Shortage of quality electrical parts a challenge to localisation of Camry Hybrid

Toyota Kirloskar Motor (TKM) has taken a leaf from the FAME India programme that was recently launched by the Indian government to drive growth of electric and hybrid vehicles in India.

Toyota Kirloskar Motor (TKM) has taken a leaf from the FAME India programme that was recently launched by the Indian government to drive growth of electric and hybrid vehicles in India.

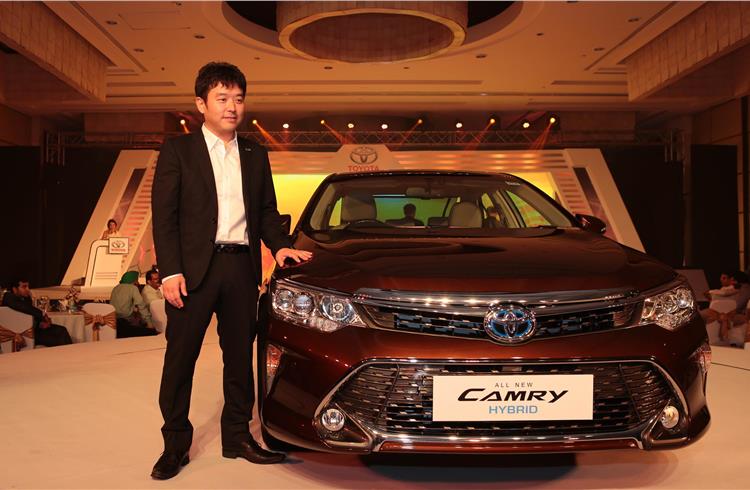

The Japanese car manufacturer today rolled out its all-new Camry Hybrid and Camry petrol models, priced at Rs 31.92 lakh and Rs 28.80 lakh respectively (ex-showroom Delhi), putting as it were its cards on the government’s ‘Make in India’ mantra.

Once the financial incentives under FAME become operational, which will be soon, according to Naomi Ishii, managing director of TKM, an incentive of Rs 70,000 on each Camry Hybrid will further cut the price of the car by that amount.

In CY 2014, the Toyota Camry had sold 720 units in India of which the hybrid model, introduced in August 2013, contributed 73 percent or 523 units, indicating that the Camry Hybrid had caught the fancy of some wealthy, ‘green’-minded buyers in India.

The Camry was first introduced in India in 2002 with local manufacturing kicking off in 2012 of the seventh-generation petrol model at TKM’s plant II in Bangalore. The company set a milestone of sorts when it locally produced the Camry Hybrid from August 2013 onwards with the company claiming it to be India’s first ever locally manufactured hybrid car. Plant II that also produces the Etios, Liva and Corolla Altis has a separate line for the Camry with a very specialised team working on it.

“Each team member has been skilled and trained in Japan to produce the Camry, so capacity is not a constraint. The Camry is produced in 11 plants worldwide and the Bangalore plant has very motivated and skilled members to build the Camry of a super level,” added Masato Katsumata, chief engineer Camry, Toyota Motor Corp.

Globally Toyota has sold over 7 million hybrid cars in the last 15 years. TKM has sold more than 8,000 Camrys since the car’s launch in India. The company maintains that its Camry Hybrid has been well-accepted in India where there is an increased awareness about hybrids.

The Camry Hybrid comes with Toyota’s hybrid synergy drive powertrain and, according to the company, combines the performance of a 2.5-litre Atkinson cycle four-cylinder petrol engine and a high-torque electric motor.

Delivering fuel efficiency of 19.16kpl and 122.8gm of CO2 emissions per kilometre of driving, which is lower than conventional vehicles of the same engine size, the Camry Hybrid is equipped with an electronically controlled continuous variable transmission to counter NVH and high fuel consumption.

The full hybrid Camry is a self-charging car unlike an EV. When the vehicle decelerates or at the time of braking, the electric motor acts as a generator and converts the kinetic energy to electric energy in a process called regenerative braking. This energy is stored in the Camry Hybrid’s HV battery pack for later use when needed to power the car.

The saloon has an air-conditioning system with three zone controls, a pollen filter and breakthrough nano water coated ion technology that enables a moisturising effect to the occupant and deodorises the cabin.

With the new Camrys in its stable, TKM is looking to end this calendar year with domestic sales in the range of over 135,000 units with a market share of around 5 percent in India.

TKM visualises a peak opportunity of growth in India in the next 5-10 years “but we have to grow in a very sustainable way keeping in mind the three big problems in India – energy security which means we have to bring a lot more fuel efficient cars, second is the air pollution which calls for bringing clean cars, and thirdly safer cars. So the auto sector has to keep introducing fuel efficient cars with the best of safety features. That is how we want to contribute towards the growth in India,” said Ishii.

Localising the Camry Hybrid

At present, the Camry Hybrid has low localisation content roughly estimated to be in the range of 20-30 percent value-wise. Hence exporting it to other BRIC markets is not cost-efficient at the moment. The Bangalore plant has flexible production capacity which can handle increased demand in the future but right now it is pegged at 110 units per month, of which 90 percent is the hybrid version.

“To localise the Camry Hybrid, we have to localise a lot of electricals and electrical parts in India. Unfortunately, India is very weak in this area, not only for automotives but for other segments like smartphones as well. There is a need to enhance the suppliers for it as well as have a stable electricity and power infrastructure. Swacch Bharat and Make in India will provide a perfect combination for it,” elaborated Ishii.

Therefore, a dramatic upgradation of infrastructure for producing electrical parts in India is the need of the hour and the government’s help would be needed to create a suitable environment. Here, TKM also cites regulations as being a major irritant as India is changing its regulations very quickly. This does not help as development of a new car model requires at least 4 years of intensive planning, development work, preparation for production and launch. “So clarity on regulations makes it easier. New products should be very well considered and should answer the requirement for a sustainable future and not only of today.”

Ishii said that TKM is working on a 4-year product development roadmap which would show results from 2017-18 onwards.

The carmaker has currently invested in a production capacity of 310,000 units in both its plants in Bangalore. With 50 percent utilisation, there is enough scope for further expansion without any major investments over the next 4 years. Last year, TKM saved a few hundred million rupees by improving operations in energy consumption particularly. By motivating the workforce and following kaizen practices, it was able to reduce costs and make the company profitable last year.

In terms of the narrowing petrol-diesel price differential, Ishii said that though there is some fluctuation in the price of petrol there is no major change. TKM, which is very strong in its diesel portfolio, does not have any immediate plan to change its product basket structure. Currently, the Etios constitutes 70 percent diesel, the Corolla is equally divided between the two fuels, the Innova and Fortuner are 100 percent diesel while the Camry is 100 percent petrol-driven.

RELATED ARTICLES

Uniproducts India targets 15% growth till FY2027, eyes new EV OEMs for NVH parts

The Noida-headquartered company, which is a leading manufacturer of roof liners, floor carpets, sound insulation materia...

Ford to build more EV software capability at Chennai tech hub

Ford Business Solutions India, which currently employs 12,000 personnel set to add 3,000 more; Ford, which is known to b...

ASK Automotive to set up JV with Aisin to sell aftermarket parts for cars

Ask Automotive will have 51% of the equity of the joint venture to be set up with Aisin Asia (Thailand) Company and Aisi...

30 Apr 2015

30 Apr 2015

4607 Views

4607 Views

Autocar Pro News Desk

Autocar Pro News Desk