Daimler Trucks to invest half-a-billion euros in vehicle connectivity

The completely connected truck initiates a radical change in transport which will make road goods traffic even more effective and efficient for drivers, haulers, vehicle manufacturers and also for society as a whole.

Daimler Trucks, the world’s leading track manufacturer, is betting big on connectivity.

While 365,000 Daimler trucks around the world are already connected via the FleetBoard and Detroit Connect systems, the company is aiming for systematic connectivity of its vehicles ahead with all parties involved in the logistical and transport process. The completely connected truck initiates a radical change in transport which will make road goods traffic even more effective and efficient – not only for drivers, haulers and vehicle manufacturers, but also for society as a whole.

Daimler Trucks says it has been implementing this goal: since 2013 connectivity has been an established part of its corporate strategy. To this end the company is investing around half a billion euros (Rs 3,822 crore) in the connection of its trucks, and in the creation of associated new services and digital solutions, in the next five years alone.

Starting this year, it will continuously add new service packages to its already extensive telematics services, and also make its platforms accessible to third parties. The company has also set up the structural framework for the digital transformation of the truck business, and established corresponding structures in all business units.

Yesterday, on the A52 autobahn near Düsseldorf, Germany, Daimler Trucks presented an example of the possibilities opened up by the digital connection of trucks: Three WiFi-connected, autonomously driving trucks operated on the autobahn with authorisation for public traffic as a so-called platoon. Such a combination can reduce fuel consumption by up to seven percent and the road space requirement on motorways by almost half – while improving traffic safety at the same time. Based on the Daimler Trucks Highway Pilot system for autonomously driving heavy trucks, the three trucks link up to form an aerodynamically optimised, fully automated platoon. Daimler Trucks calls this advanced system development Highway Pilot Connect.

According to Dr Wolfgang Bernhard, member of the Board of Management of Daimler AG with responsibility for Daimler Trucks & Buses, “We are connecting the truck with the internet – making him the mobile data centre of the logistics network. It connects all those involved in goods: drivers, schedulers, fleet operators, workshops, manufacturers and insurance companies or authorities. They receive information in real time which was previously unavailable: about the condition of the tractor unit and semitrailer, traffic and weather conditions, the parking availability at motorway service stations, rest areas and much more."

"Our trucks fully connect with their environment, becoming part of the internet and continuously sending and receiving information. All those involved in the logistical process can use these real-time data for their needs. In the future it will e.g. be possible to reduce waiting times while loading and unloading, reduce paperwork and avoid traffic jams. With flash updates over the air or automated transfer of inbound time for trucks heading to the service point maintenance time can be reduced significantly. In this way we are considerably improving the performance of goods transport as a whole. An enormous opportunity to intelligently cope with the growing volume of goods traffic. We intend to use it," says Bernhard.

“Today Daimler lays the foundation for the third industrial revolution. In the era of the internet of things all tools and machinery will be equipped with sensors which constantly provide a real time information flow. This will fundamentally change the way we make business. The internet of things is offering completely new opportunities,” emphasises Jeremy Rifkin, author, sociologist and futurologist.

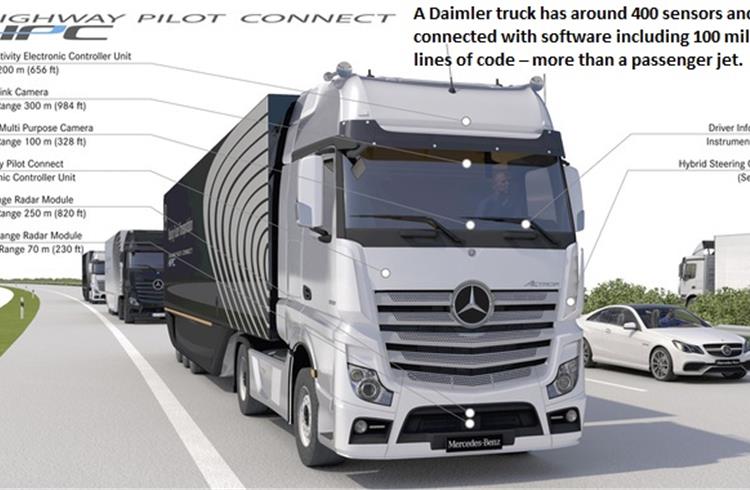

400 sensors register data of all kinds

The worldwide transport of goods is a prerequisite for economic growth. However, transporting more goods in the future requires innovative solutions if a traffic gridlock is to be avoided. One central approach is to fully network the truck with the internet of things. Daimler says its smart trucks have the potential to radically change road goods transport in the coming years. At present, the company generates information to a previously unimaginable extent with its approximately 400 sensors per vehicle and is fully connected with software including 100 millions of lines of code – more than a passenger jet.

Dr Wolfgang Bernhard: "For efficient logistics real time data are essential - and our trucks supply these data. Therefore we are investing around half a billion euros by 2020 to connect our trucks with their enviroment and develop specific new applications. This will enhance our customers’ performamce to operate their businesses safer and more environmentally friendly. FleetBoard and Detroit Connect will considerably help to leverage previously unharvested potential in road transport – both in the highly developed triad markets and in the emerging economies of Africa, Asia and Latin America."

New possibilities

The large volume of data which a truck can send and receive creates completely new possibilities for the entire logistics sector and society as a whole. Previously the different areas of the logistical network have been only inadequately connected. The information required for smooth-running procedures is often lacking, or it is not part of a network.

In Europe, for example, around 25 percent of all truck mileage is still on empty journeys. With new freight clearing houses based on data from connected trucks, logistics businesses will in future be able to utilise their vehicle capacity much better, and thereby reduce empty journeys. Another example: In 2015 German road users alone suffered around 568,000 traffic jams with a total length of around 1.1 million kilometres – and the resulting increase in fuel consumption and CO2 emissions. With the availability and exchange of traffic data in real time, trucks with intelligent sensors will in future be able to prevent rear-end collisions and circumvent traffic jams.

At the same time the downtimes of trucks can be reduced if the truck itself reports a fault at an early stage, and the hauler can schedule a service during the already planned downtime between two transport assignments.

Autonomous truck platooning lowers fuel consumption and CO2

With the world premiere of the Highway Pilot Connect system, Daimler Trucks gave a live presentation exemplifying the advantages of electronic vehicle-to-vehicle (V2V) networking on the A52 autobahn near Düsseldorf, and also of the next milestone in autonomous driving: the technology allows electronic docking by vehicles on motorways and long-distance highways, also known as platooning.

Connected vehicles in a platoon require a distance of only 15 instead of 50 metres between them. This considerably smaller distance produces a significant reduction in aerodynamic drag – comparable to slipstream riding in cycling competitions. In this way a platoon of three trucks can achieve a fuel saving of around seven percent, reducing CO2 emissions in the same measure. This makes fuel consumption figures of around 25 l/100 km possible for a loaded semitrailer combination with a gross weight of 40 t. This corresponds to a consumption of only 0.66 l/100 km per tonne, or CO2emissions of 13.3 g per kilometre per tonne. Well below the figures for any passenger car with an internal combustion engine.

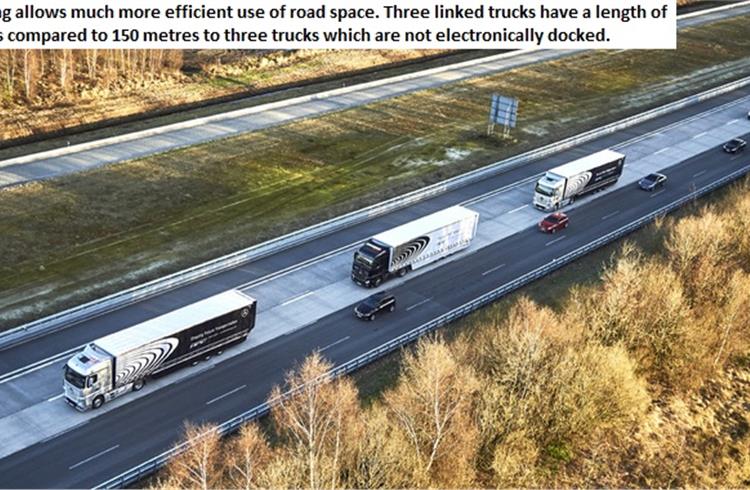

In parallel with this, platooning allows much more efficient use of the road space: thanks to the shorter distance between vehicles, a platoon of three linked trucks has a length of only 80 metres. In contrast to this, three trucks which are not electronically docked require a total of 150 metres of road space. At the same time platooning makes road traffic much safer: while a human behind the wheel has a reaction time of 1.4 seconds, Highway Pilot Connect transmits braking signals to the vehicles behind in less than 0.1 seconds. This considerably reduced reaction time can make a major contribution towards reducing rear-end collisions such as occur e.g. when encountering traffic jams on motorways.

"The smart, self-optimising truck has the highest priority for us. Using connected communication between the truck and other vehicles and the surroundings, we can improve traffic flow and lower fuel consumption and emissions. At the same time intelligent trucks help to lower the number of traffic accidents. This is an important step on our way towards accident-free driving," says Sven Ennerst, Head of Truck Product Engineering & Global Procurement.

Major advantage: automatic steering also when not connected to the platoon

The great advantage of Highway Pilot Connect is that because of their technology, all the members of such a platoon continue to be autonomously driving trucks. They are able to maintain their direction independently of the vehicle ahead, and thanks to their combination of linear and lateral guidance, they can react to unexpected situations at any time. This also applies if other vehicles cut into or leave the platoon's space. In this case the vehicle can smoothly disengage from the platoon and continue alone in autonomous mode. The driver does not need to intervene. Docking three or more vehicles together becomes particularly interesting in countries with a corresponding infrastructure. In the USA or Australia, for example, trucks cover long distances without bridges and exit roads on highways crossing the entire continent.

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

22 Mar 2016

22 Mar 2016

3421 Views

3421 Views