric in India, since many of the transformational challenges like the infrastructure are much easier to overcome for this segment. We have a very strong presence in ICE two-wheelers and have set up a two-wheeler product development hub in India to address the unique needs of our Indian customers.

Considering the Indian market, we have a few programs running within the R&D space such as Twin-Tran, a unique two-speed automatic transmission solution, coupled with an efficient electric motor for application in two- and three-wheelers. Developed by our two-wheeler R&D hub in India, the technology enables seamless multi-speed transmission, leading to increased vehicle performance and enhancement of overall efficiency of the electric powertrain. Solutions like these would enable the electric propulsion to complete effectively with the current ICE propulsion either for performance or for range, depending on customer preference.

What is the update on the upcoming global competence centre of expertise for two-wheelers up to 250cc, agriculture and farm equipment including tractors? When will the centre commence operations?

The Schaeffler Group is bullish on innovation and shaping the mobility for tomorrow through advanced technologies and new-age sustainable products. As such, we are continuously carrying out various innovative R&D projects to develop new products. We have already established an Incubator Competency Centre at our Pune plant for two-wheelers and agricultural machinery, wherein we are already working on several local innovation projects leveraging local competency, infrastructure and local networks.

We are constantly engaging with local customers for concurrent engineering for those concepts. As we make progress in our projects and create success stories, we will expand our bandwidth and infrastructure. Last year we opened a new state-of-the-art R&D Centre at Pune that houses both of these hubs. The centre, which is now approved by DSIR, is doing some fantastic work to address the challenges faced by Indian customers.

Can you tell us about the investments Schaeffler plans to make in India in the near future and where will they be allocated?

In terms of investments at an India level, we have invested around 18-20 million euros (Rs 140-155 crore) per year in the past. With the merger of our three group entities into 'One Schaeffler', we see tremendous growth opportunities in India, across both the automotive and industrial sectors. As such, since the last one year, we have doubled our investment in India and plan on similar investments in the coming years. Our investments are aimed towards expanding our engineering and product capabilities in terms of plant capacities, vast product portfolio, creating R&D and innovation hubs, in order to meet the BS VI and CO2 emission norms, helping OEMs to upgrade powertrains, and prepare ourselves for the future. We will invest in our distribution network and all the logistics areas which will provide us substantial benefits in the long run.

Similarly, we will continue to invest and develop capabilities to provide technical solutions across sectors including automotive emission reduction, transmission automation, railways, wind, steel and infrastructure and more.

Do throw some light on Schaeffler's strategy and market play under its forecast of 30-30-40, which represents pure EVs, pure ICE vehicles and hybrids respectively by 2030. How is the company replicating this approach in India?

Our prediction at Schaeffler is that in 2030 around 30 percent of all newly registered passenger cars will be fully electric, while 30 percent of the vehicles would still be internal combustion engine- (ICE) driven and the remaining 40 percent propelled by hybrid powertrains (a combination of a conventional IC engine and an electric motor). Therefore, 70 percent of all passenger cars will be electrified using an electric motor while still 70 percent will still be equipped also with an ICE engine! While there is no doubt that EVs and hybrids will continue to grow, there is ample room for improving the efficiency of ICEs. More importantly, technology suppliers like us can utilise this opportunity to help our customers make their powertrain compliant to meet BS VI, new Corporate Average Fuel Efficiency (CAFÉ) norms or CO2 reduction norms of the future.

On the other hand, while we all agree that the internal combustion (IC) engines would continue to play a very important role in creating sustainable mobility for several decades to come, the push to transform the mobility space by the Indian government is commendable. As such, as part of our global ‘Mobility for Tomorrow’ strategy, Schaeffler India is taking all the necessary steps towards building capabilities around the e-mobility theme. We at Schaeffler India have focused our efforts on two- and three- wheelers that play a very important role in India, providing personal mobility and last-mile connectivity.

We have been working closely with the Group on gaining knowledge on electric powertrain solutions and are continuously investing in developing local capabilities in mechatronics and software areas which can support the future e-mobility needs of our customers. Our strategy is to continue building stronger business in conventional ICE and while ensuring that as India moves to electric mobility, we would be able to bring the already developed solutions into the country quickly.

What are the company's immediate priorities for FY2019-20?

Following the merger of our three entities — INA Bearings India, LuK India and FAG India — into Schaeffler India Limited, our combined India operation has become the leading automotive and industrial supplier in India. The consolidation of our operations, revenues and employees has made us more efficient, increasing our ability to serve our customers in a better manner.

However, the merger has also thrown up larger responsibilities and the priority is to truly synergise the capabilities of the three groups and imbibe the culture of One Schaeffler across the entire organisation — be it production, sales function, supply chain function and so on. Hence, our immediate focus lies towards developing a deeper integration of the merger across all functions of the organisation which would help us in consolidating our position as leaders in the industry.

Furthermore, Schaeffler India is driven towards shaping the Mobility of Tomorrow. We are highly focused on emerging technologies such as electrification, digitisation and increased level of competency for mechatronics under the R&D space and are continuously investing towards the development of advanced capabilities in these segments in preparation for driving future growth of the company.

In the short term, we also see some softness in the automotive industry while at the same time many predict a very strong pull towards the end of 2019 by way of pre-buying due to the impending implementation of BS-VI. The organisation should be prepared for this expected volatility. This is the focus on our current business, and without a very strong and effective current business, no company can afford to invest in the resource-heavy disruptive changes of the future.

(This interview was first published in the June 15, 2019, issue of Autocar Professional)

RELATED ARTICLES

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

TVS Celebrates 20 Years of Apache, Eyes Premium and Global Push

Marking two decades of its flagship performance brand, TVS Motor unveiled special anniversary editions on Saturday while...

Q&A: Mahindra's Nalinikanth Gollagunta on Upcoming Festive Season, 'Bold' Design Choices

Automotive Division CEO Nalinikanth Gollagunta says mid-teens growth is achievable with Roxx ramp-up, BEVs, and a resil...

By Autocar Professional Bureau

By Autocar Professional Bureau

24 Aug 2019

24 Aug 2019

31441 Views

31441 Views

Prerna Lidhoo

Prerna Lidhoo

Darshan Nakhwa

Darshan Nakhwa