Jaguar reveals all-electric I-Pace SUV Concept

Jaguar's all-new I-Pace Concept previews Jaguar’s first EV; expected to be on sale in 2018 and a rival to Tesla's Model X

The Jaguar I-Pace - easily the most radical car in its 81-year history - will vault the brand into central Tesla territory.

The all-new battery-electric SUV, unveiled as a concept at the Los Angeles motor show, changes practically every traditional Jaguar ingredient and is due on the road in about 18 months’ time. It marks the start of a bold new chapter in the engineering and design history of Jaguar Land Rover.

Jaguar’s brief for its long-anticipated first electric vehicle was to “create a performance SUV that is spacious, sporty and usable”, but the final design isn’t merely an electric version of the successful F-Pace SUV.

Instead, the I-Pace exploits the packaging advantages of an electric powertrain to marry a sleek four-door bodystyle with generous cabin space, four-wheel drive capability and performance on a par with a rear-wheel-drive Jaguar F-Type R.

The definitive production version of the I-Pace will be revealed at the end of next year, with most of the concept’s key features likely to be carried over. The car will go on sale in 2018 at a price expected to be about 10-15% above that of an F-Pace of similar specification, although Jaguar remains tight-lipped on pricing.

The I-Pace will take on Tesla’s Model X, the Audi e-tron and a production version of the Mercedes Generation EQ concept shown at the Paris motor show in September.

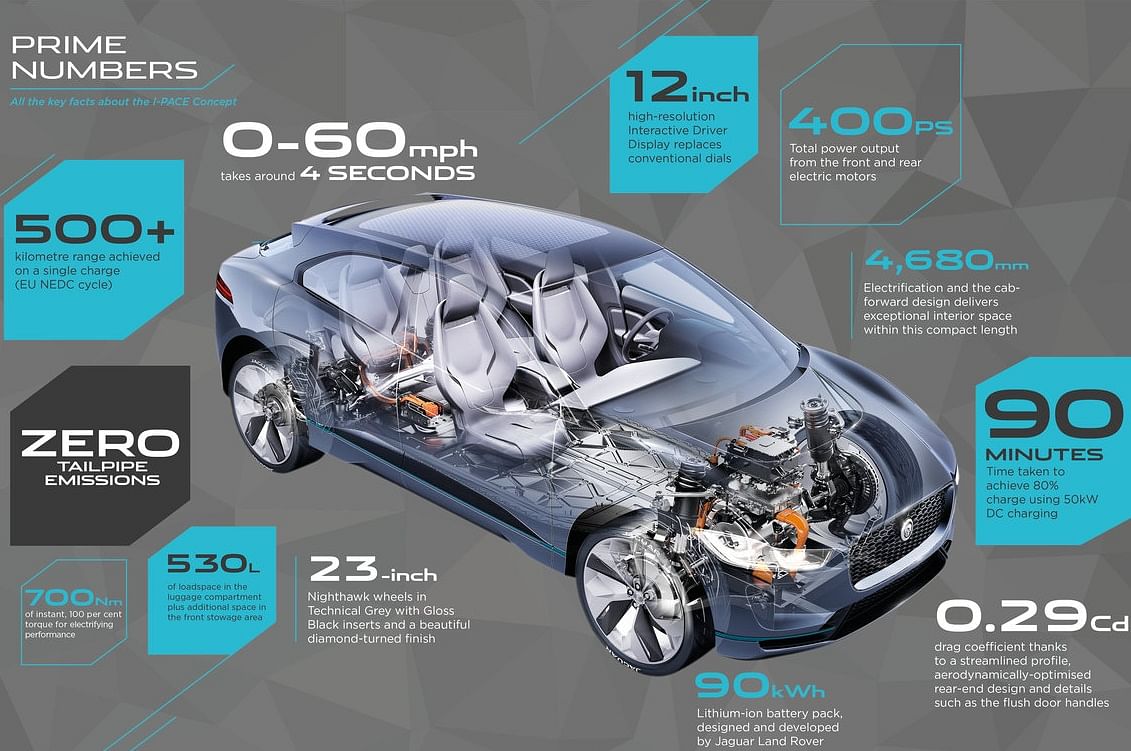

With some of the new Jaguar I-Pace Concept’s most interesting features lying beneath its surface, here’s an at-a-glance guide to the technology that makes up the new ‘skateboard’ chassis.

Battery Pack

The I-Pace Concept features a 90kWh battery comprising 36 modules which are enclosed within a structural aluminium housing.

Each module contains the latest lithium-ion pouch cells, which use nickel-cobalt-manganese chemistry. These cells were selected for their combination of high energy density and because they can maintain a higher current for longer, which means that the battery can deliver both driving range and sustained performance. Compared to some other cell types, they also offer considerable future development potential.

The battery pack is positioned as low down as possible and right between the axles, dropping the centre of gravity and enhancing vehicle agility.

Electric Motors

The car features two efficient, synchronous permanent magnet motors arrange concentrically with a single-speed transmission to make them as compact as possible.

Jaguar’s engineers designed and developed the motors in-house to achieve the compact design, efficiency and power density they desired. The motors have an outer diameter of 234mm, are 500mm long and weigh about 38kg each.

Integrated into the front and rear axles, with the driveshafts passing through the centre of the motors in a space-efficient layout, the two electric motors deliver a total output of 397bhp and 516 lb ft. The torque is on tap immediately as the vehicle pulls way from a standstill.

The two motor set-up also enables the new Jaguar concept with four-wheel drive, and the set-up means effective torque shuffling between the axles is possible, making the car adaptive to varying road conditions.

Like other hybrid and electric vehicles, the I-Pace features regenerative braking, which slows the vehicle down and recharges the battery in the process. The driver can adjust the level of regenerative braking via a button within the transmission controls on the centre console.

Battery Management System

The control system is fundamental to the I-Pace Concept’s performance and range by ensuring that the battery operates at optimum efficiency under all conditions.

A heat pump is an integral part of this system: by scavenging heat from the outside air to help warm the vehicle’s interior, the heat pump can deliver a double-digit increase in driving range - even in freezing winter conditions, when battery efficiency traditionally suffers.

The pack is liquid-cooled using a dedicated two-mode cooling circuit. In moderate ambient temperatures the battery improves efficiency by relying only on a radiator to remove the heat generated by the cells.

At higher temperatures the chiller linked to the vehicle’s main air conditioning system provides greater cooling capacity to keep the battery in optimum condition.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

15 Nov 2016

15 Nov 2016

12680 Views

12680 Views

Ajit Dalvi

Ajit Dalvi