Torsional welding tech helps join thinner materials, enables 10% weight reduction

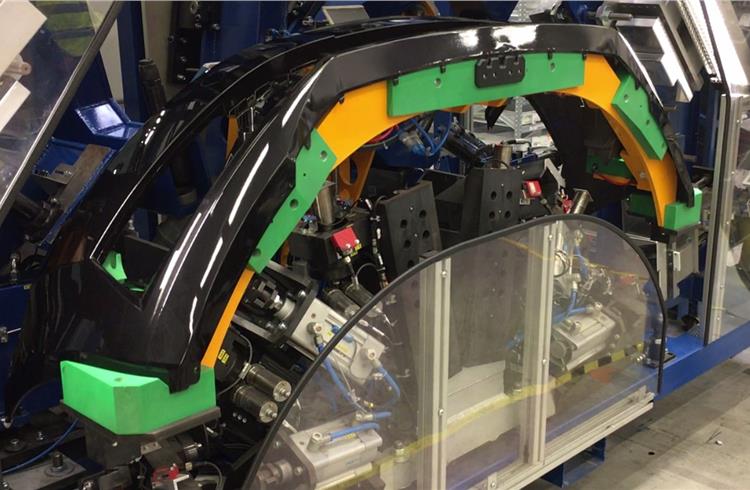

The torsional welding process, developed by Magna for automotive applications at its exteriors plant in Liberec, Czech Republic, presents a new way to join plastics.

Magna has put a new twist on joining thermoplastic materials in order to enable automakers cut weight and costs: torsional welding.

The torsional welding process, developed by Magna for automotive applications at its exteriors plant in Liberec, Czech Republic, presents a new way to join plastics. It features a high-speed twisting motion that creates enough friction-based heat to join a plastic bracket to a thermoplastic fascia.

The innovative technology achieves an approximate 10 percent weight reduction because it allows thinner materials to be joined, which in turn reduces material costs. Torsional welding is currently used to make the front fascia of the 2017 Skoda Octavia, and it has potential for other applications where materials of similar composition need to be joined.

There may also be uses for torsional welding with the increase of advanced driver assistance systems and the development of self-driving cars. The trend will be for automotive fascias to become heavier with the increase in autonomous features, due to the addition of sensors. With torsional welding, it's now possible to reduce weight on the outer skin and brackets so more sensors can be added without impacting the overall weight of the vehicle.

The Society of Plastics Engineers Detroit Chapter recognised Magna's torsional welding process with an innovation award at its recent TPO conference in Troy, Mich.

"We seek every opportunity, from design and materials to enabling technologies, to help customers meet their lightweighting goals," said Magna Exteriors president Grahame Burrow. "We appreciate this recognition from SPE and look forward to expanding the use of this innovative process."

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

27 Oct 2017

27 Oct 2017

3127 Views

3127 Views