Ford cuts water use two years ahead of schedule

Ford Motor Company, which released its 15th annual Sustainability Report yesterday, says it is successfully reducing its environmental footprint.

Ford Motor Company, which released its 15th annual Sustainability Report yesterday, says it is successfully reducing its environmental footprint. It now plans to further its commitment to aggressively step up water conservation programs at its global facilities and among its suppliers.

In 2013, the manufacturer reduced per vehicle water use by 30 percent globally from a 2009 baseline, reaching its goal two years ahead of schedule. Plans are under way to further cut water use by another 2 percent this year and to set new long-term goals.

“As Ford continues with its largest global expansion in more than 50 years, the company also recognizes that working in regions struggling with water scarcity will soon make water a costly commodity,” said John Fleming, executive vice-president, Global Manufacturing and Labor Affairs for Ford Motor Company. “From a business perspective, understanding future constraints and immediately reducing Ford’s water consumption makes sense.”

In April, Ford president and CEO Alan Mulally endorsed the CEO Water Mandate to more clearly define the company’s mission. The private-public initiative launched by the U.N. Secretary General in 2007 requires participating companies to report their water management progress annually.

Later this year, Ford will begin asking high water-use suppliers and those working in water-stressed regions to voluntarily report water consumption and then work with them to achieve reductions.

The Cuautitlán Stamping and Assembly Plant in Cuautitlán, Mexico is an example of Ford’s success with water conservation. Built in 1964, the plant is located in a water-scarce region. Over the decades, the city has become host to many international corporations, including beverage companies that use large volumes of water. By 1990, the Cuautitlán government recognized that water demand was outstripping supply and began limiting water use and imposing stricter permitting. Changes implemented by Ford at the facility include installing dedicated piping for potable water to ensure it is used only for human consumption; recycling all other water used at the plant; and replacing asphalt with ecological concrete, which allows rain to reenter the ground. The result was an almost 58 percent reduction in water use per vehicle produced at Cuautitlán Stamping and Assembly Plant between 2000 and 2013.

“This is a success story we are very proud of,” said Luis Lara, manager of Mexican operations for Ford’s Environmental Quality Office. “When you are in a water-stressed region, you appreciate that having water is a precious thing. Any cubic metre of water we save at the Cuautitlán plant is a cubic metre of water available for people in the neighbouring communities.”

Ford says it began strategically working to improve the company’s water impact globally in 2000 by setting year-over-year reduction targets as part of its Global Water Management Initiative. The success of the initiative is measurable.

Not only has the company reached its water-use-per-vehicle goal two years ahead of schedule, it cut global water use by 61 percent, or by more than 10 billion gallons, between 2000 and 2013. That savings is the equivalent of a billion five-minute-long showers, according to the U.S. Environmental Protection Agency. The total amount of water used around the globe at Ford facilities fell from 64 million cubic metres per year to 25 million cubic metres.

Other highlights of Ford’s Sustainability Report include the sale of nearly 2.5 times more electrified vehicles in 2013 compared to 2012; its actions to increase supply chain transparency and ensure the minerals in its products are sourced responsibly; an 18 percent reduction of CO2 emissions in the European fleet between 2007 and 2013; and priority to accelerate new product development.

RELATED ARTICLES

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

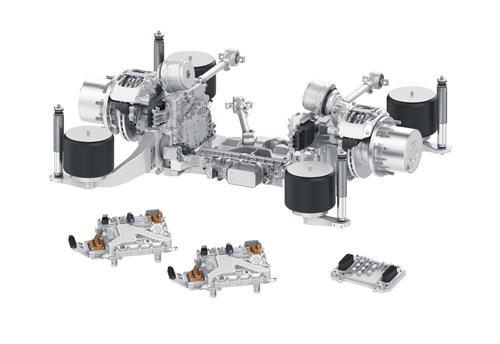

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

18 Jun 2014

18 Jun 2014

2827 Views

2827 Views

Autocar Pro News Desk

Autocar Pro News Desk