ZF rolls out millionth AS Tronic Automatic Transmission

ZF has rolled out its millionth AS Tronic, the automatic transmission system for heavy commercial vehicles.

ZF has rolled out its millionth AS Tronic, the automatic transmission system for heavy commercial vehicles. One million units of the world's most successful automatic transmission have come off the production line at the ZF location in Friedrichshafen since production got underway in 1997.

"For almost two decades, commercial vehicle manufacturers around the globe have been relying on ZF's AS Tronic transmission range when it comes to automatic gear shifting," says Fredrik Staedtler, head of ZF's Commercial Vehicle Technology division based in Friedrichshafen. "It is considered a milestone in drive development and has meanwhile become indispensable in modern-day commercial transport."

ZF developed the first fully automated commercial vehicle transmission with the AS Tronic in 1997. Apart from the then development partner Iveco, today numerous other major international truck manufacturers put their trust in the automatic transmission system by ZF. However, the low-wear AS Tronic is also used in coaches, construction equipment, and in rail vehicles.

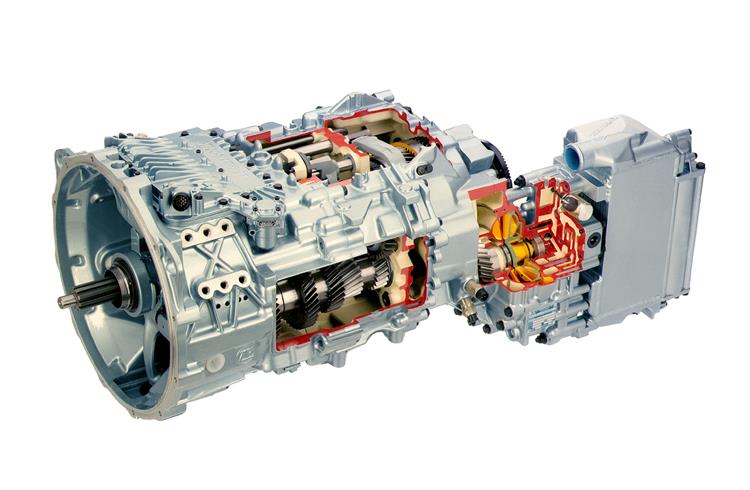

While the driver had to preselect gears manually on the early semiautomatic AS Tronic transmission, the second generation of the transmission launched in 2000 relieved the driver of the need to change gear: Automatic gear selection and electronically controlled gear changes reduce the strain on the driveline, thus increasing the service life of the driveline components. By networking transmission electronics and engine management via the CAN bus, the gearshift strategy used by the ZF-AS Tronic always ensures the engine operates in the optimum speed range. In this way, the power is transmitted very efficiently – thereby saving fuel – to the drive axles.

Gradual expansion of transmission range

An entire AS Tronic transmission range is now available, covering a torque range between 500 and 3100 Newton metres. The AS Tronic lite (500 to 1100 Nm) and the AS Tronic mid (800 to 1600 Nm) are mainly used in light delivery trucks, buses, and medium-duty commercial vehicles, while the larger members of this transmission family are suitable for heavy trucks and construction vehicles.

With its 12 speeds, the AS Tronic covers the torque range from 1600 to 3100 Nm while the 16-speed version offers a particularly fine spread of gear ratios for engines with up to 2600 Nm. The entire AS Tronic family can be combined with the Intarder, ZF's transmission brake. This can be integrated fully into the transmission thanks to its compact design. Inside the transmission, the Intarder not only boosts the engine braking power, but also reduces the workload of the service brake by up to 90 percent – particularly on long downhill stretches. All of which enhances safety as well as reducing the impact on the environment and lowering maintenance costs.

Successor ready for rollout

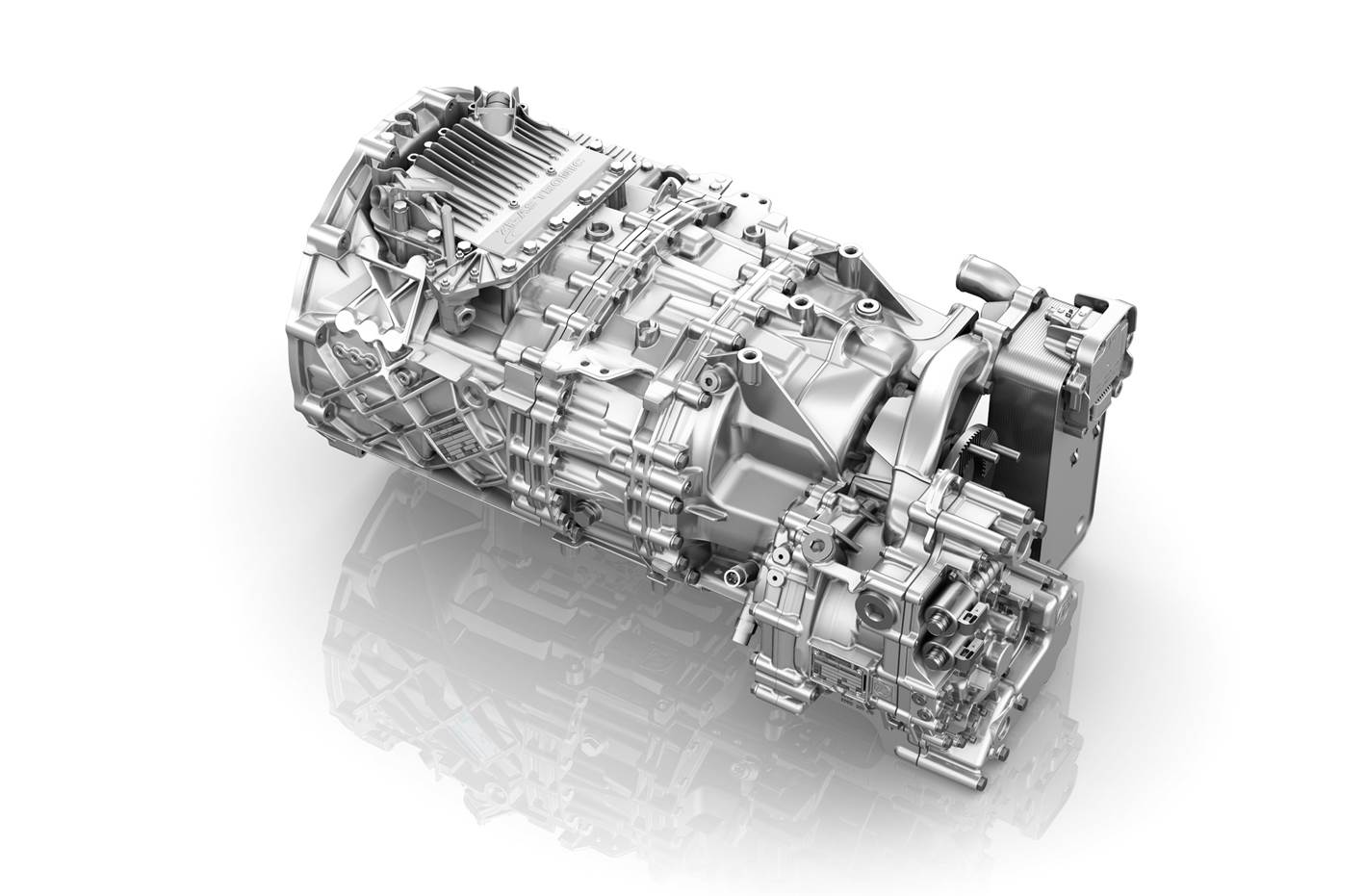

Coinciding with the production milestone of the AS Tronic, ZF has readied TraXon, the modular automatic transmission system, which will be produced at the Friedrichshafen plant and will gradually replace the AS Tronic over the next few years.

The all-new basic transmission is suitable for torque requirements of up to 3500 Nm and can be linked to five modules. The new system features an anticipatory shifting strategy courtesy of PreVision GPS. This enables truck manufacturers to link up the transmission with GPS data and digital map material. In this way, unnecessary gearshifts can be avoided – for example when a conventional transmission control unit shifts up a gear before an uphill gradient or a narrow bend, just to shift down to a lower gear shortly after.

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

19 Mar 2015

19 Mar 2015

6137 Views

6137 Views