Honda develops world’s first assembly line with a flowing cell production system

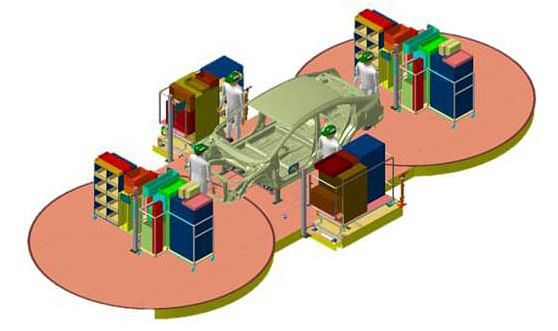

Four associates get aboard an ARC Unit, a unit of a conveyor that carries one vehicle body and a complete set of parts, and assemble the vehicle while moving along the production line together with the vehicle.

Honda Motor Co has developed the world’s first mass-production automobile assembly line with a main line that incorporates a flowing cell production system.

Honda has named this original assembly line the ARC (Assembly Revolution Cell) Line and introduced it to its new Prachinburi Plant in Thailand which became operational in March 2016. The plant is part of Honda Automobile (Thailand) Co Ltd (HATC), Honda's automobile production and sales subsidiary in Thailand, and is located within the Rojana Industrial Park in Prachinburi Province.

The newly-developed ARC Line is a world’s first innovative and unique assembly line that is different from a conventional line production system and was developed by incorporating flowing cell production-style production units in the main line. In production on a conventional line, which has been broadly adopted for automobile production to date, each production associate takes charge of a single process and installs parts to vehicle bodies flowing on a conveyor. In cell production, on the other hand, one production associate takes charge of a broader range of production processes and installs multiple parts.

In ARC Line production, four production associates get on board an ARC Unit, a unit of a conveyor that carries one vehicle body and a complete set of parts to be installed to the vehicle body, and assemble the vehicle while moving along the production line together with the vehicle. This system reduces any incidental movements by production associates - such as selecting the proper parts for the specifications of the next vehicle body coming down the line and installing them while walking along with the vehicle body. These are not considered essential assembly movements but are inevitable in conventional production processes. The ARC Line production achieves a significant improvement in production efficiency through the reduction of such process loss.

Moreover, with ARC Line production, each production associate takes charge of a broader range of production processes, which makes it possible for associates to gain a broader range of production knowledge and skills. This is expected to have a positive effect on the development of proficient production associates who will be capable of providing feedback from the production team to the development team in the future.

Also read: Honda ups the ante in ASEAN, opens new plant in Thailand

RELATED ARTICLES

Isuzu unveils D-Max EV at 2025 Commercial Vehicle Show

Revealed at the 2025 Commercial Vehicle Show in Birmingham, the Isuzu -Max EV is the first fully electric commercial pic...

Hyundai unveils next−gen highly efficient hybrid system

The next-gen hybrid system is claimed to offer 45% better fuel efficiency and 19% more power compared with ICE powertrai...

Horse Powertrain reveals hybrid conversion for electric cars

Engine-making joint venture of Geely and the Renault Group announces new hybrid powertrain that fits into the same space...

By Autocar Professional Bureau

By Autocar Professional Bureau

21 Apr 2016

21 Apr 2016

7773 Views

7773 Views