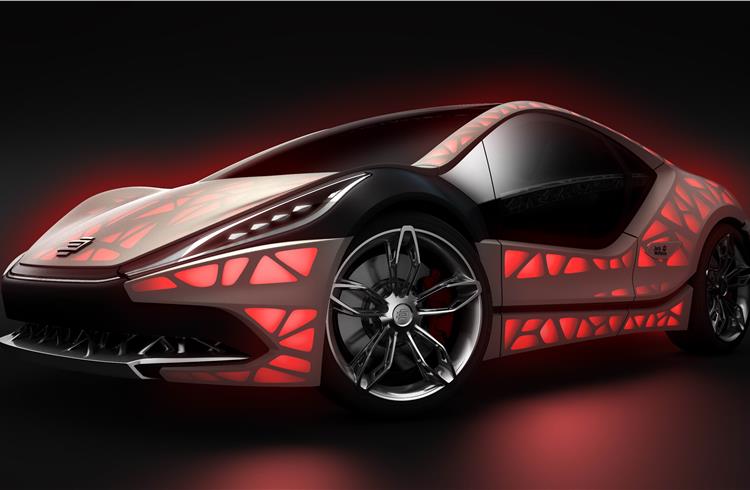

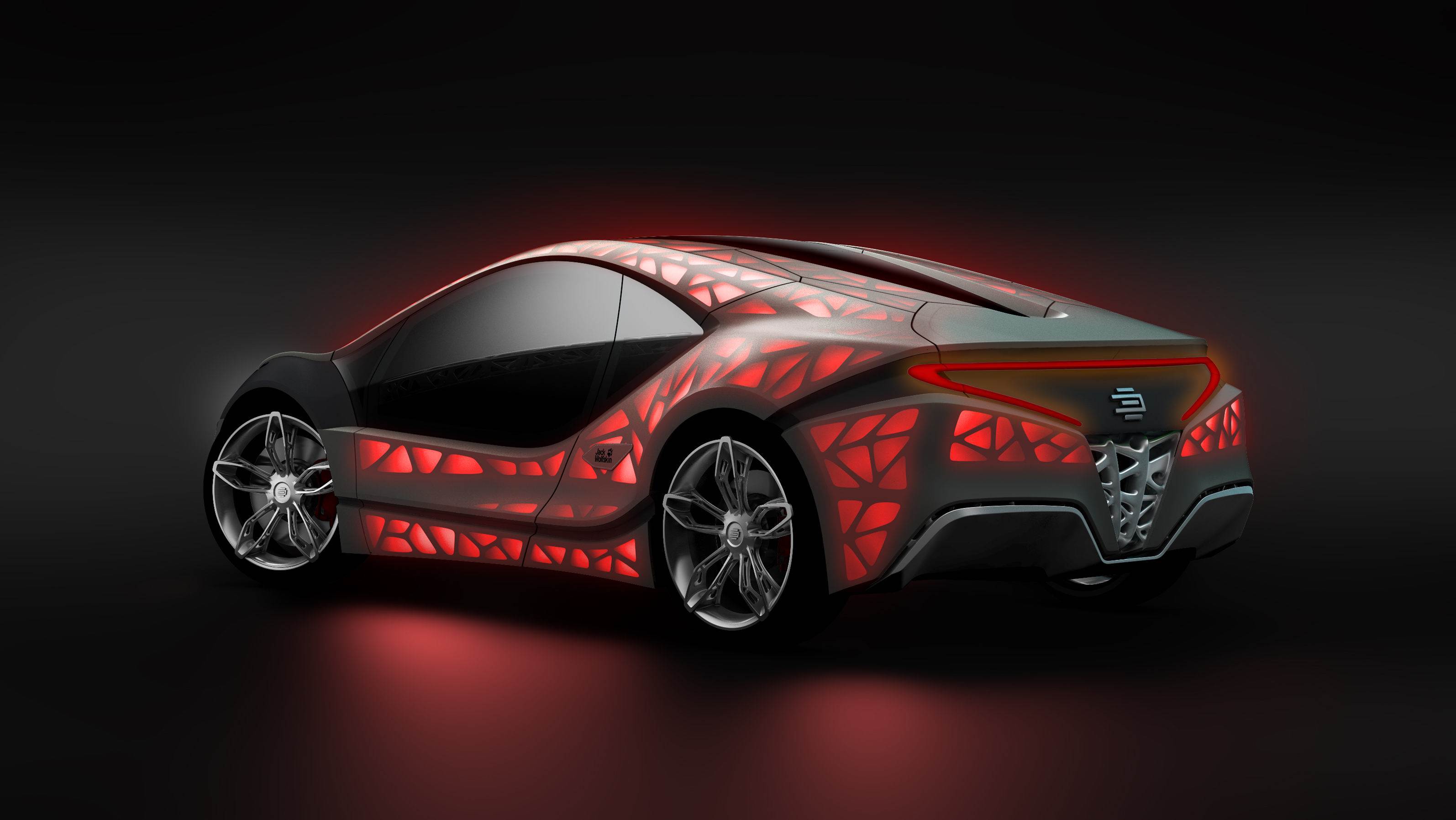

Super lightweight EDAG Light Cocoon to debut at Geneva Show

The EDAG Light Cocoon is a visionary approach towards a compact, dynamic sports car, with a fully bionically optimised, additively manufactured

The EDAG Light Cocoon is a visionary approach towards a compact, dynamic sports car, with a fully bionically optimised, additively manufactured vehicle structure combined with a weatherproof textile outer skin panel.

For this project, EDAG inked a partnership with outdoor specialist Jack Wolfskin whose extremely lightweight outdoor textile 'Texapore Softshell O2+' provides ideal weather protection for the EDAG Light Cocoon.

LED lighting technology installed behind the textile outer skin panel makes the vehicle's skeleton-like, organic structure visible, highlighting the vehicle's new, independent look to perfection.

"We are pursuing the vision of sustainability – as demonstrated by nature: lightweight, efficient, without any waste, and with a result that weighs considerable less," explains EDAG's head designer, Johannes Barckmann.

When the EDAG Light Cocoon was being designed, its body was not regarded as a closed surface. Instead, an approach was adopted in which material was only actually used in areas where it was necessary for function, safety and stiffness.

"The result is the EDAG Light Cocoon: a stable, branch-like load bearing structure which meets all requirements imposed on structurally relevant components, despite the fact that less material has been used," adds Barckmann. To first of all quantify and then verify the lightweight potential of a bionically designed structure, this approach had previously been used in the design of the bonnet of a production vehicle, and then calculated. In extremely lightweight concepts of this type any requirements regarding torsional and flexural stiffness and pedestrian protection must be met. The result was a spider-like, hollow structure designed for an assembly of aluminium profiles of different thicknesses. The calculation results confirmed two things: that the stability requirements were met, and that a weight saving of approximately 25 percent was achieved with this bonnet.

Natural look

The EDAG designers took to nature as their inspiration for the ultimate, lightweight outer skin. The leaf of a plant served as the blueprint for the innovative design of the body shell. Just like the structure of a leaf, which has a lightweight outer skin stretched over it, a lightweight protective skin covers the EDAG Light Cocoon albeit in this case, it is made of a textile fabric. Jack Wolfskin supplied a tried-and-tested stretch fabric that is also extremely weatherproof, to serve as the new outer body skin. "For us, the fascinating thing about the EDAG Light Cocoon is the combination of two technological innovations – the vehicle structure, fully bionically optimised by EDAG, and the lightweight Texapore Softshell O2+ weather protection material," said Elke Stein, Jack Wolfskin's director of marketing. "We see this as a chance to make an innovative mark beyond the limits of the outdoor sector – and EDAG is the perfect partner here."

Texapore Softshell O2+ is a triple-layered polyester jersey fabric, which is extremely lightweight, durable and watertight. The material's excellent elasticity is what qualified it for the bionic structure of the concept car as it can provide a perfect fit und accentuate it to perfection. Thanks to an LED back light concept, the interaction between light, structure and fabric created an attractive and innovative vehicle design.

"Even if it sounds futuristic to begin with, this approach has its own special appeal: weighing no more than 19 g/m², the Jack Wolfskin materials support maximum lightweight design requirements with minimum weight. Texapore Softshell, which is what we use, weighs just 154 g/m², making it one of the lightest Texapore materials on offer," said EDAG CEO Jörg Ohlsen. "Combined with the bionically inspired, 3D-printed structure, it offers enormous potential and stimulus for the ultimate lightweight construction of the future."

"With the futuristic concept of our EDAG Light Cocoon, we hope to stimulate the discussion about the future of lightweight construction and automobile production.

As an engineering company, we see it as our task to make sure that we are today already working on future technologies and completely new approaches to vehicle development. When it comes down to it, working on concept car projects like the EDAG Light Cocoon enables us to build up additional competencies within our teams, while at the same time also encouraging people to think outside the box and tread new paths in order to achieve the best possible technical solutions," explains Jörg Ohlsen, CEO of EDAG Engineering AG. "The focus of people like us, who develop the cars of tomorrow, must always be on the day after tomorrow."

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

30 Jan 2015

30 Jan 2015

3750 Views

3750 Views